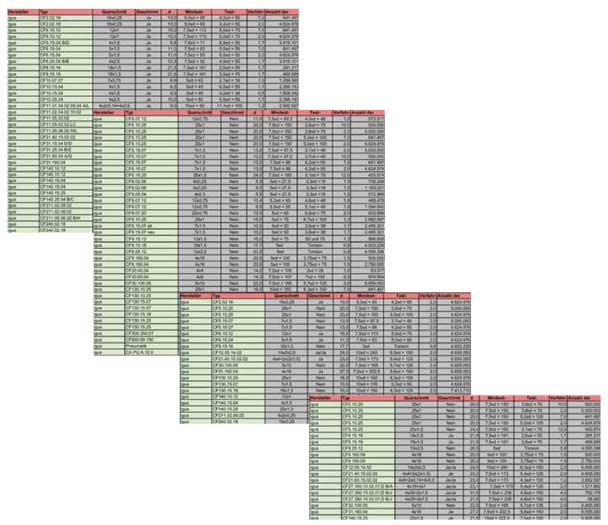

Example 6: tested! Selection from test results

Since 1989, we have been working on the development of electrical cables.

Back then, many of our customers lost their faith in the solution with energy supply systems because the cables being used frequently failed. Core breakage, "corkscrews", jacket wear and breakage of the shields were substantial reasons for these failures.

Our Chainflex® product range was then created from this situation of emergency. And due to the fact that we knew very little about cables at that time, we had only one choice:

Testing, testing, testing, testing, testing.

We almost always test our cables with a bending radius that is 30-50% less than the bending radius we mention in our catalog. We guarantee the quality requirement specified for our own products based on the production-process-accompanying sample tests that are carried out with at least 1 million reverse bending processes. During the subsequent inspection of the cable, this cable must be completely intact and, especially, none of the single wires must be broken. Newly developed types undergo considerably longer reverse bending processes in Energy Chains® before a new Chainflex® series is released.

Selection of test results from the igus®-own technical training center in Cologne for the year 2000.

Today, we have recourse to an extensive database with detailed information on the service life of our Chainflex® cables which makes it possible for us to give you the information you need for your application.

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!