Quiet, fast and efficient

Roller energy chains®® for a highly dynamic linear gantryTo process its work pieces, the end customer from the automobile industry needs loading gantries with very high holding times. These must operate quietly and simplify processes. This works at notably higher dynamics. The OEM supplier supplies low-wear roller energy chains® for this complex new development. These can have a smaller configuration, but can also operate very quietly and will stand up to the high accelerations and speeds over the long-term.

"We have redesigned our gantry system from the ground up", explains Grad.-Eng. Peter Vogl, Director Design & Development at GROB-Werke GmbH & Co. KG in Mindelheim. "We based our efforts on the market developments, the needs of our customers in the automobile industry, and the respective machining processes of their work pieces. "This relates to all manufacturing steps that can occur on castings or forgings.

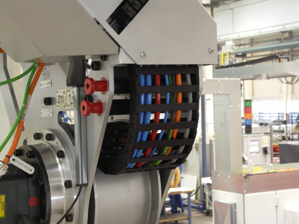

A linear gantry is being assembled in the production area. The roller energy supply stands up to high acceleration and speed over the long-term. Machine availability is not compromised.

The underlying focus is always the issue of how the various work pieces can be machined in the fastest, most cost effective, and therefore most productive manner possible, without compromising work piece quality or machine holding times.

The company has developed a new linear gantry, also called transfer machine, which was presented very successfully at EMO. Its key features are that it is notably smaller and more compact than previous solutions. "Our objective was to create uniform, simplified loading processes", Peter Vogl elaborates. "This can only be achieved with dynamics." This then quickly leads to the issue of a matching energy supply. We tested a host of solutions and ultimately decided in favor of our long-standing supplier of energy supply systems. “

The linear gantry employs roller energy supply systems. The advance tests compared the performance of magnetic chains and plastic energy chains®. The decision left no doubts: internal test results showed, among others, that magnetic chains can neither meet the requirements for quiet operation, nor stand up to the high speeds over time. "Our linear gantries generally run 6 days per week in a three-shift operation. This calls for extremely rugged components in all areas", emphasizes Peter Vogl. "We simply cannot afford machine and system downtimes. “

"The development and design departments alone employ approximately 360 people at the Mindelheim facility", Peter Vogl reports. The total employment at the main facility is about 2,500 people. "Our order backlog is very good. We believe that we have good future prospects and are therefore once again significantly expanding our production capacity. We are also concurrently investing into our staff. The employment level will continue to increase until the end of 2012. The product spectrum of the family owned company, founded in 1926, encompasses flexible manufacturing systems for the automobile industry. This includes machining centers, special purpose machines, and the automation of these. The core competencies are machining up to a completely ready-to-install condition, including precision machining, sub- or complete assemblies, as well as inspection activities required for quality control purposes. This primarily relates to components for the drivetrain field, including engine and transmission components. With its four factories in Germany, Brazil, USA and soon also in China, the company is ideally positioned to address the local demand for its machining solutions.

Rugged energy supply systems are also employed on the pivot arm - yet another novelty.

The new linear gantry, or transfer machine, is notably more compact and smaller than the manufacturer's previous solutions. The height of the X-beam above the building floor is only approximately 3.20 m, and is therefore significantly lower than before. "Problems with building heights are a thing of the past with the new system", Peter Vogl notes. "Building cranes are no longer in our way. “

A novelty is the vertical suspension of the travel carriage, which can carry loads up to 80 kg, and that of the loading arm on large caster wheels below the X-beam. The already proven parallel kinematic technology of the loading arm was also updated and improved. The gripper can be retrofitted with a pivot axis in the A or C direction.

Yet another use for a small energy supply system. In this case, in the new pivoting gripper.

The reduction of the inert mass permits significantly higher travel speeds and acceleration. "The speed is at 6 m/s, the acceleration at 6 m/s2. The travel distance can be as much as 40m", Peter Vogl elaborates. "The speed and acceleration are therefore twice as fast as the previous model." The significantly improved dynamics of the linear gantry now permits loading of linked single and double spindle machines with a single action gripper.

A complete production line consists of a linear gantry, but also of single and double spindle machining centers for the work pieces. "Occupational safety requirements dictate that the sum of all noise is relatively moderate", Peter Vogl explains by pointing out this important requirement. This is in addition to the requirement on dynamics, wear-resistance and holding times. The P4.32 profile roller energy chain was able to prove itself from the get-go.

Michael Offner, igus® Sales Manager, Southern Germany explains: "Roller chains typically have a three to fourfold longer service life than gliding chains. “

Moreover, the partitioning of the chain links is the same with or without rollers, allowing the energy chain to attain particularly quiet and vibration-free operation along the radius. The rollers themselves are integrated into the side plates of the chain. "We made several up-front modifications to the running surfaces and to the opening crossbars, allowing us to meet the quiet running requirements under any circumstances", Michael Offner claims. Peter Vogl agrees: "Our in-house measurements show that the overall operational noise profile of the systems is at 72 dBA, which is significantly below the 75 dBA threshold permitted by several customers."

The system, which was presented at EMO, is put through its paces under realistic production conditions during on-site testing in Mindelheim.

System operators are increasingly focused on energy efficient work processes. The P4.32 (inner height 32 mm) profile roller energy chain is able to meet this challenge as well, and is consequently increasingly used on automation projects. Rolling friction is 75% lower when compared to gliding friction. This means − strictly with reference to the energy chain − up to 57% reduced drive power. In addition, due to the high push/pull forces, a gliding energy supply must be designed much stronger, whereas it can be much smaller and lighter when subject to rolling friction, without compromising speed, acceleration or noise level. "However, due to the high dynamic forces, it was apparent from the get-go that only a rolling solution would do the job", explains Roland Singer, Technical Sales Consultant at igus®. "Otherwise, the wear would be too high at these extreme forces. “

The energy supply system is provided as a pre-harnessed, ready-to-connect readychain® system , which is easily installed as a "plug-and-play" device. Especially for gantry building, the system manufacturer has been relying on pre-harnessed system solution for many years. "It makes financial sense", confirms Peter Vogl. "Throughout these many years, we have not had a single claim. " In summary, I can say that the tribologically optimized plastic chains and chainflex® cables help to design and operate machinery and systems, both, from an energy efficiency and cost effectiveness point of view.

The P4 profile roller energy chain has been historically used in crane applications, such as container handling or bulk goods loading, involving travel distances up to 400 m. Both applications rely heavily on extreme ruggedness. The noise profile is of secondary importance in these environments. This is in stark contrast to manufacturing. Here, quiet operation is essential. "But here as well, we were able to address this challenge in a partnership based, collaborative manner", Michael Offner states in retrospect. A relationship has been in place for nearly 20 years A broad range of the most varied energy supply problems were solved during this time.

This can be seen on the linear gantry in a host of technical details of the loading and automation concept. The horizontal pusher-changer, which replaces the pivot-changer for the loading and unloading process, also employs rugged plastic energy supply systems.

The newly developed loading gantry features very high acceleration and speeds, as well as highly accurate positioning, and is suited for loading work pieces with medium mass.

"These ensure the required machinery and system availability, which we guarantee to our customers world-wide", Peter Vogl summarizes. "New engine and transmission generations, and new drivetrains have been driving the increased demand for flexible and highly productive manufacturing installations with nearly all automobile manufacturers and their suppliers. We are able to address this demand with our proven systems. “

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!