The base polymer is crucial for the wear resistance.

Discover igus® dry-tech® solutions

Worldwide, more than 50% of lubricants are discharged into the environment.

(State of Baden-Württemberg Environmental Protection Agency)

At a world-wide lubricant consumption of 37.3 million tonnes annually, this results in more than 18 million tonnes of uncontrolled discharge into the environment

RWTH Aachen)

Malfunctions due to deficient lubrication cause USD 240 billion in damage in the US alone

(MIT), Institut für Technologie Massachusetts

The right plain bearing...

... for every application

... made of tribopolymer

... lubrication-free

... tested and predictable

... dirt-resistant and corrosion-free

... leight weight and silent

... Reduce costs and increase service life

... extensive standard product range and individual design

... from stock in 24 hours

What is the dry-tech® sample box?

The igus® dry-tech® sample box

How does this function?

Fibers and filling materials reinforce the bearing to take high forces or edge loads.

Finally the solid lubricants automatically lubricate the bearings and prevent friction in the system.

Their product advantages are their technical properties

Technical properties

Cost saving given by elimination of maintenance work

Avoidance of lubricants

no central lubrication system required

No downtimes

igus® tested

igus® operates the largest laboratories of its industries with over 200 test stands for varied types of application and loading scenarios.

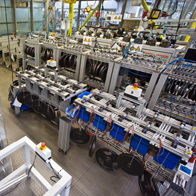

Application examples

The iglidur® plain bearing application spectrum ranges from applications in packaging and medical technology, which avoid lubricants for hygiene reasons, to highly contaminated applications, e.g. in agricultural engineering.

Technical properties

igus® develops special plastics - tribopolymers - that are optimised for various applications with respect to wear and therefore the service life.

Application example

in continuous operation

"Bearing materials marked by special properties such as low coefficients of friction in dry operation, resistance to chemicals and low humidity absorption in equal measure are best suited for the application in high-tech beverages bottling plants. ”

Bernfried Götz, KHS AG, Monzingen

Technical properties

iglidur® plain bearings are very robust in contaminated environments, primarily because lubricants are avoided. - Dirt particles do not adhere to a lubricant coating on the shaft or the bearing location. - Dirt can even be partially embedded. In place of a soft and thin gliding surface that can easily be damaged by abrasive particles, there is a homogeneous material structure across the entire wall thickness.

igus® tested

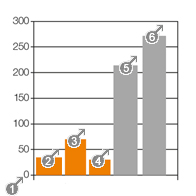

1. Wear rate [µm/km]

2. iglidur® Q

3. iglidur® G

4. iglidur® Z

5. Brass with initial lubrication

6. Rolled metal with gliding layer

A host of tests in the igus® tribo lab show what has been confirmed in field use in industries such as agricultural engineering, wood processing, construction machinery, etc.: iglidur® plastic plain bearings are rugged and have a long service life even under the most adverse conditions, while also protecting the shaft.

Application example

The external demands on custom bearings developed by igus® when used on the job during Summer are extremely high. "These primarily involve radial forces", explains the design engineering manager at FELLA-Werke GmbH, Grad. Eng. (FH) Bernhard Kohl. In order to protect plain bearings against damage from these crash events, they must be impact-resistant and very robust. “ Then there is dust and dirt plus finally the high pressure washing. “Rough conditions and long service lives with possible corrosion on the steel parts place very high demands on the plastic bearings,” says Bernhard Kohl.

Technical properties

The dry-running properties of iglidur® plain bearings are not only advantageous in contaminated environments. The absence of lubrication is also an important criterion in applications with elevated requirements for hygiene and purity.

igus® tested

All standard tests at the igus® tribo lab are conducted without lubricants. Only special customer-specific tests are conducted with contact to media - incl. lubricants when appropriate. This approach allows us to optimise our materials for dry running conditions, and we therefore know in detail what service life can be expected.

Application example

Now the bearings of the W300 type and iglidur® Q are seated in all bearing points of the artificial knee joint. The bearings require no maintenance, operate without clearance and exhibit only minimal wear. Moreover, they should run free of noise, dampen impacts and have a good price/performance ratio. Bearings of type W300 and iglidur® Q are now seated in all bearing locations of the artificial knee joint.

Technical properties

All iglidur® plastic plain bearings are by their nature corrosion-free. There are also special purpose materials, which can be used against caustic solutions, acids, cleaning agents, etc., and, due to their media resistance, can be used even under the most adverse conditions. - The product range also has special purpose materials for permanent use in submerged conditions.

igus® tested

Submerged testing in the igus® tribolab has resulted in iglidur® materials that play to their strengths primarily in these specialised applications. - In this case, the medium is not necessarily always water; other liquid media are also used.

Application example

The enormous increase in service life of the roller chain is due to its special joint structure. A high-performance polymer bearing from igus® was integrated in a stainless steel carrier bushing, "which significantly enhanced the tribology of the chain joint." According to the customer's statement, "the plastic plain bearings raise the bar with extremely high wear resistance, a low friction value, high compressive strength, and chemical resistance." “

Technical properties

Weight reduction plays an important role in a host of applications, which plastic bearings are ideally equipped to address. - This could involve the need to attain an increase in energy efficiency, or to increase cycle rates and speeds.

igus® tested

Due to their low material density, plastic plain bearings have significant advantages compared to metallic alternatives with respect to the topic of weight reduction.

Technical properties

Quiet operation is primarily of significance where people are directly affected. Comfort and well-being are materially impacted by background noise.

igus® tested

The igus® tribo lab is all ears when it comes to the topic of noise profile. - After all, what use is an unlubricated plain bearings with a long service life when it screeches and grinds?

Application example

"A gliding body was to be found that should fulfill the following functions: It should glide on drawn aluminum profile (column), the material must be abrasion resistant, the gliding movement should be free of noise, the gliding body cannot leave behind traces and it should possess a ten-year service life. After several rejected solution proposals, only the material from igus® remains. It began functioning at first go, and five years have passed since. ”

Hanna Tielebier, Carl Zeiss AG, Jena

The right iglidur® material

Expansive wear data from more than 15,000 tests each year under various conditions help to identify the ideal material for any application.

Determine your ideal bearing material - on your own, or with our assistance. Using the iglidur® product finder and the iglidur® service life calculator.

iglidur® product overview

iglidur® product overview

iglidur: Large range of Bushing & Accessories from igus®

Order from stock

All-rounder

The endurance runner

High temperatures

High media resistance

Food contact

Special applications

more plain bearing designs

Bar stock made of engineering plastics: iglidur® in one piece

Bar stock made of engineering plastics: iglidur® in one piece

Bar stock made of engineering plastics - iglidur® in one piece for the free designing of your application.

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!