“Absolute reliability means everything for us”

Special-purpose machine construction: Pre-assembled energy supply systems for a high speed machining centerEnergy supply systems demonstrate their reliability even in particularly aggressive environmental conditions in special-purpose machinery construction. With the added economic constraint of having to produce even more efficiently in order to considerably reduce assembly times, there is no way round pre-assembled energy supply systems any more. If the quality and service are right too, the foundations are laid for long-term cooperation.

“Our core competence lies in rotogravure plates,” explains the Managing Director, Christoph Gschoßmann, of Kaspar Walter GmbH & Co. KG in Krailling near Munich. With around 80 employees, the company offers customized solutions for system-integrated plate production and cylinder processing in rotogravure printing. On its factory premises covering around 10,000 m², galvanizing equipment and machinery for engraving cylinders are designed and produced using state of the technology. A milestone in its history was the installation of the first fully automatic galvanic line in illustration printing in 1978. This provided a decisive contribution in reducing the costs in the manufacture of rotogravure plates. A further expansion came with the introduction in 1988 of the adapterless, fully automatic cylinder production line connected to a cylinder storage facility.

Stephan Bobritz: “The E-Chains® in our machines and equipment come under severe pressure as a rule. “

The logistics company Bauer Logistik Systeme GmbH & Co. KG based in Itzehoe became a sister company in the year 2000. The joint venture entered with Hell Gravure Systems in Kiel finally made Kaspar Walter a system suppler in cylinder production. “We are a typical machinery and equipment manufacturer and provide technical and industrial advice for all the big printing shops. And with our two sister companies, we can finally submit turnkey offers,” says the managing director.

Enormous price pressure

“We depend on reliable component suppliers for our highly complex machinery and equipment,” points out Christoph Gschoßmann. Energy supply systems from igus® have been employed for at least 15 years. They basically come under tremendous strain. Depending on the travel distances, various chain types in open or closed forms are used. Due to the environmental conditions, an ESD version is also used.

The managing director continues: “The price pressure in our industry has now become so great that we have to make the most of further cost saving potential. Pre-assembled energy supply systems play in important role in this respect. We fully exploit their technical and above all economic benefits!”

Oliver Fechner (l), Stephan Bobritz (r): “A pre-assembled energy supply system for our new development – a high speed machining center for turning, grinding and polishing rotogravure cylinders. It sets standards in the market!

The other axes are equipped with energy supply systems. The aim here is to supply the whole mechanical subassembly as a turnkey system over the long term.

Pre-assembled energy supply systems are supplied by the Cologne company under the name “ReadyChain®”. From simple E-ChainSystems® with inlaid Chainflex® cables ranging up to complex systems, they are assembled to customer specifications and delivered on time. Any batch size is possible. “We assume complete responsibility for the system so that the customer can concentrate on its core competence,” says the igus® Product Manager, Michael Offner. “Furthermore, every system is tested thoroughly on our test stands before delivery so that the customer is always on the safe side. “

Adverse environmental conditions

“Our machines and equipment are mostly used in electroplating,” says graduate engineer, Oliver Fechner, responsible for Design & Development, pointing out the usually very unpleasant environmental conditions. “Even when the energy supply system is not directly exposed to aggressive media, it comes into contact for instance with chemicals through the humidity. That is why our machines must be rust-proof on the one hand, whilst the chains need to be extremely robust. On top of that, the stresses are increasing. Our machines in the print shops are in fully automatic use seven days a week around the clock. Reliability is therefore crucial for us. There must not be any cable or chain breaks, but instead the whole system should run maintenance-free as far as possible,” says Oliver Fechner highlighting the main requirements of K. Walter.

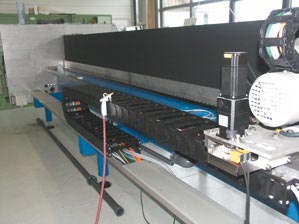

The energy supply system in enclosed form for the movable control panel. It prevents chips or other foreign material from penetrating.

“ReadyChain®” for machining center

“We have been using pre-assembled energy supply systems for over a year on a turning and grinding machine,” says Oliver Fechner. This concerns a high speed finishing center for turning, grinding and polishing rotogravure cylinders, the 'Finishing Center CFM Compact'. The unit can be integrated with automatic production lines. It is used in the package printing sector. “We are setting standards in our industry with this finishing center,” adds Christoph Gschoßmann. Seven energy supply systems in total are used in the small series, of which two are pre-assembled “ReadyChains®”. Six move the axes, one the control cabinet. “For the die carrier, we rely on the ReadyChain® from the start. The speed of the tool shaft is about 9 m/min, the travel distance at about 2.5 m. Due to the positive experiences, we decided as the next step to also equip the movable control panel with the pre-assembled version,” says Oliver Fechner. “And our long-term objective is to have all six axes delivered as a complete mechanical subassembly to install on the finishing center ready for use. ” The energy supply system from Series 39 is used. This design represents the standard on chains of this size. The series offers the best compromise between ease of assembly, stability and costs for nearly all application areas. It is distinguished among other things by a dual stop system, is corrosion resistant and suitable for tight installation conditions. Even with long travel distances, a high unsupported length is achieved with this chain. “The enclosed chain design is used incidentally on the control panel, in order to protect the cables from chips, for example,” adds the mechanical engineer, Stephan Bobritz. “All other energy supply systems on the other hand are protected in the machine housing!” The pre-assembled energy supply system is made up of at least 150 individual parts: cable types, hoses, connectors, contacts, inscriptions. Among others, “Chainflex®” cables prove their all-round ability as highly bending-resistant control, encoder and converter cables. “As this finishing center involves a small series, we were able to produce the configuration with a reasonable outlay in this case. From our point of view now sells itself. The effort involved in ordering is much less for our purchase department. We only have to specify the order number now and get the pre-assembled energy supply system delivered on time for installation,” says Stephan Bobritz pointing out the economic benefits.

Energy supply system with long travel

Lower vertical range of manufacture

“As a supplier to the printing industry, we are subject to its severe fluctuations,” explains the managing director in closing. “We will only have long-term success with our machinery and equipment if we survive among the competition. ” Assembly and hence delivery times are reducing with the pre-assembled energy supply systems; purchasing expenses and storage costs have gone down considerably. The company is able to react flexibly to order fluctuations. "Ten years ago we still had a much higher degree of vertical manufacturing integration. This is no longer appropriate. Nowadays we look for partners in the market who are specialists in their sector like igus. We just buy the additional parts and assemble them all. I could imagine that sooner or later our whole product range will be equipped with pre-assembled energy supply system,” says Christoph Gschoßmann looking to the future. “Our experiences so far have been very good in any case!”