Medical assistance system

This year’s Gold award winner is a system that assists doctors with keyhole cochlea implant surgery to treat inner ear deafness and profound deafness.

DryLin® - Linear plain bearings move on gliding elements unlike the common recirculating ball bearing systems. These glide elements made of high performance polymers can in principle be produced from all iglidur® materials. For this reason, the advantages of the various iglidur® bearing materials are available for the DryLin® linear technology. However the iglidur® J is best suited for most linear applications due to its low-wear and low-friction properties. Hence the DryLin® linear bearings are equipped with this material. This application overview shows you highly varying application areas for maintenance-free linear guide systems made with the DryLin® range.

This year’s Gold award winner is a system that assists doctors with keyhole cochlea implant surgery to treat inner ear deafness and profound deafness.

This year, Bronze goes to a laser-based 3D printing machine that prints metal parts made of titanium, aluminium, steel or even gold.

This movable touchscreen system has been developed for quality checks in the company’s factories.

This handling and contacting module is used for the automatic electrical measurement of individual boards in the temperature testing cabinet.

This 3D printer was constructed with almost no ready-made components.

This automatic packing station packs labels in boxes.

This welding device disposes of several rotational positioned welding torches.

In this production in the Music Theatre Poznan, a laboratory table on stage needed to be extended in the middle of the scene.

The welding head of this welding set can be height-adjusted.

This device is used for physiotherapy treatment for back problems.

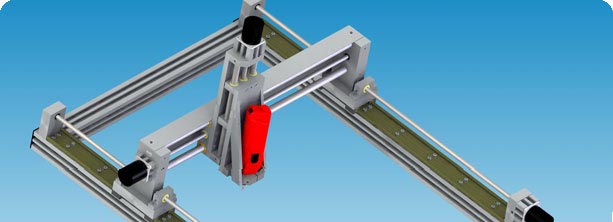

This student project deals with the development of an NC-controlled gantry for use as a multi-function machine tool.

Lubrication-free plastic bearings for ergonomic office chair

Sturdy lead screw linear system for extracting paper ice-cream cones.

Highly compact while traveling, very spacious at the campground, with the help of drylin® lead screw modules.

Lubricant-free, accurate, and very quiet: igus® components in 3D printers.

Clean, durable, and maintenance-free: polymer plain bearings in the food industry.

linear plain bearings for steering systems on bus trailers

This machine enables professional and time-saving mounting and removal of bicycle tyres.

Wear-resistant linear guides ensure 50 percent longer service-life for grinding tool machinery.

Gliding under the most demanding conditions. Stainless steel shafts, flanged and plain bearing for lab presses.

Dry-running linear guides and pillow block bearings lead to high service lives in wooden pallet production

Dry-running linear technology in diaper production systems

Lubricant-free lead screw units for a bottling plant in the medical technology

In this case, the use of igus® products is not only advantageous from a technical, but also from a financial point of view when compared to competitive products.

A builder of technical brush making machinery known world-wide, uses plain bearings from the igus® product range.

Low cost automation demo with robolink®, pikchain® and drylin® E

Lubricant and clearance-free lead screw nut system ensures precision glue dispensing on an edge-gluing machine

Plastic plain bearings in process engineering: Completely maintenance and lubricant-free.

By avoiding lubricants, the transported laminated pieces remain clean.

Only extensive earthbound testing can demonstrate the suitability of components for space applications.

Automobiles are parked and subsequently retrieved without the driver's involvement.

Freedom from lubrication and cleanroom compatibility can be ensured with the maintenance-free steep thread nuts.

Among other things, the weight of this laser marking unit could be halved by the use of drylin®.

The drylin® spindle lift table with position indicator and handwheel is used in a coder to label cheese because of its freedom from lubricants.

A maintenance-free drylin® liner guide system was used in a sideboard to move the upper elements in a flexible manner.

A drylin® linear guide has been opted in the production of a table due to its freedom from maintenance.

For the precision machining in laser engraving machines, several maintenance-free plastic components are used at once.

By the use of clearance-free pretensioned nuts in format changing systems in the paper industry, a precise and maintenance-free adjustment of the formats is enabled.

By using drylin® TR steep thread nuts in two chess computers, large strokes can be covered in the shortest possible time.

The solid worktop can be moved on glide rails, increasing the working surface of the desk.

In a very high quality watch safe, the sliding pull-out trays were implemented with linear profile guides.

Linear plain bearings in the transverse pull-out tray of a wooden tabletop.

Instead of using expensive 3D cameras, two regular cameras can be mounted on this device so that together they can generate a three-dimensional image.

With this 3D camera system „3D RIG“, the focus was on ease of movement and maintenance freedom.

This application from the field of medicine is an analysis device that helps to diagnose different types of cancer at an early stage.

Noise-free and precise DryLin® T-rail guides provide clearence for adjusting the height of the work tables.

For this reason, DryLin® linear guides and igubal® KSTM pedestal bearings are used; these need no maintenance and are not affected by the aggressive asbestos either.

The vertically adjustable examination table has been designed for eye examinations.

This system can be used to convert any door to be opened automatically at the touch of a button.

This gate, which can be opened and closed automatically, is used in sport stadiums and is folded like an accordion.

This gripper picks up freshly baked goods from a conveyer belt and packs them in baskets.

This machine manages data back-up tapes. The transport movements inside are guided by DryLin® N linear guides.

This device measures the drilling resistance of a needle penetrating wood at high rotational speed.

This machine can scan books fully automatically, with no human intervention required.

This casting machine is used in dental laboratories to make dentures. Dentures are made with it.

The precise positioning for clean cuts was important here, as well as the fact that the entire system is maintenance-free.

This gripper takes packaging units from a sealing machine, turn each unit by 90 degrees and arranges them in cartons.

Since water is used, the linear guide must be able to work dependably under water.

This newly developed induction centrifuge melts alloys for dental prostheses.

By using iglidur® W300 plain bearings, reliability can be increased. The previously used ball bearings had to be oiled regularly, which is not the case with iglidur® bearings.

This camera dolly is very quiet and easy to adjust. Thereby it allows many variations of movement.

The rapid and hygienic cleaning of the machine was an important factor.

To achieve the best flying conditions, all components must be lightweight and at the same time as durable as possible.

The special device needed to be as economical as possible in its construction, and the individual components as maintenance-free and durable as possible.

Maximum care must be taken with hygiene wherever foodstuffs are handled.

The exact positioning is important here, which is ensured by the combination of several igus® products.

A low-cost linear plain bearing with a long service life was required, which can compensate alignment faults and is as light as possible.

This machine removes medications from the original packaging and re-packages them in smaller doses.

A DryLin® T linear guide system is used in this medical body scanner.

This pagepulltester is a high-precision measuring instrument for the bookbinding industry.

The trains belonging to this particular model train fan can be driven automatically from the shelf onto the track.

This packing robot even stacks baked goods in boxes. It has a double-headed gripper system.

The manus® contribution submitted here is the new development of a patient lift for ambulances for transporting patients who are able to sit in the vehicle.

This frame construction allows the user to move the clamped tools, such as welding or milling equipment, along three axes, as desired.

Trains are tested for their electro-magnetic compatibility in a shielded hall here.

This device can measure the circumference of car tyres without the vehicle having to be moved.

This contribution to the manus® competition – a robot gripper – is extremely flexible.

This equipment is used to train the dorsal muscles. In order to use it comfortably, the base must be adjustable.

Here, sanitary elements in the bathroom unit are installed with igus® products.

The cables that connect the tractor and semi-trailer must be flexible to compensate for the different lengths of trailers.

The cutting wire is moved along the vertical axis by two DryLin® ZLW toothed belt shafts.

The door, which is about 3 metres high and 1.7 metres wide, is supported by a DryLin® W linear guide. The good gliding properties allow the door to be moved without any problems.

All igus® products used are maintenance- free, giving the machine a long service-life.

This cutting mechanism is used in the beverage industry. Several igus® products were used here.

The challenge was to find a linear guide that can work reliably and quickly under these tough conditions.

This smart application creates more stowage space under the bed.

Here a DryLin® T linear guide is used in a high-performance screen printing machine.

Previously, metal bearings and linear guides were used, which rusted quickly and therefore required frequent maintenance.

This motor is to drive deep-sea robots even at 6,000 metres under the sea.

Gold Award at manus® 2011: Machine for frying Spanish omelettes of Carmelo Lagunas Escudero, Spain

This equipment is used in the food industry. The baked goods are separated on these chains.

This electrically adjustable examination table was also submitted to the manus® contest.

This machine sells bottles of high-quality olive oil. Three movement axes are required to move the bottles from their fixture to the outlet.

This equipment can package various industrial products, with any materials.

The patented machine is an all-rounder when it comes to packing. It can print parcels in a single step and seal them with printed adhesive tape.

the armrests of this chair are adjustable, to accommodate the needs of the individual user.

Are more guests coming than you expected? That‘s no problem with this dining table, because its width can be adjusted to exactly the width you need.

A DryLin® T-linear guide is used for adjustment. This easily copes with the cycle rate of 80 cycles per minute.

Any movement that is to be performed here must be lubrication-free, executed free of wear and, if wear does occur, it must be free of heavy metals, etc., that could give distorted results in the chemical analysis.

The DryLin® W linear guide used as a double rail more than four metres long, making adjustment of the console easy.

Prototype of a gripper that is to be used to stack and move washing automatically in laundries.

Since the tank is filled with salt water, the components used may not be susceptible to corrosion.

At a speed of more than 350 kilometres per hour, these trains will be racing through China as of 2012, connecting Beijing and Shanghai.

High mileage in continuous operation: DryLin® T in a filling system in the food industry.

Ball bearings were used earlier in this parting unit. They completely came apart after just 6 months.

DryLin® R in a facility for the production of aluminum cartridges.

A stop dog system based on the DryLin® W linear guide has been used here for the accurate drilling of glass.

In this baking and conveyor unit, DryLin® T and DryLin® N flat guides are used.

In this testing station, the eddy current crack detection of components for the automotive industry is conducted with the application of DryLin® T.

Maintenance-free guide and bearing in seat and footrests on a fitness equipment.

DryLin® trapezoidal leadscrew nut in a sheet metal forming machine.

DryLin® W for positioning of films in a blister machine.

DryLin® N 40 carriage is used in this closed-loop guide system.

DryLin® linear guide in EURO-C welding tongs for the automotive industry.

Plastic instead of recirculating ball bearings - DryLin® linear guides for machine deburring

Maintenance-free polymer bearings in mobile and stationary saw mills.

DryLin® linear guide systems provide for compact and thereby highly flexible handling devices.

DryLin® plastic plain bearings in an inspection device for offshore drilling riser

Lower wear and more cost effective by converting to DryLin®: so far the system has run without failures.

Application of DryLin® W for the guidance of a conveyor chain for goods.

Application of DryLin® R linear plain bearings for a filling shoe mechanism of a compaction unit.

DryLin® SLW - With reverse spindle in the glass industry for separation of bottles.

DryLin® W in adjusting unit for a glass cutting machine.

Application of the DryLin® spindle lift table in the encoding machine for the height adjustment while changing the encoding material.

DryLin® T in inspection optics for trouble-free examination of concealed solder joints in components.

DryLin® T linear guides of a pneumatic opener mounted on one side for envelopes.

An engraving machine with igus® products, as final project work after four years of advanced education in automation technology.

DryLin® trapezoidal leadscrew nuts and iglidur® high-performance polymer in two-component blending station.

For the perfect cut. DryLin® T in a machining center in the furniture industry.

The positioning of milling heads is done with DryLin® SHT linear slide table in this plant which manufactures aluminum window frames.

The eraser robot of the Hans Böckler-Schule at the Berufskolleg Münster combines technology with cultural history.

For extremely high strengths: DryLin® T linear guide in a tube-bending machine.

The DryLin® N flat guide in a special design provides for the adjustment of spotlights.

Application of DryLin® high-temperature bearings in bag forming, filling and sealing machine for the sealing bar bearing

Application of DryLin® T for adjustment of the pressing roller and the compensation of the imbalance of the grinding tools.

DryLin® high temperature bearings are used in the tool guide system of this forming, filling and sealing machine.

Automotive industry: flexible linear sliding system for automatic welding cap changer.

DryLin® in a champagne bottle

sealing machine in the filling technology.

DryLin® guide systems in a die head for small size tiles work without problems despite dusty and cramped working conditions.

The removal unit is moved along the X-Y axis using the space-saving and cost-saving DryLin® N flat guide.

Even extremely low oil mist could lead to the loss of data - therefore the dry-operating DryLin® N flat guide system was used.

For extremely varied format adjustments: DryLin® SHT spindle lift table.

DryLin® SHT spindle lift table for a precise positioning of the tools in X-Y-Z direction.

Application of DryLin® R for the guidance of the cutting table

DryLin® - Application in the food technology due to the freedom from lubricants.

This application uses DryLin® T linear guide system to steer gripping plates.

Smooth and silent operation due to DryLin® in the doors of the machine tool.

The toothed belt unit with the DryLin® N guide system is suited for highly dynamic applications.

Besides the grease and lubricant-free operation, the silent and smooth operation of the DryLin® linear guide system were decisive for using this system in this designer lamp.

Lubricant-free DryLin® W linear guide systems in a polishing machine for aluminium rims ensure a long service life.

Stop carriage runs smoothly due to wear-resistant high-performance polymers.

Maintenance-free plastic bearing defy all outer influences and provides for the required service life.

Chemical-resistant and corrosion-free: maintenance-free polymer plain bearings in catering kitchen appliances.

Wind, sand and sun: Plastic plain bearing for solar technology

Maintenance-free guide and bearing in arm and leg rest on the dialysis chair.

Precise and durable - Polymer bearings for novel leather splitting machine.

Sought by Mr. Clean - The lubricant-free bearing system is highly recommended for the food and hygiene industry.

Quick, straight, precise: this is how the requirements in sheet metal machining can be summarized. Sophisticated straightening technology makes all this possible.

Maximum precision in color application, thanks to DryLin®.

Saves costs and better

No lubricants in food sector

Less production complexity

Stable and safe

Rust-free and temperature-resistant

Resistant against chemicals and dirt

Effective with little installation space

Flat and durable

Over 170,000 Euro of benefits were able to be achieved by using polymer plain bearings

The bearings reliably transmit the high radial centering forces with low friction and free of stick-slip and minimize the arm system's friction through their integrated start-up.

This novel insertion head (pick & place) for circuit board machine uses DryLin® liners.

DryLin®-supported aluminum shafts with carriage in the set head for small format tiles.

Buzz saw with essentially improved operating feature by the application of DryLin® linear plain bearings.

The problem of the design was in the limited installation space by the combination of two movements independent of each other and the high mechanical stressing.

The redevelopment of a gripper using igus® guide elements resulted in a very thin, rugged and lubricant-free gripper tool that is right now not available in the market.

In this application as well, glide pads made of polymer contribute toward the enhancement of the technical performance and an increase in the degree of automation.

Concrete cutting machine in extremely heavy-duty operation since three years free of maintenance.

In this tool presetting device, DryLin® guide carriages made of iglidur® J200 are used as measuring carriages. They contribute toward the attainment of a precision and repeat accuracy of +/- 0.1 mm in the application.

Due to the low friction in the use of roller bearings, a complex counter force or gripping mechanism is necessary.

Reduction of maintenance rate through polymer plain bearings in seat cover testing machine.

Flat-screen TVs are increasingly mounted on walls. But previously pictures or paintings often hung at this place. Art over TV combines both.

The igus® potentials enable a precise guidance and the maximum gripper speed in both directions "X" and "Y".

The backrest adjustment is implemented with DryLin® products, the headrests are mounted on the backrest with plastic plain bearings made of iglidur® G.

A novel external load system for helicopters required a low weight, high reliability with simultaneous weather resistance and freedom from maintenance.

In the redesigning of the table guidance, the focus was on a ready-to-install, cost-efficient, durable and lubricant-free bearing and guide.

Rotary indexing table for the manufacture of plastic products: igus® guiding systems and energy chains contribute to the problem solution.

Toothbrush testing machine runs with exceptionally low noise by the application of polymer plain bearings.

The employed liner also compensates for a minor misalignment in the axles. The most important feature is the fat-free and chemical resistant version.

Since the switch to DryLin® W, the system runs without any problem and without a stoppage.

Linear actuator with toothed belt drive: All disadvantages were eliminated by the DryLin® WQ guide system.

The application of Drylin® linear housings and iglidur® G plain bearings enable the centering pin to have a clean and easy drive up.

Besides, there were substantial quality limitations with regard to the large clearance in the ball guide. With the igus® low profile guide system, this problem was ideally solved at a low price.

Conventional guide systems break down as no oil or fat whatsoever should enter the dipping bath.

Sought for was a linear guide system for a load cell with light operation, leeway and flat design.

Plain, spherical and linear bearings made of plastic help to improve mobility and the quality of life

In the case of this industrial robot, a rigid pipe between the 3rd and 6th axis wasreplaced by a multidimensional, flexible Triflex® R energy chain®.

Basketball shooting device for wheelchairs: Due to igus® products only a little energy is lost through friction, and there is only a minimal angular shift when the shaft accelerates vertically.

The plastic bearings allowed the design department to fulfill the specifications for designing the input/output port.

Unloading robot in industry: linear bearings enable very quiet running and are totally maintenance-free.

Replacement of solution with lubricants in fastening device to secure aluminium sliding windows.

Reliable continuous operation in air cushion table on industrial feed.

Machine to carry out a non-invasive treatment of complaints on sole of foot fascias works with igus® linear plain bearings.

The new press feeding device needed more space for the new loader.

An automatic product feed takes products to a blister sealing machine.

DryLin® N provides free travel path and guarantees the necessary gap.

DryLin® copes with long distances and offers a high cost reduction.

The bearings from igus® were decided because they are maintenance-free and cost-effective and absolutely simple to handle.

Application of a high-value spindle lift table with steep-threaded spindle, linear guide systems and igubal® spherical bearings.

The aim of the concept is to demonstrate to the students how to handle a programmable logic controller (abbreviation: PLC) in an attractive way.

Despite the particularly very high temperatures (up to 180°C during baking out of the gadget), the igus® plain bearings provide for the necessary flexibility and simultaneous precision.

iglidur® polymer bearings / drylin® linear slide bearings in center armrest

For the equipment made for the film "Chrysalis", only high quality materials were used.

Energy chains, fully assembled with cables and connectors, are delivered ready for mounting (ReadyChain®) and can be installed immediately. In this way the electrical installation time has been halved.

As the air in the machinery is very dusty, no lubricants may be used in the production process.

Using DryLin® T linear guide and iglidur® PRT slewing ring bearings, the movement under the press and the pivoting of the parts to be assembled is mastered.

When it comes to designing customer-specific folding box gluing machines, special machine constructor Bernhardt Maschinenbau relies on lubricant and maintenance-free linear plain bearings.

On these horizontal forming, filling and sealing machines, the total freedom from maintenance over the machines' entire life cycle was particularly important for the customer.

Lightweight, robust and do not require polymer bearings are installed in machine tools and machining centres across a large range of industries.

While designing the sliding sunshade, much emphasis was placed upon a dirt- and weather-resistant bearing and guidance.

In this application, the enormous cost advantage over conventional roller guides was especially important.

In this safety door adjustment application in a washing plant, a DryLin® W linear guide with integrated rollers was chosen.