Intelligent conveyor chain with integrated power & data supply

Give each conveyor link a separate function.

Equip it with grippers, suction cups, tools, sensors, cameras, and, and, and…

Reduce pick & place times drastically. Up to 30% faster.

Intelligent conveyor chain with integrated power & data supply

Give each conveyor link a separate function.

Equip it with grippers, suction cups, tools, sensors, cameras, and, and, and…

Reduce pick & place times drastically. Up to 30% faster.

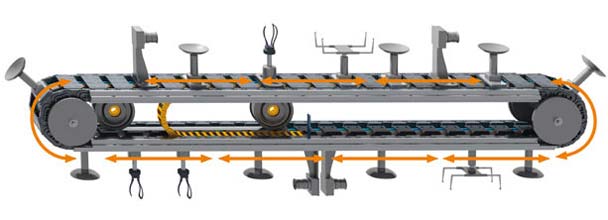

Function and installation types for the pikchain® conveyor chain

Interview with Andreas Hermey, Development and Design Manager regarding the special operating principle and potential uses of the pikchain®. Interview (German)

Potential uses of the pikchain® conveyor chain in the wood industry.

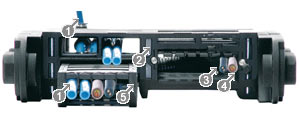

C-Chain

2Gliding elements made of iglidur® J

3Air duct, transition from the c-chain to the pikchain®

4Pneumatic hoses

pikchain® as a vertical conveyor for cardboard boxes (ASA in Mainhausen)

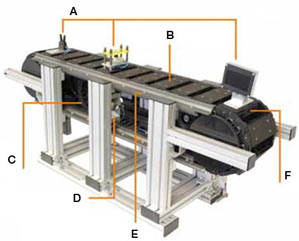

Study: three pikchains® as interacting components for an analysis and sorting machine for technical components

A = machining units / tools

B = planar assembly surface

C = c-kette

D = = Main feed

E = Maintenance-free linear units

F = Circlet cable

The pikchain components offered by igus® give you the ability to design your customized "pick and place" robots.

The pikchain® side plates with tribological plastic gliding elements. The gliding elements glide in the guide trough. The abrasion and service life depend on three parameters: Speed, weight or surface pressure, and the gliding partner material (hard-anodized aluminum rail and plain bearing plastic).

Based on 40 years of experience and thousands of tests, igus® can always determine the ideal materials pairing for your application. The gliding elements can be purchased later as a replacement part, and are assembled with ease.

C-Chain

pikchain® links

Guide troughs

Rotary union (slip ring)

Chainflex® cables

Chainflex® CF Air hoses

Frame

Motor

Gears

Guide rollers

Tools, such as suction cups, grippers, etc.

Programming/control system

The pikchain® can be mounted horizontally, vertically, or lying on its side.

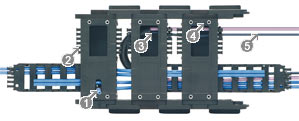

Pneumatic hose

2Conveyor chain link

3Energy

4Bus cable

5C-Chain

Pneumatic hose

2Integrated strain relief

3Media supply system

4Tool holder

5Chainflex® cables

Example: Pick and place of a work piece with pickchain®

The igus® pikchain® could conceivably use a variety of grippers, suction cups, sensors, cameras, etc.

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!