"The technical consulting paid off from the very start"

Smooth-running energy supply systems for multi-spindle machining centerThe direct drive technology has strongly established itself in machine tool construction. Auxiliary process times and set-up costs lower further and the processing speeds increase. After appropriate consultation on site, a company with long tradition equipped its two-spindle horizontal machining center with especially low-noise, low-vibration energy supply systems, which copes with the technical requirements on dynamics and acceleration without a problem.

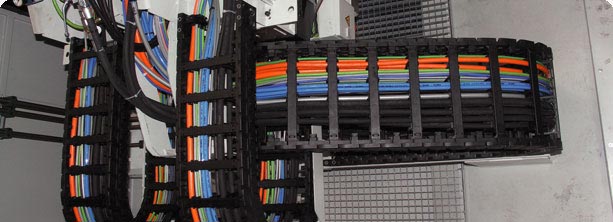

In almost all horizontal machining centers and special machines of the company, energy supply systems perfectly aligned to every design requirement have been used since several years. The variety of electrical, hydraulic and pneumatic as well as the data cables must be accommodated neatly, logically and in a space-saving manner.

In the event of the linear machine, Mr. Yve Kirsch, the sales consultant of the igus® GmbH in the Thuringen office, recommended the energy supply system of the type E6. They display their specific strength especially in high-speed axles. The two-spindle horizontal machining center with linear drives in all axles poses high demands on the used E-Chain®. Besides the cables, they should always safely cope with speeds of the axles of 100 to 120 m/min, accelerations of 1 to 1.5 g, spindle rpm-range of 50 to 15,000 per min-1 and travels of 450 to 630 mm.

The ambient conditions for the energy chains are not particularly difficult compared to applications in other industries. Simply the most varied types of coolants come into contact with the E-Chains.