Moving without lubricants

Tribo-optimized polymer bearings in machine tool constructionPolymer bearings are installed in machine tools and machining centres across a large range of industries. This has lead to the requirement for new developments such as the hybrid bearings for guiding sliding doors, slewing-ring bearings for moving control panels and spherical plain bearings on toothed belt drives. Polymer bearings are lightweight, robust and do not require lubrication, giving them the advantage over metal bushings. "The demands made on our suppliers are very high," reports Jörg Borgwardt, Purchasing Manager at Niles-Simmons Industrieanlagen GmbH in Chemnitz, Germany "Because of the complexity of our machines, they have to be very reliable and flexible.To achieve this, our suppliers are normally included in the design process at an early stage – usually when we have the first preliminary design." “

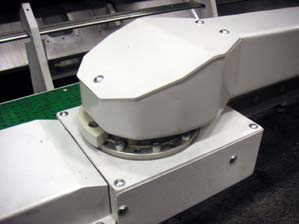

Giving machines their own face: even the control console on this machine tool from Niles-Simmons Industrieanlagen GmbH, Chemnitz, was designed by the company. It swivels easily and can be raised.

The machine builder and installer has been working together with igus® for a number of years now. Many different products based company are installed in the machine tool and machining centres from Niles-Simmons. In addition to the custom made polymer energy chains, they use the "DryLin W", a linear guide with polymer gliding elements which are mounted in the machine space using movable rails. In addition igubal® spherical bearings are used, as well as hybrid linear bearings and polymer slewing ring bearings in various auxiliary movements. The igus igubal spherical plain bearings are also playing an increasingly important role in the new designs. The international company Niles-Simmons Industrieanlagen GmbH has concentrated its business activities in the field of research, development, production and sales of machine tools. According to Pierre Seildel, the marketing manager, the company’s product philosophy is that "Our goal is to manufacture and globally market products of the highest quality”. About 350 people are employed at the company headquarters in Chemnitz, but within the entire NSH Group, there are over 1,100 employees throughout the world.

Lubricant and maintenance free slewing ring polymer bearings are used to move the control console. The low friction values ensure that little force is needed to swivel the unit.

The product range is based on six machine designs, divided into the fields of aerospace, automotive, railway and general machine tool construction, as well as tool and mould construction.Typical products are horizontal CNC lathes, CNC lathing-milling-drilling machining centres, as well as high precision milling centres .In addition, the company does the planning and construction for complete assembly lines for the automotive industry as well as for workshops for the repair and production of railway bogies as part of the NSH Group. The modular design and ability to accept additional drive systems, means the machines can be set up and produced in accordance with the specific requirements of the customer work pieces. "Our machining centres for all work piece sizes, have a compact, very ergonomic and easy to use design. In addition, we offer excellent service and easy maintenance," says Pierre Seidel.

Niles-Simmons has now started relying on "iglidur" polymer slewing ring bearings which need neither lubrication nor maintenance to move its control consoles. The cantilever arm system for the control consoles used to be delivered as a complete unit from one supplier. "However, we wanted to give our machines their own face," reports designer Jens Liebscher. "Therefore we decided on the design of our own control console which looks good with the machining centre it is used with." ." It needed to rotate easily and we wanted to make it possible to raise it as well. Two polymer slewing ring bearings installed as a complete unit are used in the newly designed control console. The polymer gliding elements are made from a material called "iglidur® J". In addition to its main purpose, freedom from maintenance and lubricants, the slewing ring bearings are highly wear resistant. They also have a low coefficient of friction which ensures little force is needed to swivel the console.

"Our control consoles are removed for transport,"

says Jens Liebscher. "Since it is a complete unit with the slewing ring bearings, installation and removal are much faster. The time factor also pays off when it comes to installation. We do not have time to put the entire bearing together from individual parts. Today the module is just screwed on and is ready to use. " In the case of the control console just described, a special bearing from igus is used. "We adapted the design to the requirements of the customer," stated Thomas Sommerweiß, Technical Sales Consultant from the igus® office in Saxony, Germany." "If, for example, someone leans on the control console, then that puts a lot of torque on the bearing. Fortunately, the slewing ring bearing allows much higher loads in such cases. This increases customer safety." “

Sliding magazine doors in machine tools or machining centres: customers today do not want them to move too easily. But at the same time the force needed to open then must not be too great.

Another example for a tribologically optimized polymer solution is the innovative hybrid linear bearing from igus for the secure guiding of sliding doors. All machine tools or machining centres are equipped with sliding doors. The housings are completely removed for transport, including all the guides, and then reinstalled at the customer's site without a great deal of adjustment. "However, the customer does not want the sliding doors to move too easily. At the same time, too much force should not be needed to open them." For these subsidiary movements, hybrid linear bearings really show their strengths. They cannot twist, but remain free of both lubricants and maintenance.

Innovative hybrid linear bearing (centre of image) to guide sliding doors. The main load lies on the roller bearing which reduces the drive force needed. The polymer glides absorb any lateral forces.

The new "DryLin WJRM" hybrid linear bearing from igus reduces the force necessary, especially for manual doors, protective doors, sliding doors, and lock adjustments. They combine the specific advantages of gliding and rolling movements.

The main load lies on the roller bearing, which reduces the drive force required. The polymer glides absorb any lateral forces. The main weight from moving this work door lies on the roller in this application. In addition, there is very little space available to install it. The hybrid linear bearing is only 18mm high.

It is used as a single rail in the sliding magazine doors. The aluminum profile, which is part of the system, pays off when changes are made. It is easy to modify, mounting holes can easily be made.