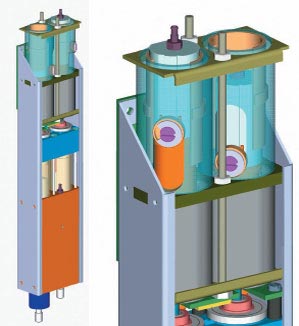

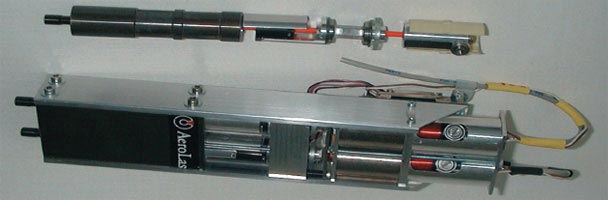

This novel insertion head (pick & place) for circuit board machine uses DryLin® liners.

Every unit has its own drives for rotary and stroke movements. That enables the simultaneous recording of all components found on the pipettes by means of a camera during the run of the insertion head from the component dispensers to the blank. The separate drives enable an alignment of the components "during the travel" that results in an optimization of the cycle time.

Due to the variety of drives used in the insertion head and measuring systems in limited installation space and dimensions, the integration of the components at the highest level was important. The linear movement was implemented by means of plunger coil motors, whose rotors are seated in igus® liners. Besides the guiding function, the open design of these liners allows the simultaneous affixing of the scale for the position measuring system and an anti-twist device for minimum installation space. A conventional design with separate guide for linear motor, measuring system and anti-twist protection would have meant an enlargement of the installation length by about 20%. As up to eight of these units are mounted side by side in an insertion head, the saved weight is also substantial.

Jan Brand, AeroLas GmbH, Unterhaching