Cerion relies on tribologically optimized plastics even for the energy supply of its engraving machines. A plastic energy chain® of the series "Easy Chain®" is used to supply the workpiece table in the portable laser system "c-jet". The chain can be quickly and easily filled with cables by hand. And the larger engraving machines are equipped with the "E6" plastic energy chains®. This type series is characterized by an exceptionally quiet operation with low vibration. The polygon effect, which can occur during the unwinding of an energy supply system, is reduced to a minimum. Andreas Wienkamp: "We are impressed by the plastic material. It is maintenance-free and lightweight. " In order to save further costs, Cerion is now thinking of ordering preassembled energy chain systems® with all the bending-resistant special cables, hoses, connectors and other accessories.

Souvenirs for Paris and Rome

Plastic components reduce weight and costs in glass processingGlobal competition makes it possible: A specialist supplier of laser systems was faced with the challenge of halving the price for their machine without sacrificing the performance. Because the cost pressures, particularly from China, was immense. What followed was a complete "redesign": Many over-sized components were replaced by more economical plastic components. Since then, the demand for engraving systems is on the rise again.

"Our laser-engraving machines can be found in shops all over the world," says Dipl.-Phys. (graduate physicist) Andreas Wienkamp, CEO of Cerion GmbH in Minden, Westphalia. "For example, on the Eiffel Tower in Paris, in various Disney parks, at Madame Tussauds in London, the Trevi Fountain in Rome or in the shopping mecca "Mall of the Emirates" in Dubai. " Around 15 staff are employed at the specialist supplier in Minden. In their laser-engraving systems, it's not just the hardware, but the software for editing images is also of high importance. For this, the company provides high-performance programs and trains its clients. Moreover, a hotline has been established, which is staffed almost around the clock.

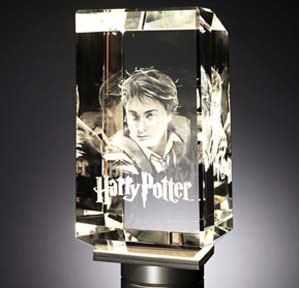

Cerion has introduced a special method for glass processing on the market. Using intense laser light, engravings can be made inside the material. The process leaves the glass surface completely intact and opens up a variety of applications. Buyers of such machines are, for instance, laser shops that make especially 3D portraits in glass in the size 50 x 50 x 80 mm or a key ring in the size 15 x 20 x 30 mm and those who rely on walk-in customers. It is important for the user that the machines are extremely quiet while working. And, secondly, that the image formation always corresponds exactly to that of its predecessor model. Joints and edges should not occur in the glass, or else it would mean the loss of quality.

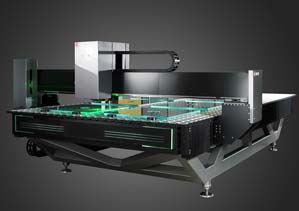

Furthermore, Cerion is currently building on a second foothold and also provides equipment for below-the-surface industrial processing. This method has advanced so much that today, glass formats in the size of 3.20 x 2.20 m can be implemented in top quality and high process speed. Designs and markings lie below the surface and open up a variety of possibilities in architectural design. Here too, the surface of the glass pane remains completely undamaged and smooth. "This method can replace conventional sandblasting today," CEO Wienkamp says with certainty.

Cerion was under extremely high cost pressure with regard to their main source of revenue, a small, portable machine for the souvenir industry. Andreas Wienkamp. "First, competing products from China are much cheaper, and second, our customers are typically new start-ups in this business model. Their investment is primarily based on the price. " The issues of reliability, holding times and service play only a minor role initially. "Therefore we had to respond urgently and significantly lower the price for our engraving system. " Additionally, ninety percent of the engraving machines are sold abroad. This means the product must be competitive and function absolutely reliably," says Wienkamp, "or we'll have to catch the next flight." “

Diverse architectural design possibilities with glass, here, for example, Harry Potter in 3D.

Portable laser engraving machine "c-jet": Maintenance-free "DryLin® N" miniature guides with polymer gliding pads are used today in the large motorized vision panel with laser protection. The "iglidur® J" polymer plain bearings are also installed there to drive the panel and in the deflection of the toothed belt drive.

The portable laser system "c-jet" enables the engraving of larger glass objects and the application of multi-mode operation for volume production. At the same time it is easy to transport, so that it can be used at fairs and other events. It attracts attention by its compact design and the large vision panel. While redesigning this machine, it was clear from the outset that no concessions could be made about the quality. Service life and reliability needed to remain unaffected. "Component by component came under scrutiny," recalls Wienkamp, "from the motor to the optics, from the guides to the laser. Gradually, the machine was redesigned from scratch. " With the result that they can now be offered at half price. Also, the overall weight could be reduced by approximately 40 kg. The demand is now rising again. Since a year, an engraving system of the model series "c-jet" leaves the production facility in Minden almost every week.

Oversized recirculating ball bearing guides were replaced by "DryLin® W" linear guides on the workpiece table in the laser system "c-jet". The maintenance-free, quiet-running system with polymer gliding pads allows maximum flexibility in design and is easy to assemble.

Larger formats, higher processing speed: The "DryLin® W" linear guides are also installed in this industrial laser system from Cerion.

"DryLin® N" miniature guides with polymer gliding pads are used today at a rail width of 40 mm in the large motorized vision panel with laser protection. They fit perfectly on standard aluminum profiles. As with all linear guides, the carriages run in anodized aluminum profiles without lubrication. It is an equally cost-effective as well as flexible guiding system. In addition, tribologically optimized "iglidur® J" polymer plain bearings are also built into the vision panel area.

They are used for driving the panel and in the deflection of the toothed belt drive. The "iglidur ® J" plain bearings are free of lubrication and maintenance and combine extremely low friction coefficients with a very long service life on many shafts.

The core of the system is the laser optics. The actual layer construction of the resulting glass product takes place here. The workpiece table can be adjusted both horizontally and vertically, which ultimately accounts for the quality of the final product. The laser lens system moves up and down during the machining process. For this purpose, a "DryLin® W" double rail and housing bearing and other individual components from the comprehensive modular system kit are used. This ranges from torque arms for added protection up to the "drylin®" trapezoidal leadscrew nuts that are very important for the engraving quality. The laser beam must reach each of the very closely overlying layers through the layer structure of the engraving. The "drylin®" trapezoidal leadscrew nuts take on these tasks successfully also in automated mode, while being impressive with a gentle operation with small spindle movements and hardly measurable wear. All components are quiet, insensitive to dirt and dust, corrosion-free and very light. Andreas Wienkamp: "The quiet linear guide systems are efficient and work so well that we now also use it in an industrial laser system. “

Energy supply system: The larger engraving machines are equipped with abrasion-resistant "E6" plastic energy chains®. This type series is characterized by an exceptionally quiet operation with low vibration.