Pivot and oscillate under pressure

High-performance polymers in wood workingWood dust, high pressure and high temperatures: The environmental conditions of the bearings in the machine that assembles wood veneer are all something other than ideal. The polymer bearings from igus® have proved themselves under these extreme requirements. The Kuper GmbH, as the only manufacturer who covers the entire spectrum of veneer jointing technology, employs split iglidur® G bearings at a particularly critical position in a new generation of machines – the pressure bar bearing.

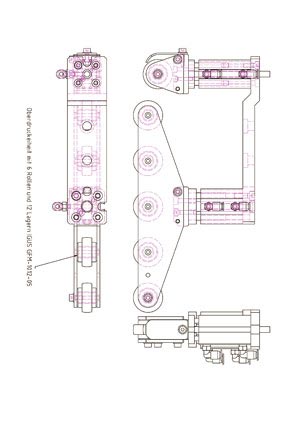

The environmental conditions pose very high demands on the bearing of the bar for the designers and, as a consequence, for the users of the machine. Ultimately, the bar must withstand, besides its own weight, the high pressing forces of up to 20,000 N. This demand is, among others, not at all easy to fulfill, as the bar may bend under pressure loads. One of the tasks of the bearing points is to compensate the bending. In order to allow for good accessibility, Kuper provided a rotary motion for the new machines: The pressure bar can move toward the operator by 90°. And one searches for new ways for the bearing of the pressure bar: Polymer plain bearings are used, the iglidur® G bearing of the type GFM 90-95-100 to be precise, which was split and shortened to the length of 60 mm. This solution proved itself in practice: By the rotary motion, the adhesive elements directly turn toward the operator and are therefore well accessible for cleaning and maintenance purposes. The installation and dismantling of the pressure bar is very easy due to the splitting of the bearing, and the clearance of the iglidur® bearings very effectively compensate for the thermal expansion and bending under loads of the pressure bar. In the process, the bearings and/or the bearing materials do not come to their load limit even once: The application of iglidur® bearing permits clearance upward, so that larger working widths till 4000 mm and loads up to 25,000 N are possible. The application of the iglidur® G bearing is the first choice for Kuper in this case due to the corrosion resistance and the insensitivity to the copiously arising wood dust. The maintenance-free dry operation of the iglidur® bearing is guaranteed by the "integrated" lubricant: The lubricant is permanently incorporated in the materials matrix, so that oil or fat need not be subsequently administered throughout the service life of the bearing, and the bearings operate dry despite the exceeding coefficients of friction - an indispensable feature in the dusty environment of veneer production.

Plastic plain bearings in veneer jointing machine

Only a negligible plastic deformation has been measured in iglidur® G bearings at surface pressures of up to 100 MPa. This high compressive strength also figured among the demands posed by Kuper for the pressure bar bearing. The bearing is also therefore suitable for the absorption of high pressures, because the coefficient of friction decreases with increased load. Last but not least, not only the technical data , but also the economic data adds up: iglidur® bearings are, in comparison with standard metallic roller bearings and of course also with ball roller guides, distinctly economical. At the same time the service expenditure is minimized, because the bearings are maintenance-free and offer high holding times: Even with high loads, constant coefficients of friction are attained in long-term applications.