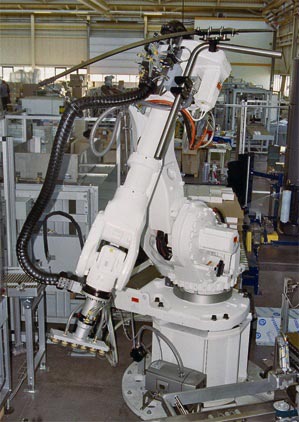

Energy chain for flexible palletizing robot

The motion sequences of the palletizing robot are complex,Up to 17 different formats are processed with the Skinetta packaging system – and at high speed. Generic drugs in this case, filled in glass bottles of 2 to 100 ml. Up to 350 glass bottles of 2 to 100 ml can be packed in cartons per minute.

Several minitoring stations are integrated in the production line, partially with camera systems. In case of irregularities

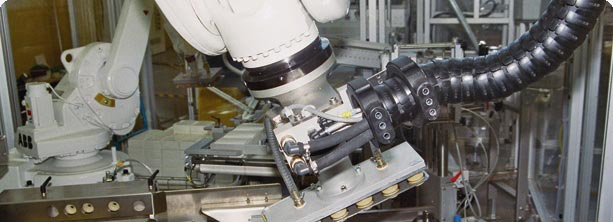

the robot places the carton on one of the extraction points, which increases yet again the movements and operating ranges.The design engineers decided on the Triflex® R energy supply system, in which the vacuum cables for the gripper are also integrated besides the energy and control cables. For the precise guidance of the chain, the igus® accessories kit was also used.

No loop formations

To optimize the motion sequences of the chain

a 90° angle tube is mounted on the fastening points of the robot. A spring element is mounted on the required position on this tube. The required pullback movements are initiated over a cord connection between the spring module extension and the Triflex® R. The movement of the chain in the pullback action of the robotic arm can be multiaxially guided over the position of the fastening tube. Thus the loop formations at the robot's wrist or friction against the robotic arm are avoided.