1. Bottom web feeder

2. Forming station / deep-drawing process

3. Infeed section

4. Top web infeed / labeling

5. Sealing unit

6. Cutting station (crosswise / lengthwise)

Form- Fill- and Closing Machines

Typical materials and products

To find in applications like:Tool guide system

Filling process

Film welding unit

Guides for the deep drawing process

Overview

Advantages:

No lubricants at the products

Maintenance-free

Wear-resistant solution in spite of cleaning process

Dirt accumulation

Advantages:

Fastest demounting of bearing

Cost advantage

Cleaning with hydrogen peroxide possible

Dirt accumulation possible

Advantages:

Cleaning with hydrogen peroxide

Recirculating ball bearing is no alternative (cleaning)

Cost saving

Combination with soft

stainless steels possible

maintenance-free

Wear-resistant solution in spite of cleaning process

Advantages:

No washing-out of the lubrication

No corrosion of the ball (soft stainless steel ball instead of hardened ball)

Lower adhesion factor, than bush bearing

Resistant against chemicals

Advantages:

Cost advantage

Easy to install through split bearing housing

No rinsing of the recirculating ball bearings

Good corrosion-resistance

Advantages:

Vibrations during punching have no influence on the shaft

For this reason: No shake down of the shaft

Cost saving

Combination with soft stainless steel shafts

Maintenance-free

No impact from dirt accumulation through punching waste

Application example

Linear stroke of the surplus-film winder with the combination of drylin® hard anodized aluminum precision shaft AWMP and iglidur ® J bearings.

Height adjustment of the discharge conveyor implemented with iglidur® J bearings.

Main mounting of the bottom web dancer plate via igubal® flange bearings EFOM-30.

Standardized toggle lever stroke system in the sealing unit. Vertical guidance upper-stroke (J bushings), toggle lever mounting iglidur® Z, main guide columns (JUM-02-45).

Standardized linear stroke system - Forming station Toggle lever with iglidur® Z, main guide columns with drylin® linear liners JUM-02-45.

Mounting of the film guide rollers on the Tiro-Lable NT (labeler) using xiros® ball bearings.

Mounting of standard safety door with maintenance-free iglidur® A180 bearings (FDA approved).

Mounting of the preheating stroke (sealing unit)

Mounting of the disc brake of the bottom web mandrel via iglidur® A180 maintenance-free bearings (FDA approved).

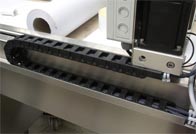

Energy supply system of the XY travel unit of the inkjet printer for printing the packing date on the label with igus® e-chain® easychain.

More application examples

Packaging machines

The iglidur® G plain bearings distinguish themselves by their wear resistance and the suitability for real dry operation in this packaging machine for polishing cloth.

Filling and sealing machine

Besides the high chemical resistance, the iglidur® J plain bearings offer a maintenance-free dry operation in this application.

Forming, filling and sealing machine

DryLin® high temperature bearings are used in the tool guide system of this forming, filling and sealing machine.

Automatic cup supply system for cup filling line

No lubricants in food sector

Horizontal forming, filling and sealing machines

On these horizontal forming, filling and sealing machines, the total freedom from maintenance over the machines' entire life cycle was particularly important for the customer.

Product choice

Your contact

Lars Braun +49 2203 9649 218 Your requirements?

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!