Wafers for the world

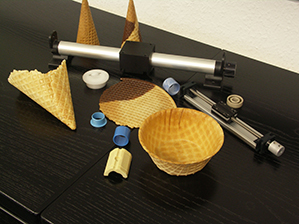

Sturdy lead screw linear system for extracting paper ice-cream cones.

Simple, sturdy and efficient: These are the characteristics of this lubricant-free linear system, which is used in an industrial wafer baking system. It demonstrates its effectiveness in the confectionery field when separating and feeding paper ice-cream cones. Thereby on the one hand very high cycle numbers are run, and on the other, adverse environmental conditions affect all components. Tribo-optimised high-performance polymers of igus® GmbH provide stable conditions on the long-term, so that the operating performance of the plant constantly increases.

Simple, sturdy and efficient: These are the characteristics of this lubricant-free linear system, which is used in an industrial wafer baking system. It demonstrates its effectiveness in the confectionery field when separating and feeding paper ice-cream cones. Thereby on the one hand very high cycle numbers are run, and on the other, adverse environmental conditions affect all components. Tribo-optimised high-performance polymers of igus® GmbH provide stable conditions on the long-term, so that the operating performance of the plant constantly increases.

"Our wafer baking machines are characterised by very high capacity and flexibility after the retrofit," says Dipl.-Ing. Dieter Kempaß, General Manager and Chief Technical Officer of the company Walterwerk Kiel GmbH & Co. KG. "They are used worldwide. " Heat, fumes, wafer dust and moisture pose extreme demands on the machine elements that must still function properly in the long run. Only thus can smooth service life and minimum maintenance intervals be guaranteed.

Intensive polymer research

For many years the special machine manufacturer has been using lubricant-free plain bearing systems of the igus® GmbH in its modular baking systems. It is maintenance free, cost effective and has versatile use. The challenges of the customer have always continued to rise over time. In their facilities for the fully automatic production of wafers, solutions are scarcely installed off the shelf, but are specially customised ones that have been found to some extent even in the standard product range of the tribo-polymer specialists.

Christian Wille, technical sales consultant of igus® adds: "The technical properties of the polymer materials have improved significantly since their inception around 30 years ago. We have carried out extensive material research in our own test laboratory in recent decades, developing more and more applications, which would have been unthinkable a few years ago. “

Plain bearings made of high-performance plastics for the food and packaging environment are FDA-compliant, depending on the choice of material. Product contamination by an additional regular lubrication is thereby excluded. Friction and wear have been optimised due to their tribological properties, which has a positive effect on the operating times of the machines. Even the regular cleaning with aggressive media presents no problems.

Endless wafer variety

"The world needs more and more ice cream cones," says Anika Weiß from the marketing department of the specialist machine manufacturer. "We serve a niche market and distinguish ourselves by long-term customer relationships. " The capacity of baking systems is constantly increasing. Depending on the machine size, from 3,000 to 19,000 standard wafers are made per hour. "That is, more than five wafers per second", clarifies the marketing specialist.

Rolled, wrapped, deep drawn, stamped, smoothed, cross cut, folded, savoury or sweet wafers, snack wafers, rolls, ice cream cones, wafer cups, mini wafers: The process and production capabilities of the baking equipment from northern Germany are manifold. The baking process of a standard wafer for the industrial ice cream production is always the same. It is baked in the flat state in the oven, then supplied to a wrapping station and rolled up while warm. Then the further transport to the cooling tower takes place via a link chain conveyor belt before the wafer is provided with a paper bag in the processing area. Only then does the filling with ice cream takes place in a subsequent process. In order to meet the high performance requirements, the process takes place in several paths. It must be guaranteed that only one bag is fed, or else this would cause problems when filling. If a customer has different paper bag sizes, the system must be readjusted again and again to the conditions on the site.

Reproducible processes

A requirement criterion for the linear unit is the reproducibility of the stripping process. The system usually operates seven days a week in three shifts. It stops only for a few hours for the cleaning. The outer local conditions are demanding. Ambient temperatures of around 50°C prevail at times. In addition there is the pervasive wafer dust. It is tacky due to the sugar content and the residual moisture. There are also customers who add salt to the product to enhance flavour. Both salt and sugar are extremely abrasive.

A series of tribo-optimised plain bearings are used in the baking equipment. They meet the high requirements free of lubricants.

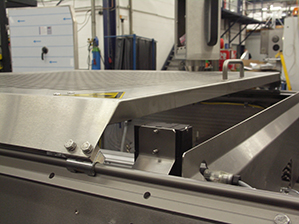

Alignment and format adjustment of a prism beam in the paper ice-cream cone stripping station.

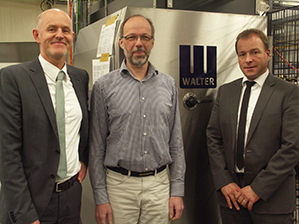

Dieter Kempaß (Walterwerk Kiel GmbH & Co. KG) between Christian Wille (right) and Lars Braun (both: igus® GmbH).

Position adjustment of the batter-spraying pipe with a clearance-adjustable lead screw linear table.

Safety hood adjustment with maintenance-free hybrid bearings for the lowest adjusting forces.

Baking systems for industrial ice cream wafers are also often equipped with gluing devices in order to glue the bag and wafer additionally with a sugar solution. They may splash and should still not affect the separation process.

"We tested different approaches and finally chose a simple but reliable system solution that can be adjusted manually by the user," says Kempaß. In a wafer baking system that is shipped to Korea, two parallel systems must be adjusted simultaneously over a length of about one metre. The two lead screws are connected via a helical bevel gear on one side. Due to the low loads, a shaft structure for support could be dispensed with. The guide pipe made of aluminium guides the stainless steel lead screw inside. The combination of materials withstands the harsh environmental conditions. There are also a position indicator and a hand wheel. The whole system is maintenance-free. And due to the absence of lubrication, the contact with food is safe.

Universal high-performance polymer

Since the lead screw is guided in the hollow profile, the iglidur® material at this point need not be food safe. Its feature is the significantly reduced moisture absorption, which is an advantage mainly for use in damp environment. It is also distinguished by economy and very high stability.

In the stripping station, the main issue is the format adjustment, especially when it comes to the long term stability. Whether formats need to be adjusted is decided by the customer. For large manufacturers of ice cream or wafers, they do not change as a rule. Smaller suppliers have to adjust the formats of the bag size. "This is, however, in the scale of a maximum of once a day," reveals the technical manager and authorised representative. A change in the size is usually in the millimetre range. It is controlled by the position indicator. The fully assembled complete solution from a single source is the focus for Walterwerk Kiel.

System solution in focus

The special machine manufacturer has procured the complete lead screw linear unit as an assembled system. Thus it is not only the technical parameters, which are fully designed for on-site requirements, that are ideal but it also makes excellent business sense. "We draw a complete solution from our construction kit and responsibly deliver the entire system from a single source," says Wille. Thus, the special machine manufacturer is on the safe side in all areas.

Basically, the cooperation between the two companies is good. As a first step, the various online configurators are usually used. However, the requirements due to heat, moisture and exhaust gases in the baking equipment are so high that the actual technical layout takes place on site. Furthermore if the standard dimensions do not fit, prototype parts are manufactured in a manageable time frame. "We are very satisfied with the technical skills and reaction times," says Kempaß conclusively.

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!