iglidur® Frequently Asked Questions

The iglidur® plain bearings are designed in such a way that they can be pressed into a housing (with an H7 tolerance) with the nominal size of the bearing outer diameter and are then secured by the press-fit. This is achieved by the so-called press-in excess, i.e. the outside diameter of the bearing is, depending on the nominal size, about 0.1 to 0.25 mm larger than the housing in the non-pressed state. The inner diameter also reaches its final dimensions and tolerances only when pressed in.

The variety of iglidur® materials developed from the obligation to meet a variety of customer requirements over the past nearly three decades. The development of a good bearing material often has something to do with squaring the circle. If you optimize in a particular direction, this is done mostly at the expense of another feature. – The vast majority of applications can be technically covered by the five standard materials - iglidur® G, J, X, W300 and M250.

But if it has to do with very special or sophisticated applications, or the exhaustion of the last technical reserves, or concerns the last price/performance optimization for high volume production, the other iglidur® materials become increasingly important. In the last few years, the application limits of the dry-running plain bearings also have changed through the new iglidur® materials.

Beyond the general properties, every iglidur® bearing material possesses a series of special features, which accounts for its special suitability for certain applications and requirements. More information on the structure

With a few application data, a pre-selection and a service life calculation are already possible via the iglidur® product finder and the iglidur® service life predictor respectively. Thereby the great diversity of materials is quickly filtered and the appropriate materials remain.

Which should I choose?

Both iglidur® J and iglidur® W300 belong to the most wear-resistant all-round bearings in the iglidur® range. If the service life is comparable and sufficient in both cases, the boundary parameters should decide the selection of the application: iglidur® J is ideal for wet areas due to low moisture absorption and good media resistance, and iglidur® W300 offers more temperature reserves.

Due to the special structure of the iglidur® materials, which are usually composed of a thermoplastic matrix, fiber reinforcements and the so-called solid lubricants ... The already good wear and friction properties of the matrix or base material are once again optimized by the solid lubricants. During the operation, solid lubricant particles are always sufficiently available on the bearing surface. An additional external lubrication with grease or oil is usually neither necessary nor practical. Video on the question

Why is that?

iglidur® bearings are press-fit bearings for housings with an H7 standard bore. On the one hand, this press-fitting fastens the bearings to the housing and on the other, the inner diameter of the bearings is only formed by that.

The testing of the bearings is done in installed condition in a bore with the smallest dimension. If the bearings are measured in the non-pressed state, they are larger than in installed condition in both outer and inner diameters by the press-in excess.

Despite careful manufacturing and installation of the bearing, variations and troubles connected with installation dimensions and tolerances can arise. Possible reasons for this are:

The position of measurement planes

Bore is not properly chamfered - the bearing scrapes off on the outside.

A centering pin is used to enlarge the bearings' inside when it is pressed in.

The bore does not correspond to the H7 tolerance.

The housing is made of a soft material that gets enlarged by the bearing when pressed in.

The shaft is not H-tolerant.

The measuring doesn't take place within the measuring lines.

Pin gage measurement of iglidur® plain bearings

Which iglidur® bearing is the best?

Unfortunately, there is in general no "best iglidur® plain bearing". Even the most expensive bearing is not the longest-lived in any application. But there is the best iglidur® plain bearing for your application.

It is important always to make the bearing selection according to the application. The more you know about the application, the more accurately we can choose the bearing that suits best technically and economically.

For this purpose, you can use our online iglidur® product finder and iglidur® service life predictor. If you personally don't have the time or opportunity to deal with these tools, just give us information on your application and we do the rest.

Unfortunately no, the color usually results from the respective material composition and often there are only individual dyes that are suitable for a material and also do not influence the tribological properties negatively. Above all, the wear characteristics are dependent on the material composition (which also includes the dye) and a new color additive increases the wear often many times over. Thus each iglidur® material has a certain color, but some materials look almost identical.

iglidur® plain bearings are press-fit bushings. Its inner diameter adjusts with the corresponding tolerance only after the bearing is pressed into the H7 housing bore. The press-in excess can be up to 2% of the inner diameter. The secure seating of the press-fit bearing is ensured with it. Axial or radial displacements in the housing are thus assuredly avoided.

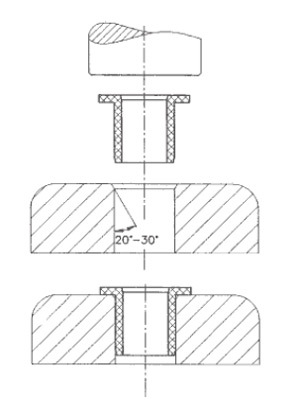

The bore in the housing should be made in the tolerance H7 for all bearings and be smooth, even and chamfered as far as possible. The mounting is done with a level force. The use of centering or calibration pins can lead to bearing damage and a larger clearance.

Force-fitting of an iglidur® plain bearing

In standard cases we have very good experiences with superglues (e.g. Loctite 401). For materials like iglidur® J that are difficult to bond, significantly better results are achieved with 2-component systems (e.g. Loctite 406 + Primer 770). For applications with higher temperatures, we have good experiences with epoxy resin systems (e.g. Hysol).

Moreover, for every bonding connection it is essential that the workpieces are cleaned thoroughly and are free of grease. This can be done with professional detergents, but also with simple fast-acting degreasers. Roughening the contact surfaces also enhances the adhesive effect.

Bonding can generally only be a supporting measure and doesn't fully substitute the press-fit.

1.1 igus®' iglidur® N54 plastic bushings are made out of 54 percent raw, renewable materials.

In the words of Kermit the Frog, “It a’int easy being green." And while he might be just a Muppet, Kermit has a point – these days, many companies are working hard to reduce their carbon footprint on the environment. However, becoming a more environmentally friendly operation does not happen overnight. It is usually a culmination of changes that take place over time, in a number of different areas. So, as a design engineer, what small change can you make to help this cause? While it might sound insignificant, using dry-running plastic bushings can significantly decrease any negative effects on the environment.

Here are four reasons to use environmentally friendly plastic bushings:

1. Plastic bushings do not require lubrication, which keeps the environment cleaner.It is estimated that one billion gallons of industrial lubricants are consumed annually in the United States and about 40 percent of that is released into the environment. Due to continual advances in tribologically-optimized plastic bushing technology, igus® is able to supply metal bushing alternatives more in line with environmental considerations for an increasing number of applications. Unlike metal or bronze bearings that require messy lubrication, every igidur® plastic bushing uses solid lubricants embedded inside millions of tiny chambers that cannot be pressed out. This means the bushings do not require any oil or grease and so no contaminants are released into the environment.

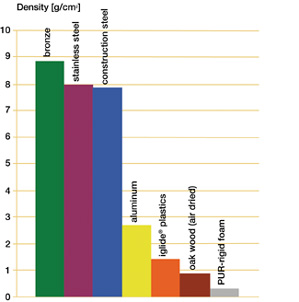

2. Plastic bushings are extremely lightweight, which helps reduce fuel consumption and carbon dioxide output. The reduced weight leads to lower masses and subsequently lower energy consumption.

3. The high chemical resistance of plastic bushings is another positive ecological aspect. Metals often have to be coated using an environmentally unfriendly, high-energy zinc galvanizing bath to achieve this effect.

4. Less energy is required to produce a plastic bushing compared to a metal bearing. For example, the energy from 15 litres of crude oil is necessary to produce 1 litre aluminium and the energy from 11 litre crude oil is necessary to produce 1 litre of steel. In comparison, it only takes 1 litre crude oil to create 1 litre of plastic and we expect this value to fall even further based on continuing breakthroughs in the field of vegetable-oil based plastics.

The heavier a material is, the more energy it needs to stay in motion.

1. Cost factors

Range of iglidur® plastic bearings

Reducing costs is an important factor for most companies. 'The ability to use low-cost shaft materials depends on the bearings chose.

For example, ball bearings require very hard (60HRC or above) and smooth shafting. Bronze bearings are similar: the shafting must be harder than the bronze material being used. Because of these requirements, shafting choices are limited. A less expensive shafting material may not be suitable for the application.

Plastic bushings offer a few more options because they can run on many different shafts. The igus® iglidur® plain bearings are available in a wide range of materials:

Thus you can combine the lowest-priced shaft with the iglidur® bearing material which is most suitable for the application and/or the required service life. Bearing and shaft need to last only so long as the service life of the entire machine/device. - Why select an expensive shaft and/or an expensive bearing that outlast the machine?

2. Aspects of wear

Erosion damage due to a shaft being too smooth.

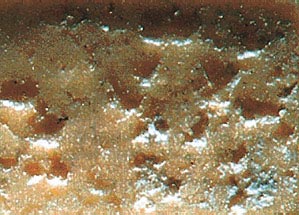

Aside from the cost factors, there are a number of other things to consider when designing shafting into a bearing system. Many things can affect the performance of the bearings used if they are not taken into consideration. If the shaft is too rough, wear can become a problem. Extremely rough shafting can act like a file and separate small particles of the bearing's surface during movement. If the surfaces of shaft and bearing sticking together an increase of the friction can occure when the shaft is too smooth. When there is a large difference between static and dynamic friction, alongside adhesion between mating surfaces, stick-slip— characterized by a loud squeaking noise—can become a problem.

Another important consideration is how hard and soft particles can damage bearings and shafts. If particles get in between a bearing and its mating surface, both can suffer from increased wear. Dirt, dust and paper fibers are just some elements that can cause problems. Bearings with self-lubrication through embedded solid lubricants are more long-lasting in dirt, because there is neither fat nor oil at the bearing position. This means that dirt particles are neither drawn in nor stick to the shaft and the bearing (as can be observed for instance in a well-greased bicycle chain). - This also enables the use of less expensive shafts, even in dirty applications. There are numerous shaft materials on the market, and each of them reacts differently to the wear of a bearing. This includes among others aluminum, case hardening steel, stainless steel and chrome-plated steel. In the end the application conditions and the requirements of service life decide on the shaft to be used. When selecting a suitable iglidur® plain bearing, any standard shaft type can be basically used.

Wear tests with aluminum shafts

Hard chromed shafts, for example, are very hard, but also smooth. The wear of iglidur® plastic plain bearings is on average less in this type of shaft than in other shaft types. A stick-slip effect can occur in individual cases due to the low surface roughness. Various stainless steels are preferred for use in wet areas and in food processing, while hard-coated aluminum is suitable for applications with rather less load and a necessity for low weight. The best coefficients of friction are achieved here in connection with iglidur® J.

1.1 Among other things, igus® ensures through a gage inspection, also called "go/no go test", that our bearings comply with the specifications and work properly after installation.

First, the bearings are pressed into a test housing. Here, take care that the bearings are mounted without damage. For that we recommend a chamfer at the insert – ideally 25-30 degrees. Moreover a press with a level punch is recommended for pressing in the bearings. This is the most efficient installation method. It is extremely important for preserving the integrity of the bearing. For example, if you use a hammer, the installation of the bearing might be uneven.

1.2 igus® recommends using an press to press-fit a plain bearing during installation.

The installation of the bearing is followed by the actual gage inspection. Specifically, a "go" signifies the pin falling through the bearing under its own weight, while a "no-go" occurs when the pin does not fall through the bearing, or "sticks". Usually the gages are graded in 0.01 mm steps, so it can be determined very accurately from which size each gage hangs.

A gage test is the quality check with the highest possible accuracy, because the pin acts like a shaft in a real application and reproduces the narrowest diameter of the bearing. It is usually this aspect that is decisive for the application. Gage inspections are particularly suitable for plastic bearings, as the irrelevant "unevenness" of the bearing due to injection molding is not taken into account. An ideal gliding surface develops later in operation, during the run-in period, when the unevenness of the bearing and the shaft smoothen.

While there are other tests that can be used to quality-check a bearing, inaccuracies can arise when applying these methods to plastic bearings. In particular, the use of a caliper should be avoided. Calipers, depending on the level of accuracy, are generally acceptable for only hurried quality checks. The measurement can become faulty depending on the pressure applied by the gage on the measuring point. For this reason, a gage test is much more reliable.

Depending on accessibility, the described test can also be directly carried out on the serial component (and not in a specifically made test housing).

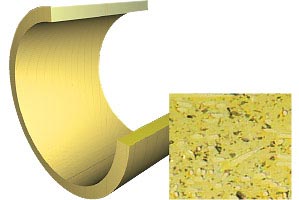

A homogenously structured plain bearing with predictable properties made of a high-performance plastic.

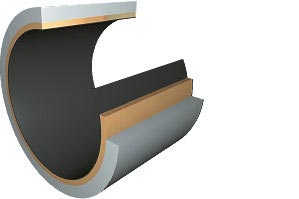

Some engineers hesitate to use plastic bearings in their designs. Maybe they have trusted metal and bronze bearings for years or they simply don't think plastics can handle the tough applications or environments. Plastic bearings, however, can endure extreme temperatures, heavy loads and high speeds. However, it's important to understand both the advantages and disadvantages of the options available. Self-lubricating polymer bearings contain solid lubricants which are embedded in minute particles in the homogenous material. In operation these solid lubricants reduce the coefficient of friction. They cannot be washed off like fat or oil and due to the homogenous structure they are distributed over the entire wall thickness of the bearing. Unlike in a layered structure the entire wall thickness of the bearing is available as a wear zone with almost identical glide properties.

Most iglidur® materials moreover contain strengthening materials which increase compressive strengths. This helps to withstand high forces and edge loads.

Due to this structure iglidur® plain bearings can be used in a wide range of shaft types - depending on the load even on the so-called soft shafts. A cost-optimized combination can thus always be found.

iglidur® bearings made of high-performance plastics should not be compared to bearings made of any standard plastic. You can precisely calculate the service life of iglidur® plastic bearings based on the specific application parameters. igus® offers you an expert system – a special database into which loads, rotary speeds, temperatures as well as further application parameters are entered. Based on the test data, the system then determines a suitable plastic bearing and its estimated service life.

Composite bearings consist of different layers. The soft gliding layer can be easily damaged by foreign particles or improper handling.

iglidur® plastic bushings constitute the step from a simple plastic bushing to a tested, compared and available machine component. The essential advantages combined:

1. No inconvenient lubricants: self-lubricating bearings contain solid lubricants. They lower the coefficients of friction and are insensitive to dirt, dust and other pollutants.

2. Freedom from maintenance: Plastic bearings can replace bronze, metal coated and injection molded bearings in almost any application area. Their resistance to dirt, dust and chemicals make plastic bearings a 'fit-and-forget' solution.

3. Cost savings: Plastic bushings can reduce costs up to 25%. They feature high wear resistance, a low coefficient of friction and can replace more costly alternatives in a variety of applications.

4. Consistently low coefficient of friction and wear: Due to their structure, plastic bearings guarantee a consistently low coefficient of friction and wear throughout their lifetime. Compared to metallic composite bearings, whose gliding layer can be damaged for instance by dirt, plastic bearings often last longer.

5. Absolute corrosion resistance and high chemical resistance: Plastic bearings cannot rust and are resistant to many ambient media.

Every year the igus® engineers develop more than 100 new material compounds

In the course of years the igus® material developers have developed hundreds of material compounds, out of which almost 40 have been entered in the polymer plain bearing catalog. In principle, the setup is mostly the same:

1. Basic polymers which predetermine the basic tribological, mechanical, thermic and chemical properties of the bearing

2. Fibers and filling materials which provide the bearings with a high mechanical load capacity

3. Solid lubricants that significantly optimize wear and friction

igus® is continually developing new polymer blends for every application scenario and conducts more than 10,000 tests in its laboratory every year. Unlike most other bearings manufacturers, igus® focuses exclusively on high-performance plastics and therefore is able to economically process them into plain bearings through injection molding. These polymer plain bearings are used in a wide range of industries, among others: Agriculture, medicine, automotive industry, packaging, aviation, sports equipment, mechanical engineering, etc. In addition, igus® compiles its test results into a comprehensive database. After each polymer blend is tested, the results are added into the data pool for a unique lifetime calculation program: The Expert System, which allows you to enter your application’s maximum loads, speeds, temperatures, and shaft and housing materials in order to calculate the best plastic bearing and its expected lifetime.

1: Wear inspection of an iglidur® polymer plain bearing by igus® in oscillating motion.

Influencing factors:

Shaft selection: Different shafting materials are recommended for different types of plain bearings. Each shaft-bearing combination will have different wear results.

Load: With increasing radial loads and/or surface pressures, the wear of the plain bearings also rises. Some plain bearings are designed for low loads, some for high loads.

Speed and type of movement: With increasing speed the wear also increases. The type of movement (oscillating, rotating or linear) has considerable influence on the rate of wear.

Temperature: Within certain limits, the temperature barely affects the wear of a bearing, but it can also exponentially accelerate the wear. Depending on the material selection, plastic bearings are indeed suited for a wide temperature range. However, when the maximum application temperature is exceeded, the wear can increase significantly. In most iglidur® materials the rate of wear increases with rising temperatures. There are also exceptions, which only reach their minimum wear at higher temperatures.

Dirty surroundings: Dirt and dust can accumulate between shaft and bearing. That causes wear. Self-lubricating plastic bushings offer an advantage in this situation: they operate oil-free so dirt and dust will not score the shaft or damage the bearing.

Contact with chemicals: Polymer plain bearings are absolutely corrosion-free and resistant against a wide range of chemicals, but certain chemicals can even change the structural properties of a plain bearing, which decreases the bearing's hardness and increases the wear.

2: Wear tests using different types of shafting.

Applicable to all these points is: the better I know my application and the mentioned parameters, the more specific the iglidur® material selection and service life prediction can be. The selection of the right material is decisive for the service life.

Bearing wear means removal of material on the gliding surface, which usually means at the inner diameter of bearing.

The clearance between bearing and shaft can be calculated from the tolerances of bearing and shaft.

The real start clearance at the commissioning is the difference between the measured actual inner diameter of the bearing and the measured actual outer diameter of the shaft. Wear at the inner diameter of bearing results in an increased diameter and thereby in an increase in play.

As iglidur® plain bearings have no layered structure and thereby the entire wall thickness is available as a wear zone, the bearing has no specified wear limit. Instead the wear limit is determined by the permitted maximum clearance in an application. It can differ widely depending on application and user requirement. Precision control valves only allow for a few hundredths of wear (and thus increase in clearance). In agrarian applications with shaft diameters larger than 50 mm, a clearance of significantly more than a millimeter is not crucial.

As a general rule, xiros® polymer ball bearings are preferred over iglidur® plain bearings in all situations where rotating motions can continuously occur at speeds of 1.5 metres/second at low loads. In comparison to plain bearings, polymer plain bearings have a significantly lower friction value, which generates less heat and exhibits lower wear.

The inner diameter of the ball bearing is a key parameter. As the inner diameter becomes smaller, the bearing performs fewer rotations per minute, which in turn has a positive impact on the generated heat and thermal transfer. As the diameter of the ball bearing increases, the maximum load-bearing capacity increases, whereas the maximum rotational speed decreases.

Our dual row polymer ball bearings are suited for applications with higher bearings loads. We supply sealed xiros® ball bearings for applications with dirt and abrasive material exposure."

The stick-slip effect refers to the intermittent gliding characteristics when two solid bodies slide against each other. The phenomenon occurs when one body is moved whose static friction is significantly greater than the dynamic friction.

Imagine pushing a heavy cardboard box across a smooth floor. The cardboard box is heavy, which is why we need to apply great force to overcome the static friction - that is to say the resistance of the cardboard box against being moved. The cardboard box glides. Due to the smooth surface and the resulting low dynamic friction, the carton quickly accelerates. Because of the rapid gliding motion of the cardboard box, we are only able to transfer a small force to the cardboard box. Ultimately, the force applied on the carton is insufficient to overcome its static friction. The cardboard box comes to rest, which is why we need to again apply great force to overcome the static friction, and the process repeats. Rest – break away – glide – decelerate – rest – break away… in reality, this effect is executed at much greater speed and is manifested in chatter. .

This phenomenon occurs in a wide range of applications. Windshield wipers chatter across the windshield on a car. When held at an incorrect angle, chalk squeaks across a blackboard when writing. Door hinges squeak. And string instruments such as violins or cellos would not work, for their notes are created by oscillations and vibrations created by stick-slip effects between the strings and the hair on the bows. .

However, this effect is undesirable on tribologically optimised materials. The resulting vibrations are transferred to the overall structure and cause noise that is frequently perceived as squeaking or chatter. The desired gliding motion is transformed into irregular chatter and increases bearing wear. These effects can be counteracted by minimising the difference between the static and dynamic friction, by employing vibration-damping materials, and by improving the stiffness of the overall structure (see pre-tensioned bearings), or by separating the involved friction partners (e.g. with lubricant)

1. Force > static friction

The force (vector 1) overcomes the static friction (vector 2). The cardboard box starts to move.

2. Force = static friction

Static friction is transformed into dynamic friction (vector 2) and the cardboard box glides rapidly.

3. Force < dynamic friction

The force (vector 1) is insufficient to overcome the dynamic friction (vector 2).

4. Force < static friction

Dynamic friction is transformed into static friction. The force is insufficient and the cardboard box come to rest.

EC Directive 2002/95/EC ("RoHS 1") was replaced by EC Directive 2011/65/RU ("RoHS 2") on 3 January 2013.

The directive governs the restrictions on undesired ingredients in electrical and electronic equipment sold within the EC. The RoHS abbreviation means "Restriction of (the use of certain) Hazardous Substances" .

Specific threshold values were established since there are technical limitations in many materials and products that do not permit a complete elimination.

The affected substances are frequently used in electronics and include lead, mercury, cadmium, hexavalent chrome, polybromated biphenyles (PBB) and diphenylether (PBDE). Application examples include the use of lead in solder, or as an ingredient in metallic composite bearings, and the use of PBB as a flame retardant. The substances also frequently occur in metallic alloys.

As a look at the substances and these usage examples shows, these substances are irrelevant to thermoplastic polymer compounds such as our iglidur® materials. The substances contained within our iglidur® materials therefore fulfil the requirements of Directive 2011/65/EU (RoHS 2). We will gladly send you explicit confirmations on request.