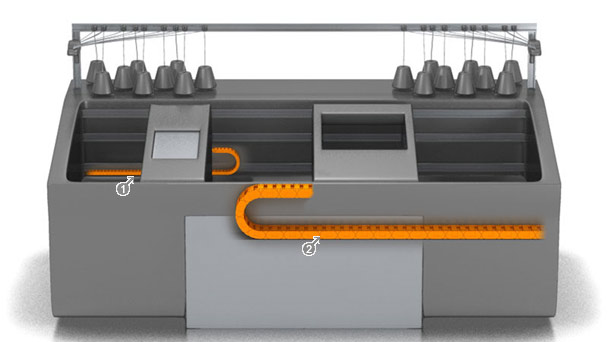

Energy chain, various cables, linear guide system

2Energy chain, various cables

Energy chain, various cables, linear guide system

2Energy chain, various cables

Socks keep the feet warm, scarves and hats protect from catching a cold. Knitwear is the focus for garment purchases primarily during the Wintertime. During the Summertime, they are used as protection from a fresh breeze.

Knitting is one of the two processes for obtaining textile, the other is weaving. While weaving consists of crossing the threads at a right angle, thus forming a textile, knitting uses at least two needles to form stitches, which then form a textile over time. The knitting process can either make a garment as a single piece, or a knitted textile can be made for further downstream processing.

Knitting techniques were already in use during the first centuries after Christ; it was regarded as a trade for quite some time, and, even today, continues to be a popular hobby that has experienced a resurgence in recent years. For example, a growing number of public knitting events are held, and knitting has even established itself as an art-form.

Of course, modern textile manufacturing no longer relies on knitting by hand. The first (initially manually operated) knitting machines came on the market during the middle of the 19th century. Today, a broad variety of textiles (garments, in-home textiles or industrial textiles, such as insulating materials) are produced on knitting machines. Equipment is classified into circular knitting and flat knitting machines.

Machine based knitting works the same way as manual knitting; it is based on the same principle. At least two needles are used to successively form stitches with a thread or yarn. When rowed together, these stitches form a textile or even a finished garment. However, instead of only two needles, knitting machines have an entire needle bed.

The many needles on circular knitting machines knit the stitches into a circular "tube" pattern; this method is used to make socks, for example.

On a flat knitting machine, the stitches hang as a row on the latch needles and are knit by means of a mobile carriage. The design of most flat knitting machines is identical. The needle bed and carriage guide is located on a base. The spool table with the rolls of yarn is located on the upper part of the machine. This video provides a good overview.

Single gauge: These machines can only work with one gauge and can therefore only process one type of yarn.

Multi gauge: As the name suggests, these machines can process several gauges. Multi gauge machines are highly flexible.

Wide gauge: Wide gauge machines can process particularly coarse knits.

Whole garment: These machines can produce nearly seamless garments.

Jacquard: This involves working two or more colored patterns into the textile.

Intarsia: This is a special technique where the pattern is visible only on one side of the material.

The textile industry is driven by quality, precision and cleanliness. This favors the use of igus® products in flat knitting machines due to their fail safe properties and the complete absence of lubricants. What could be worse than finding your beautiful garment with a lubricant stain that will not clean up even after multiple washes?

e-chains® from the E2/000 series are ideal for the carriage drive, since these are a highly reliable energy supply for the drive. The carriage guide can be implemented with precision using the completely lubricant-free DryLin® N linear guide system. Both product groups feature high speeds, abrasion resistance and quite operation. The minimal maintenance effort also limits downtimes.

igus® e-chainsystems® work ideally in conjunction with igus® Chainflex® cables. Similar to e-chains®, these can overcome the operating conditions knitting machines face in their environments, such as heat, dust from fiber residue, and chemicals used for textile processing, such as Avivage.

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!