Water turbine for power generation

Cost-saving and efficient

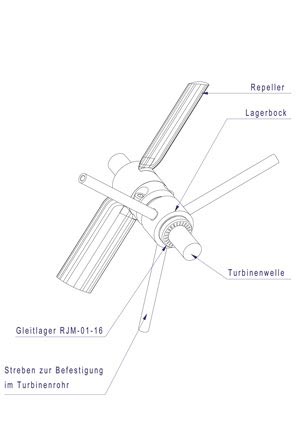

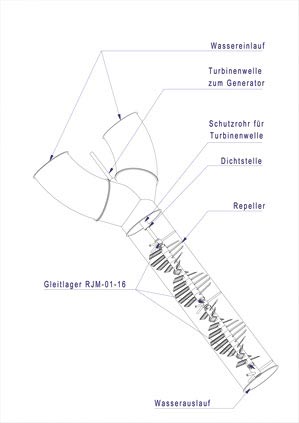

On this new turbine, energy is generated by several repellers arranged in a row. The use of conventional roller bearings on the turbine shaft and the bearing ring seals required for this caused high manufacturing costs, friction loss, susceptibility to repairs and high maintenance costs. Using DryLin® plain bearings enabled four critically necessary sealing points to be reduced to a single uncritical one, the smooth running of the turbine was increased and the bearing points are resistant to dirt.

Georg Heindlmeier, smartkraft erneuerbare Energie GmbH, Ebersberg

More on applied products here

Further interesting applications from extremely diverse areas can be found here.

Go to manus® contest