iglidur® - Features

Beyond the general properties, every iglidur® bearing material has a series of special features, which accounts for its particular suitability for certain applications and requirements. The detailed description of the materials can be found in the respective sections before the tables of the available dimensions.

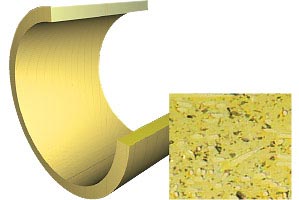

Figure 1.1: iglidur® bearings are homogeneously constructed. Base polymer, composite materials and lubricants complement each other.

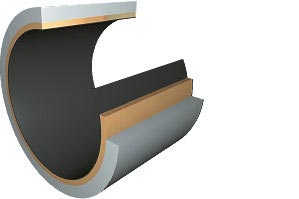

Figure 1.2: The traditional solution, layered bearing shell with lubricant and coating respectively.

Picture 1.4: iglidur® plain bearing: The appropriate bearing for every application: FDA compliant iglidur® A180 plain bearing for the wet area

Picture 1.5: base polymer with fibers and solid lubricants, magnified 200 times, colored

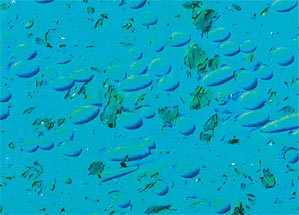

Picture 1.6: Base polymer without reinforcements with solid lubricants, magnified 50 times, colored

X = Time

Y = Wear

Figure 1.3: During the run-in period, the wear rate reduces strongly.

The high-performance polymers of the iglidur® bearings consist of: Base polymer Fibers and filling material Solid lubricants

These components are not laid on in layers, but homogeneously compounded. The advantage of this construction becomes particularly clear if you look for once at the requirements posed on the surface of a bearing:

2. The surface must not be pushed aside under the forces acting on the bearing.

3. As the wear forces especially act on the bearing's surface, the bearing should be particularly resistant there.

There is no universal material available that can fulfill all these tasks equally well.

Hard shell with soft coating. Every lubricated bearing works according to this principle, aside from a series of maintenance-free bearings equipped with special sliding layers. However this soft sliding layer is not strong enough. With high loads, misalignment or vibrations, it is shoved aside.

To fulfill each requirement of the bearing, there is a component of the iglidur® materials: The base polymer is crucial for the wear resistance. Fibers and filling materials reinforce the bearing to take high forces or edge loads. Finally the solid lubricants automatically lubricate the bearings and prevent friction in the system.

Integrated lubrication

The solid lubricants are embedded as microscopic particles in the millions of minute chambers of the solid, mostly fiber-reinforced material. The bearings release minute amounts of lubricants from these chambers. That is adequate to sufficiently lubricate the immediate surrounding.

The radial pressure acting on the bearing is taken by the polymer base material. It rests on the shaft at the contact surface. It takes care that the solid lubricants are not submitted to high bearing pressure. The base material is additionally reinforced by technical fibers or filling materials. These additives stabilize the bearings especially for constant stressing.

In the initial phase the shaft and the iglidur® bearing run in on each other. During this period, the surfaces of both partners ideally adapt to each other. The specific load of the system lowers as the contact surfaces of the shaft and bearing enlarge during the run in. Simultaneously the wear rate lowers and approaches a linear run. In this period, the coefficients of fiction alters itself in order to eventually adopt a largely constant value.

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!