Sometimes our customers require custom parts or services, and for many years this has been an important part of the igus® support

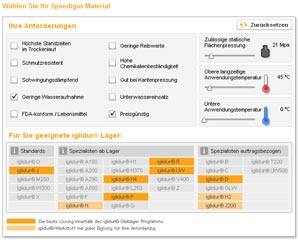

Now, with speedigus®, we combine custom parts with speed, using the benefits of igus® tribo-plastics.

speedigus® custom parts can be manufactured in three distinct ways:

speedimoldThis is where a 3D model from the customer is used to produce a fast aluminium injection mould tool, allowing real igus® parts to be manufactured very quickly. The leadtime for this service varies from 24 hours to a maximum of three weeks.

speedicutThis is where the igus® stock bar is used to machine a custom part to a 2D drawing or 3D model. The leadtime for this service varies from 3 days to a maximum of three weeks.

speedifitThis is where an igus® part is fitted into a custom housing or unit, and the whole assembly is supplied as one part. The leadtime for this service varies from five days to three weeks.

All speedigus® options have the same promise: On time delivery and 24 hour response for all enquiries.

Extended: speedigus®

Customized bearings parts

Available from summer 2015 also as iPad app for iTunes.

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!