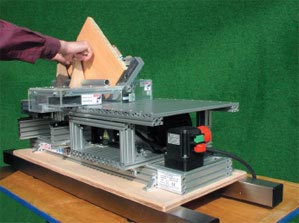

The application is a new machining process for furniture production. Until now complex corner-contours on furniture pieces were avoided due to the high technical costs. In the manufacture, the projecting, thick or sharp edges at the ends were often trimmed with the broach and subsequently rounded by the cumbersome hand grinding. In the new process, the trimming and rounding is done by a single rotating tool. The result is clean and precisely formed cut surfaces.

For this purpose, a DryLin® linear guide system is used. The manually moved feed carriage moves in all positions against a constantly higher friction force. With it the workpiece can be pressed against the vertical system without any other agent and are safely tightened. Due to the low friction in the use of roller bearings, a complex counter force or gripping mechanism is necessary.

Dr. Christoph Heßler, Dr. Christoph Heßler

Maschinensysteme, Luebbecke