Search for application examples

For years the igus® motto has been "plastics for longer life®". By this we mean the production of innovative plastic products which reduce maintenance work, achieve technical improvements, at the same time as reducing costs and increasing service life, everything delivered immediately from stock.

Some examples:

The E-ChainSystems® today clearly contribute toward reliability, as system downtimes, for example through cable breaks, are reduced to zero.

Cables defy heat, sun, rain and snow

Previously used cables from a competitor had failed; since then the temperature-resistant Chainflex® cables are used; the larger-than-life size LED screen in Dallas functions in any weather.

Rough environment, high speed

Even in particularly aggressive ambient conditions like in this high speed machining center, energy supply systems prove their reliability.

Costs saved, machine

availability increased

As iglidur® plain bearings have a long service life, and in addition need not be lubricated and costs only a fraction compared to conventional bearings, 90% of the costs could be saved.

More than Euro 10,000 saved each year

The previously used bearings were blocked and the shafts used to break. The lubricant-free igubal® flange bearings used instead have been operating since May 2007 without failure. This saved Euro 2,440 in repair costs and Euro 8,400 in machine stoppages each year.

Trouble-free operation instead of shaft destruction

Due to the dirt accumulation in the ball bearings, the balls were blocked and the shafts were destroyed. The concrete cutting machine has now run for over three years entirely free of troubles despite the extremely heavy-duty operation.

Bulkhandling Cranes applications

igus® applications and references with bulkhandling cranes.

Ship unloader

441m travel with E-ChainSystem® in Malaysia: Reduction of tensile strengths by about 75%, E-Chains® with weight up to 2.5 tons.

Sewage treatment plant

Energy chain system instead of cable drum - Smooth operation at the sewage treatment plant since 2000

Concrete pipe cutter

Concrete cutting machine in extremely heavy-duty operation since three years free of maintenance.

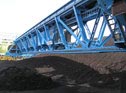

Lignite quarrying

The wagon makes a 180° turn and empties into the coal bunker. The energy chain secures the energy supply of the rotating device.

Coal-fired power plant

Operation in severe dust. The energy chains are employed in trolley and crane, the crane drive arranged in the opposite direction.

Coal-fired power plant

E-ChainSystem® for a coal unloader. Operating since three years without any problem.

Steel works

Extremely difficult conditions: Dirt and dust, heavy filling, long travel and high temperatures. The system functions since 2003.

Heavy fillings

E-Chains® for heavy-duty uses: Guiding of the supply cables of a quenching chamber, which moves toward the linked vacuum ovens.

Mining industry

The E-Chain® is located in the area of the rotating assembly in a bucket-wheel excavator.

Offshore industry

High pressure hydraulic hoses + power cables. Extreme weather environment but this chain delivers and delivers.

Offshore industry

Tube handling plant provides an igus® plastic E-Chain®. E-Chain® ensures high stability and reliability in pipehandling.

Power plants

Safe function despite extreme dirt accumulation: Parallel facility in the waste-to-energy plant

Waste incineration plant

Safe application of E-Chains® in waste incineration plant

Road construction

An asphalt finisher applies hot and cold bitumen mixtures. The E-Chain® supplies the front area of the vehicle and is exposed to extreme dirt.

Steel mills

Temperatures up to 1200°C or lashing blaze from the oven pose high demands on the plant.

Thermal application

igus® roller chain in power plant application: Strong dust, application of the chains in trolley and crane, the crane drive arranged in the opposite direction.

Waste incineration plant

Application of E-Chains® in waste incineration plants: Strong dirt with high metal content and 300,000 t waste every year.

Tunnel construction

Tunnel boring in defined sections with the assistance of an igus® E-ChainSystem®, which guides the essential hose cables section by section.

Composting plant

Heat, abrasive dirt, high atmospheric moisture: These are only some of the ambient conditions in a composting plant.

Sewage treatment plant

The used igus® products prove themselves till today and drastically reduce the maintenance input.

Sewage treatment plant

The existing system with a motor cable drum proved to be not resistant enough in the difficult outdoor environmental conditions, and was replaced by a flizz® system.

Piling and drilling rigs

The driven boring machine produces extremevibrations and heavy soiling duringthe work process.

Dismantling tool

During the removal of a nuclear power plant, 14 metre-high steel tanks are milled into small metal chips. At the same time, a milling cutter, which is used as a dismantling tool, must be inserted precisely into the tank from above.

Excavator

The plain bearings run without lubrication and without significant wear and tear

in the very harsh environmental conditions of construction machinery.

Service life clearly enhanced

This application shows that the use of Chainflex® control cables significantly reduces the failure rate of the machine in the concrete factory.

Maintenance-free operation for 8 years

The energy chain employed in 2000 runs smoothly.

The longest travel with plastic energy chain

The complete length of the E-Chain®'s travel at 615m clearly exceeds the previous record holder at the Singapore harbor.

Special machine construction

Energy supply systems demonstrate their reliability even in particularly aggressive environmental conditions in special-purpose machinery construction.

Sand blasting machine

Sandblasting machine for treating the surface of wind power tower sections.

Goliath Cranes applications

igus® applications and references with Goliath Cranes.

Heavy Duty applications

Examples for the use of igus® e-chainsystems® in cranes.

Inlet control device

The plain bearings must withstand static radial loads of 25 N/mm² at temperatures of 170°C - 200°C.

Indoor and outdoor cranes

Outdoor cranes must withstand severe weather conditions. Even indoor cranes work under ever-changing humidity conditions together with very high temperatures.

Bucket wheel reclaimer

This bucket wheel reclaimer also has to be equipped with a assembling of +/-180° which can move in a circle. The E-Chains® have to acced this movement.

Crane in metal processing

With this indoor crane application, igus® E-Chains® can really show off their strengths.

Excavator

Difficult environmental conditions such as dirt, lubricants, steel wool and temperatures between -30° and +50°C in particular make maximum demands on energy chains.

Bucket wheel reclaimer

This bucket wheel reclaimer, which is used in a port, also has to be equipped with an energy supply that can cope with a circular movement of 360°.

Movable melting furnace

The special requirement with this furnace system was the movement of the filled furnace weighing a total of 45 tonnes.

Patient lift

The manus® contribution submitted here is the new development of a patient lift for ambulances for transporting patients who are able to sit in the vehicle.

Sewage treatment plant

The flizz® system energy chain solution in the longitudinal scraper bridge and sand trap in a wastewater treatment plant of the Kempten sewage board.

Bucket wheel reclaimer

This bucket wheel reclaimer also has to be equipped with a assembling of +/-180° which can move in a circle. The E-Chains® have to acced this movement.

Rocket launch site

The igus® products used are designed for mobile applications in such a way that it features a long life and functions absolutely reliably.

Coal silo

Lower weight and space requirements than alternative solutions for conveying coal.

Sludge processing

plant

World's biggest polymer energy chain: Being many times lighter than comparable steel chains it easily moves over 100 kg of filling per meter.

Sample collector

This machine automatically takes samples from a coal conveyor belt.

Paddle-wheel equipment

This paddle-wheel stacker is used for the intermediate storage of bauxite outdoors and can be moved linearly over a distance of around 330 metres horizontally

Working platform

This working platform is usually used for underground mining. Up to now, hoses and cables hung loosely from it, which meant they could get caught easily and become damaged.

Handling facility

Cole is transported in this handling facility over a distance of 200 meters.

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!