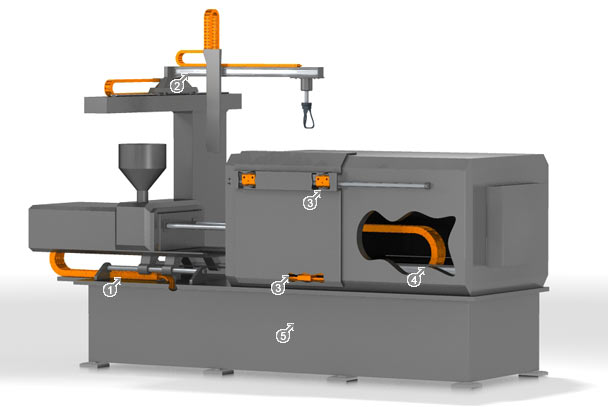

Injection molding machines generally consist of three units: the machine bed, the injection unit and clamping unit. The energy chain systems® and highly flexible igus® cables can safeguard high holding times in all the units in the plastic injection molding machine. Particularly in applications with heat generation and high dynamics, energy chains® protect cables and hoses.

energy chain®, various cables like data cables and media cables in injection unit

2energy chain®, different cables in "picker" unit

3Linear guides in sliding door of the clamping unit

4energy chain®, various cables like data cables and media cables in the clamping unit

5Machine bed

The machine bed is the base or the foundation of the machine. The switch cabinets are located here and a drive can also be integrated here depending on the machine. The other units that often can also move are located on the machine bed.

The initial part of the original forming process takes place in the injection unit. The plastic is heated and liquefied. This takes place in the so-called screw.

The clamping unit is the tool that determines the shape of the plastic product. It is called clamping unit, because the supply of the material from the injection unit can be closed and opened in the meantime. In the clamping unit are two mounting plates (one fixed and one moving) as well as a front plate. These plates are fixed vertically on one axis.