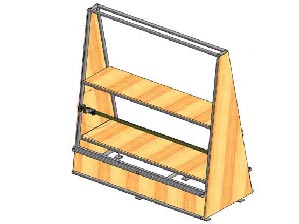

Slide fastening track

The fastening device secures aluminium sliding windows, whilst the sliding tracks click in at the right place. The linear plain bearings had to offer a low friction coefficient and enable different sizes of windows to be held in a fastening device whilst the sliders are fastened. This action is repeated hundreds of times a day. The replaced solution used a tube as a crosslink with another tube with a bigger diameter but shorter in length, which was used as a glider. The tubes were polished and coated with grease to reduce the friction. The lubrication had to be redone every week and then also got onto the windows, which then had to be cleaned before despatch. These were also heavy and awkward to maneuver. Both the DryLin® linear guide systems and a ball bearing system were tested. DryLin® W was the clear choice with regard to the requirements of pressure, speed, cycle times and environmental conditions. DryLin® W costs less than a ball bearing system and is easier to install.