DryLin® N miniature gliding systems - basics

DryLin® N low profile guide systems

DryLin® N low profile guide systems offer you low profiles in various widths. Like in all drylin® products, the carriage runs without lubrication in anodized aluminum profiles. The material used and the unique design make DryLin® N a cost-efficient and flexible guide system.

Technical data

| Gliding elements: | Maintenance-free |

| Material: | iglidur® J * |

| Max. surface speed: | 15 m/s |

| Operating temperature: | -40°C to +90°C |

| *Other materials on request |

Rail made of anodized aluminum

2Gliding elements made of iglidur® J or J200

3Carriage made of chromated zinc or plastic

4Carriage with threaded hole or through hole

Small installation height between 6 and 12 mm

Lightweight

Numerous carriage options – also with pretension

Maintenance-free, self lubricating

Corrossion-resistant

Low wear with low coefficient of friction

Rails in silver or black anodized

DryLin® N - Installation video of the gliding elements

NW 17 = 17 mm rail width

NW 17 = 17 mm rail width

The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications.

Variants: Standard, Preload (P), floating bearing (LL)

extrem low weight

Quiet running

Installation height 6 mm

up to 50 N load

NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series.

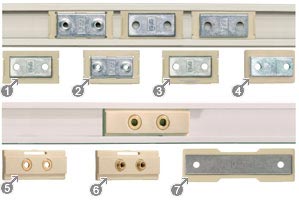

1. NW-01-27 standard 01 with through hole g

2. NW-02-27 standard 02 with threaded hole

3. Preload with through-hole or threaded hole

4. uinjection-molded with through-hole or threaded hole

5. NW-21-27-60P Vollkunststoffschlitten mit Durchgangsbohrung

6. NW-22-27-60P solid polymer carriage with through hole

7. NW-11-27-80 double carriage with through hole

NW 27 = 27 mm rail width

NW 27 = 27 mm rail width

The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation.

NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged.

Over 20 carriage options

9.5 mm installation height

100% lubricant-free

iglidur® J plain bearing material

up to 500 N Last

Best selling linear guide

1. Standard 02 with threaded hole

2. Injection-molded with threaded hole

3. Standard 01 with through hole

NW 40 = 40 mm rail width

NW 40 = 40 mm rail width

The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded.

Lightweight

Installation height 9,5 mm

high speeds are possible (up to 5 m/s)

iglidur® J plain bearing material

up to 700 N Last

NW 80 = 80 mm rail width

NW 80 = 80 mm rail width

The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation.

Installation height 12 mm

100% lubricant-free

Wide torque support

up to 1000 N Last

Gliding elements made of iglidur® J or J200

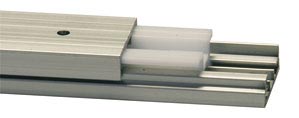

Telescope system

Telescope system

Mounting rails: Anodized aluminum

Intermediate rail: Plastic

Options: Full extension, over extension (+ 20 mm), partial extension

Continuous lengths up to 1200 mm extended total length

Lubricant-free

Low noise

Corrosion resistant

From stock

End caps.

The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way.

Easy installation

Low-priced

Dismantling possible

High retention force

Low profile linear axis - SLN-27-01

SLN-27-01: Linear axis for manual operation with hand wheel

(SHT-HR-05-22-15-OG)

SLN-BB-27-01: Ball bearing linear axis for

manual adjustments with hand wheel 100 /

150 / 200 / 250 mm strokes

Small (installation height from 22 mm), light and flat

Plastic plain bearings in the bearing points

Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm

Manual and motorized operation

Low profile linear axis - SLN-27-02

SLN-27-02: Linear axis with NEMA11 stepper motor,

ball bearing spindle over motor bearing

SLN-BB-27-02: Ball bearing linear axis with

NEMA11 stepper motor

Small (installation height from 22 mm), light and flat

Plastic plain bearings in the bearing points

M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7

Manual and motorized operation

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!