Wind, sand and sun: Plastic plain bearings for solar technology

Conergy uses igus® components in the new photovoltaic tracking systemAlways the correct angle to the sun: This is guaranteed for the SolarOptimus tracking systems at the photovoltaic plants of the Conergy AG. The two-axle drive systems controlled by an astronomical algorithm increase the yield of environment-friendly energy by around 30%. For the maintenance-free operation of the plants for long periods under extreme weather conditions, Conergy decided on components from igus® for both the bushings and rod end bearings and linear units.

In the realm of wind energy and solar technology, Germany takes a top spot in machine and plant construction. This position is traced back to dynamic market participants like the Conergy AG in particular: The company, first established as a solar system integrator in Hamburg in 1996, today offers a wide regenerative range of products for the generation of power, heat or cooling. Listed in the stock exchange and in the TechDAX since March 2005, the Conergy AG increased its turnover by, believe it or not,1830%. With it, Conergy is among the strongest growing technological companies in Germany.

Conergy's success is attributed on the one hand to its offering of complete system solutions worldwide for the generation of regenerative energy (wind, solar and biomass) including project management, servicing and financing. On the other hand, the impressive growth is due to the company's developing and manufacturing of its own products. Thus one of the most modern manufacturing plants in Europe for the production of fully integrated solar wafers, cells and modules is emerging at present in Frankfurt/Oder, in which Conergy has invested around € 250 million. When it is completed, around 1000 people will be employed.

Spain: With the SolarOptimus systems, solar power plant operators in sunny regions can increase their yields by more than 30%.

The question "Make or buy?" is very precisely analyzed by Bernd Krabbe, director of the Engineering and Service division of the "Global Technology Team (GTT) Electronics" in the Hamburg headquarters: "We look around in the market and evaluate whether there is any system that is adequate for our high customer requirements. If there is not, we develop our own product. " In the tracking system for photovoltaic plants, the available products obviously do not meet the high requirements, so we recently developed our own product: the "SolarOptimus"

The task of the system is to always ideally position the photovoltaic generators in the direction of the solar incident radiation - an investment that pays off for the operator, because you can increase the energy yield by more than 30% with a two-axis tracking system. In Germany and the neighboring countries, the ideal position of the PV module is detected by brightness sensors - in case of clouding, the sensors always move toward the brightest spot. This might sound as if an astronomical algorithm doesn't function in Germany, but that isn't the case. However, in southern Europe where the sky is often cloudless and very bright, systems which keep the modules always in the ideal angle to the solar radiation using astronomical data are more effective.

The iglidur® bushings are installed in the main axles of the tracking system: They provide low-friction rotary movements even under unfavorable conditions.

This control system is also useful for SolarOptimus, which was specifically developed for radiation-intensive southern regions. Product Manager Philipp Vanicek: "The modules move in two horizontal axles according to an astronomical algorithm. " In the development of the framework system, long life and freedom from maintenance were on focus, because the facilities often work in remote areas without personnel on site. As a result, the developers deliberately avoided complex drive systems and used simple-structured, but high-quality components. This applies for the motors as well as for the bearing positions. Bernd Krabbe, another director of the SolarOptimius development project: "We explained our requirements to several bearings suppliers and requested for solution proposals. " In the process, the frequently very dry locations of the solar plants had to be taken into account; accordingly high was the stressing from sand and fine dust. Added were the extreme temperatures in which the bearings should work flawlessly.

In view of these criteria, the proposed solutions put forward by igus® were the most convincing: All bearing positions of the SolarOptimus are equipped with igus® products. The iglidur® plastic bearings at the main axles of the about 20-meter long framework system provide for low-friction and maintenance-free bearing. The "integrated" solid lubricant of the high-performance polymer moreover gives you the freedom to avoid dirt-attracting lubricants. This is a central requisite for the long service life of the bearing under the given application conditions.

Conergy employs iglidur® G, the "all-rounder" among the numerous iglidur® materials, which is suited for pivoting and rotating movements at low to medium speeds . The insensitivity to dirt is another important property of the iglidur® G bushings.

For the kinematics of the adjustment system, Conergy decided on the DryLin® linear bearings from igus.

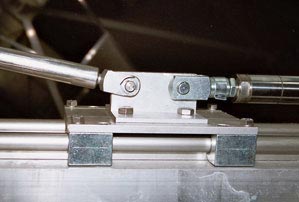

To relieve the drives, the developers at Conergy have provided plain bearings in the kinematics of the adjustment system. Here too the high-performance polymers from igus® are used: The DryLin® linear plain bearings provide for an accurate linear guidance of the axles. The DryLin® W bearing housing made of rugged zinc die casting moves on a stable rail profile; the tribological pairing of hard anodized aluminum (rail) and iglidur® liner (housing) creates the precondition for low-friction operation without "stick/slip" effects. The mounting plate for the support of the moving components was adapted by igus® at the request of the Conergy developers. Sand and dust can do no harm to this linear bearing: They are simply pushed away in the "snow-shovel effect" without impairing the glide properties.

For the coupling bars which interconnect the solar module mounting, Conergy opted for igubal® rod end bearings. These connectors take high loads, have excellent dampening properties and at the same time weigh only a fifth of the weight of conventional metallic bearing housings. But more important for the application in the tracking systems is that the rod end bearings remain maintenance-free even when the environment is stressed by fine dust or abrasive pollutants. There is no danger of fretting or jamming, and the integrated solid lubricants provide for low friction with extreme abrasion resistance.

Side view of a DryLin® W plain bearing in the SolarOptimus tracking system. The mounting plate for the support of the moving components has been specially made for Conergy.

The drive system of the module frame responsible for the North-South orientation applies a force of 6,800 N, while the drive system of the main frame for the East-West tracking, 10,000 N. The speed at maximum 4 mm per second is low, and the drive completes a maximum full rotation per day. Regardless, high demands are posed on the wear resistance, because the ambient conditions stress all the components. Therefore igus® conducted a comprehensive series of tests for Conergy and had thereby flown in very abrasive sand from southern Spain, where the first SolarOptimus systems have been installed in the meantime. The (pleasing) result: The igus® bearings were not replaced during the entire calculative service life of the SolarOptimus even under conditions that were harsher than in real practical operation. This applied not only in terms of sand and dust, but also in terms of the UV-resistance of the plastic, the broad temperature range and the humidity.

Meanwhile the first SolarOptimus systems have proved themselves in practice for many months in southern Spain - and all evidence shows that the calculated extra yield through the astronomically supported tracking has been achieved. Environmentally-friendly energy is generated and supplied to the network by the 800 moving systems in the completed facility at this location. Moreover, Conergy has planned several other projects with a large number of tracking systems. Bernd Krabbe: "We have already sold SolarOptimus systems with a total power of 13 MW. “

Customer-specific "igubal®" rod end bearing as connecting elements for the coupling bars which connect the solar module with the mounting frame.

igus® accompanies this pleasing development task not only as supplier, but also with the customer-specific optimization of the bearing positions. Thus the manufacturing costs are reduced with larger number of units. Given the dynamic development of the Conergy AG, there is no doubt that quantities will increase.