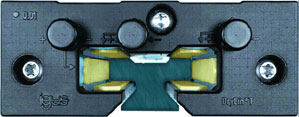

DryLin® is a range of maintenance-free and lubricant-free linear bearings in four different type series. In addition the range is complemented by complete linear units with spindle drive or toothed belt.

Besides the freedom from maintenance and lubricants, the main features include ruggedness and the insensitivity to dirt, water, chemicals, heat or impacts.

DryLin® - Glides instead of rolling!

Linear motion: Lubrication-free plastic glides instead of balls

maintenance-free

lubrication free

Resistant to dirt, dust and humidity

Weight reduction

For short-stroke applications

Self-lubricating

Very quiet run

wear-resistant

Corrossion-resistant

Insensitive to impacts and vibrations

Low coefficients of friction

High static load capacity

High speeds and accelerations possible

Low magnetism

(in german)

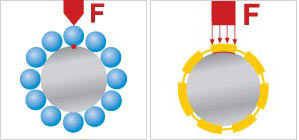

Instead of balls (left): Lubrication-free plastic glides (right)

DryLin® linear bearings operate on gliding elements unlike the familiar recirculating ball bearing systems. Thus an essentially larger contact surface becomes available resulting in essentially lower surface pressure. The resultant advantages are:

The application of non-hardened shafts is possible.

Even non-metallic counter-partners are usable

A galling is completely excluded.

Due to the large surface load distribution of the drylin® linear plain bearings compared to the ball lining, softer shaft materials can also be used. Thus the hard-coated aluminum shafts offer the best friction and wear coefficients, carbon fiber shafts, the lightest weight and stainless steel shafts, the highest chemical resistance. Of course the use of hardened steel and stainless steel as well as hard-chromed shafts is also recommended.

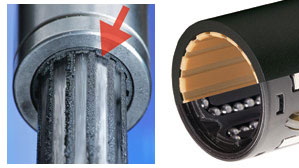

Resistant to dirt, dust and moisture - left DryLin®, right a comparison of DryLin® with ball bearings

DryLin® linear bearing systems are designed for dry-running. Your applications are thereby protected against soiling by grease or oil. Even the application under coarse dirt and sand is possible. Particles are repelled from the contact surface by the movement itself. Here the front side of the gliders works like a wiper. The contact surface remains clean.

The quiet run is also based on the feature of gliding in contrast to rolling. There is no mechanical rolling up of hard gliding partner and no ball collisions that cause loud noises. The gliding motion is extremely low noise and only a light friction noise is audible.

Rail joint

The line up of guide rails (joining) poses no challenge for drylin® linear guides. The guide rails are slightly chamfered, aligned and simply placed behind each other. The groove resulting from the joint can be passed over by the gliding element without problems. With the drylin® linear plain bearings, a ball or roller cannot get stuck. In this way stroke lengths of more than 20 meters can be implemented. The assembly is facilitated by the distinct marking of joints provided at the factory.

DryLin® linear plain bearings do without rolling objects or balls. This makes the bearing independent of the mass inertia of this body and can be used with high speeds up to 10 m/s and accelerations up to 100G. DryLin® linear bearings are thus suitable for applications with light loads, whose cycle rates should be increased. The use of hard-coated aluminum as a friction partner lowers the operating temperature in the bearing due to the high thermal conductivity of aluminum. Thus the operation can be carried out with a high frequency even at very short stroke lengths.

The maximum average surface speed results from the load on the bearings. With decreasing surface load, higher speeds can be achieved. More important than the maximum speed reached is the average speed in a period of time, because it has the most influence on the heating of the bearing system. In cases with breaks between the individual cycles, the maximum average surface speed is decisive, which is achieved during a period of 10 to 30 minutes.

| Heat conductivity | [W/m x K] |

|---|---|

| Aluminium | 235 |

| Unalloyed steel | 48-58 |

| High-alloyed steel | 15 |

Average surface speed = Travel distance per cycle [m] / total cycle time [sec].

Extreme application conditions in the offshore sector

The low humidity absorption of iglidur® J, J200 and X permits even underwater applications. The application of stainless steel or anodized aluminum shafts provide for a corrosion-resistant guide system. Anodized aluminum is resistant to chemically neutral substances in the range pH 2 to 7.

For special cases of application, separate tests are recommended for coated aluminum sample parts for that specific application.

Filling machine, Krones AG, Rosenheim

iglidur® J is resistant to weak acids, diluted alkalis as well as to fuels and all kinds of lubricants. The intensive cleaning of machines with standard commercial cleaning agents, even in the food sector, is thus not a problem for the guides.

For applications in environments with extreme chemical loads, the application of the DryLin® R bearings equipped with iglidur® X liners is recommended.

The resistance of linear bearing systems is equally dependent on the counter partner. As a partner most resistant to chemicals, a high-alloyed stainless steel is offered, for instance X105 CrMo 17 (1.4125), or alternatively the use of soft VA steels (e.g. 1.4571).

The iglidur® X material in heavy-duty use under high temperatures in foundries

Gliding elements made of iglidur® J and J200 can be used in the temperature range between -40 and +90°C. Bearings with higher accuracy classes could have alternative temperature ranges. Please note the hints on the serveral product pages. In applications with aluminum shafts and/or rails, distinctly higher loads and speeds can be attained due to the excellent heat conductivity. Gliding elements made of iglidur® X can be used in the range of -100°C to +250°C.

Lubricant-free and insensitive to dirt

Use in dirt

Even the application under coarse dirt and sand is possible. Particles are repelled from the contact surface by the movement itself. Seals can be deliberately dispensed with due to the dry operation. Dust and dirt cannot stick to grease or oil.

Hard anodized surfaces

Hard anodized surfaces are characterized by good wear properties, high chemical resistance and a high degree of hardness. It is a technical surface, not a decorative one. Color variations and slight cracks therefore cannot be prevented due to production reasons, but have no effect on the resistance, the corrosion behavior or glide properties. Cut surfaces and reworked surfaces are uncoated.

Lubricant-free and clean

Use in wood chips

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!