Improve technology and reduce the costs by 25% and more.

Countless design options on the basis of the drylin® W linear guide construction kit

Glides instead of rolling! Lubricant-free through dry-tech® polymers

igus® linear guides are made from maintenance-free, e.g. self-lubricating high-performance plastics. The lubricant is incorporated into the bearing material, rendering the bearing materials suitable for dry-running conditions, e.g. they are maintenance-free for the entire length of their service life. By eliminating lubricants, igus® linear systems are

Modular system

Use the technical product advantages of our maintenance-free drylin® W linear construction kit:

1.1. Resistant against dirt, dust, moisture absorption

Particles are repelled from the contact surface by the movement.Details of working principle

drylin® linear bearing systems are designed for dry-running. All applications are therefore protected against contamination with grease or oil. Even the application under coarse dirt and sand is possible.

igus® tested

Dirtparticles are repelled from the contact surface by the movement itself. Here the front side of the gliders works like a wiper. The contact surface remains clean.

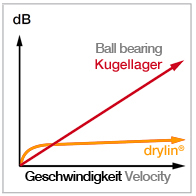

1.2. Low noise

Details of working principle

The operating noise is also greatly reduced by switching the operating principle from rolling to gliding. There is no mechanical rolling up of hard gliding partner and no ball collisions that cause loud noises.

igus® tested

The gliding motion is extremely low noise and only a light friction noise is audible.

1.3. Clean and hygienic

Details of working principle

The dry-running properties of iglidur® plain bearings are not only advantageous in contaminated environments. The absence of lubrication is also an important criterion in applications with elevated requirements for hygiene and purity.

Tested

The tested drylin® guides reveal a distinct applicability for cleanrooms. The following drylin® guides from igus® were tested: N40, W10, T25 and T30.

1.4. Resistant to corrosion

Details of working principle

All iglidur® plastic plain bearings are by their nature corrosion-free. There are also special purpose materials, which can be used against caustic solutions, acids, cleaning agents, etc., and, due to their media resistance, can be used even under the most adverse conditions. - The product range also has special purpose materials for permanent use in submerged conditions.

Application example

In the development of the machine, the responsible engineering firm Dr. Dorstewitz decided on the comprehensive use of polymer plain bearings, which reliably operate under these rough environmental conditions. In total, 239 igus® plain bearings are installed in the new machine.

2. bearing materials

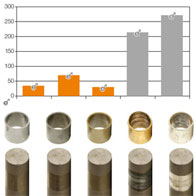

Materials for any shaft material, superior specific wearDetails of working principle

Depending on their application, linear guides can be adjusted in regard to the plain bearing material. For instance, iglidur® A180 was developed for applications that require an FDA compliant solution.

igus® tested

igus® provides various materials for gliding elements and counter partners for linear systems. Extensive lab tests and years of field experience have shown that iglidur® J, J 200 and X are the ideal materials for most linear applications due to their favorable wear and friction properties.

Application example

By changing over to the drylin® R linear plain bearing, the maintenance rate of this compaction unit could be extended by 2 years, despite high stressing from powder particles and abrasive agents. The previous recirculating ball-bearing solution necessitated a replacement of bearings and shafts every 2 to 3 months due to worn shafts.

3. Selecting the ideal housing bearing material

Zinc die-casting: cost-effective standard bearing

Aluminium: low component weight

Stainless steel: corrosion-resistant and also for high temperatures

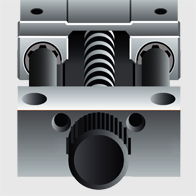

Turn-to-fit mechanism: Manual adjustable clearance by „Turn-to-Fit“ function with allen key

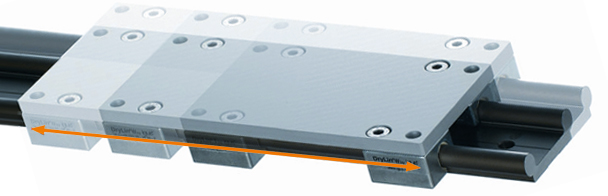

4. Selecting the ideal carriage length

Guide carriages are available from stock in various standard lengths, e.g. 100mm , 150mm und 200mm.

5. Various rails available, various diametres and versions

Details of working principle

We will cut the guide rails to your desired length. There is no minimum length and also no maximum stroke length.

igus® tested

Guide rails can be connected in series, since the glide element can travel over the rail joints with ease. This facilitates stroke lengths of more than 20 metres. Assembly is simplified by the distinctive joint marking provided at the factory.

6. Large construction kit of guide rails

Rectangular, round, as individual or double rail, Ø 6mm, 10mm, 16mm, 20mm, also with manual clearance adjustment.Single Rail

Installation size (square): 6 - 20 mm

Installation size (round): 10 - 25 mm

Double rail

Installation size (square): 6 - 20 mm

Installation size (round): 10 - 25 mm

Rail widths

Wdths: 30 - 120 mm

7. Highly flexible - you determine length and width

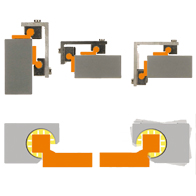

Variable width, length, installation type. As fixed and floating bearing systemsDetails of working principle

drylin® W linear guides support highly flexible uses. Alignment and parallelism errors can be compensated by using floating bearings.

igus® tested

There is a suitable fixed-/floating-bearing solution for every installation location, whether it be horizontal, vertical or lateral. This installation method prevents a sluggishness and/or a jamming of the guide with parallelism deviations between the guides.

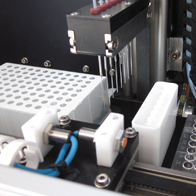

Application example

Fit-Equip sought for cost-efficient solutions to replace the previously employed guide systems. Besides an appealing design, the linear guide should be additionally quiet and absolutely lubricant-free. Guide systems from the drylin® W modular kit system were selected.

8. Surface contact

No point loads, as is for instance the case with recirculating ball bearing systems.The application of non-hardened shafts is possible.

Even non-metallic counter-partners are usable

A galling is completely excluded.

Details of working principle

The use of liners made from high-performance plastics allows the plain bearing to be in contact with the shaft across the entire surface. Thus a considerably larger contact surface becomes available resulting in a much lower surface pressure.

igus® tested

Because of the large surface contact in comparison to the point load on a recirculating ball bearing guide, softer, frequently also more cost-effective shaft materials (e.g VA) can be used in addition to hardened shafts.

9. Hard-anodised aluminium rail

Details of working principle

igus® plain bearing materials are matched to their counter partner with respect to friction and wear characteristics. One attains the longest service life in combination with anodised aluminium. The function and service life of your application can be calculated on-line via freely accessible service life calculation programs.

Application example

By changing over to the drylin® R linear plain bearing, the maintenance rate of this compaction unit could be extended by 2 years, despite high stressing from powder particles and abrasive agents. The previous recirculating ball-bearing solution necessitated a replacement of bearings and shafts every 2 to 3 months due to worn shafts.

10. numerous accessories

Details of working principle

In addition to the classic guide, consisting of guide rail and guide carriage, the linear system can also be customised to suite your needs.

igus® tested

drylin® W is available as a measurement system unit, with manual clamp, clearance adjustment, in stainless steel, as a mono slide and with hybrid bearings.

Application example

Individually adjustable bearings, manual clamps, hybrid carriages "Rolling instead of gliding" and more ensure shock-free, lubricant-free gliding in camera systems.

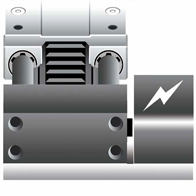

11. drylin® drive technology

Details of working principle

Based on our drylin® W linear construction kit, we can also provide drive units based on a lead screw or timing belt. The systems can be customised to suit your needs.

12. drylin® E

Details of working principle

The "E" stands for "Electric" and completes the igus® product range with hybrid stepper motors, DC motors, proximity switches and the proven chainflex® motor cables.

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!