The Optisort machines, which he subsequently developed, use camera technology in connection with automated feeding and very fast computing systems.

If you see such a system in action, the speed is impressive: Going

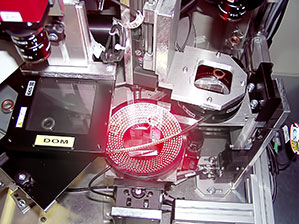

out from a bunker system via a vibrating conveyor, the specimens are isolated, correctly positioned if necessary, fed and guided past the camera either on a glass plate, a special metal plate for screws, or a conveyor belt. Even 360° inspections with four cameras are possible. Good parts are regularly discharged, defective parts separated.

All this happens at a speed with which the human eye can barely keep up. "The systems check several hundred parts per minute, sometimes more than 50,000 pieces per hour," says Thomas Rothweiler. They are very flexible, because they inspect different components: "Each machine typically checks 200 to 300 products. " Each product has its own test programme installed.

Test specimens in the right light

drylin® linear axes in high-speed test equipment

Visual inspection of small components in very large quantities: The Gefra GmbH in Friedewald/Westerwaldhas made the automation of this task its business - thereby making it successful worldwide. For the electrical adjustment

of lighting units, Gefra uses complete linear drive units

from the drylin® product range.

How to check for damage 900 screws or 700 injection moulded parts per minute?

Those who ask this question will find the correct answer at the Gefra GmbH.

Because the company, founded in 1995, specialises in developing automated

equipment for the fast and accurate visual inspection and measurement of

components.

Reason for founding the company was the knowledge that this need exists. Dipl.- Thomas Rothweiler, founder and managing partner of the company, advises production companies in streamlining and automation. At the same time, he notes that at the end of highly automated processes it is often necessary to examine by the human eye and sort manually.

The modularly constructed Optisort systems inspect small parts such as screws, gaskets and moulded components.

With the continuous advancement of equipment, the mechanical system, i.e., the feeding at such a fast pace, encountered its limits in the past. In some cases, the computing speed of the available controls also reached its limit, as is evident when you consider that sometimes eight or ten cameras inspect the test item and the control must decide within milliseconds whether it is "good" or "bad".

Even when each machine is individually adapted to the wishes of the customer, Thomas Rothweiler emphasises that it is not about special mechanical engineering: "Our machines are based on a modular principle and we use very many identical parts. “

A recent advancement concerns the lighting by which the test specimens

get the right light for the cameras. The spacing of the lights to the test object varies depending on the product, and the user adjusts the lights manually using an adjusting wheel with scale. The aim of Thomas Rothweiler was to integrate this process in the controller and thus make it reproducible. In this way, not only manual process steps are saved, but possible incorrect settings are also excluded. Even more important was the ability to integrate the position of the lights in the documentation.

In search of suitable linear drives, the Gefra engineers made their find in the drylin® product range of igus®. igus® has developed the drylin® E range based on the drylin® linear axes, in which a carriage made of the iglidur® high-performance polymer travels with the aid of a drive screw. (E as in electric). These are complete linear drive units, in which a stepper motor drives the axis via an optional flange and an optional dog clutch.

With this axis Gefra creates the prerequisite for the lighting adjustment in the PC controller and thus be integrated in the respective test protocol and to advance the automation of another step. Here an axis with 60 mm stroke is used, which is driven by a NEMA 17 stepper motor and moves loads up to 1000 g with an accuracy of +/- 0.5 mm.

Everything from a single source: In the drylin® E units, carriage and stepping motor are combined into a ready-to-connect unit.

A very important criterion for the selection was the lubricant-free operation of lead screw and carriage: Since the lighting units are directly above, adjacent and below the test specimens, the drives must not release any foreign substances that could affect the inspection process.

Equally important was the compact design of the drive units. Thomas Rothweiler:

"As we offer the electrical adjustment as an option for the future, they must allow the integration in the existing structure. Important to us is also the fact that we procure the entire unit with motor, carriage and mounting, ready for installation from

a single source. “

The new concept has already been tested in a system that checks gaskets. Four lead screw linear tables of the type drylin® SAW-0630 with electric drive, motor flange and integrated dog clutch are connected via the controller to the PC of the system.

The drives perfectly fit in with the surroundings.

By the way, one greatly appreciates the benefits of Optisort systems at igus®.

Because, in the Cologne production centre, altogether four Gefra systems are involved in the testing of plain bearings. Mostly, these are safety-related components that igus® produces for the automotive industry and which need to be tested

100 percent. igus® now plans to acquire a fifth Optisort system.

If the people in charge choose the option of an electric lighting adjustment, some of the drylin® E units delivered to Friedewald are coming back to their place of origin.

The drylin® linear unit when installed

View of the process: Checks are done here, and at extremely high speed.

Group picture with linear drive. From left to right: Dipl.-Thomas Rothweiler, managing partner of the Gefra GmbH, Dipl.-Ing. (FH) René Erdmann, igus® product manager drylin® E drive systems and Markus Schwarz, technical sales consultant at igus®.

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!