Over 170,000 Euro of benefits

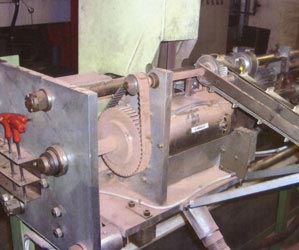

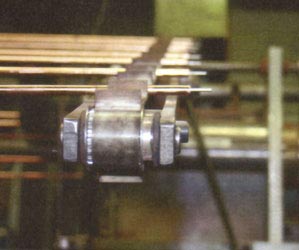

Bronze manus® 2009Tubular heating element belt grinding machine

In this application, tubular heating elements are subject to dry grinding. The bearings in this application must be robust and resistant to dirt, as they are constantly in contact with the copper or corundum grinding dust. Although an extractor also operates at the grinding points, complete dust extraction is not possible.

Thanks to the use of DryLin® R linear plain bearings and flange bearings made of iglidur® G, the dust is no longer a burden, as it cannot stick to the lubricant-free bearings. Even more important, however, is the bearings' abrasion resistance, as the abrasive particles from the grinding process are always present on the bearing point. Not many materials can survive that. In addition, there was an improvement in the quality of the heating elements produced in the form of even grinding without flat spots, which occur when grinding by hand, which convinced the user about the plain bearings: “From 2000 to 2008 there has been a benefit to our company of 170,832.00 Euro,” says Gerhard Klemm, Döbeln Elektrowärme GmbH.

Winner of manus® 2009

manus® Gold: Low wear and resilient

Low wear and resilient by using polymer plain bearings.

manus® Silver: Secure under high forces

Secure under high forces: maintenance-free plain bearings made of iglidur® Z can withstand extreme loads.