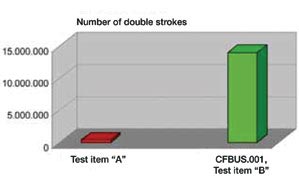

Differences in service life

At the beginning of 2002, a test to determine the service life of profibus cables in a real application was commissioned in

igus’ test laboratory. The aim was to examine any differences

in the service life of igus’ CFBUS.001 Chainflex® cable

and another market leading profibus cable. The parameters

required for the test were selected on the basis of data contained in the competitor’s catalogue:

| Catalogue details |

Test item “A”

Twin-core

profibus cable |

Test item “B”

igus® Chainflex®

CFBUS.001 |

| |

| Cross section |

(2 x AWG24)C |

(2 x 0.25 mm2)C |

| Guaranteed lifetime |

Min. 4.0 Mio. Cycles |

To be determined in

a test |

| Bending radius |

> = 60 mm |

85 mm |

| Diameter |

8,0 mm |

8,5 mm |

| Catalogue details |

as in 2002 |

as in 2002 |

Test parameters according to catalogue data of the competition

A gliding application was chosen as a suitable test structure

since profibus cable systems are usually used here because

of their data integrity, particularly over long lengths of travel

and long transmission distances.

In order to be able to carry out non-destructive testing and

hence achieve a large number of bending cycles in a short

period of time, a genuine profibus transmission path was

erected. In a PC at the fixed end of the test chain there was

a profibus master insert card. A connection to a profibus slave

was located on the moving end. This enabled the transmission

rate to be determined with the help of a diagnosis program.

Any data packets which might have been transmitted

incorrectly could be indicated. The highest-possible transmission

rate of 12 megabits/s was set.

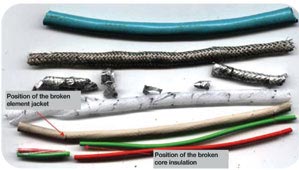

The fundamental test, which commenced at the beginning

of 2002 and is still in progress today, showed that only a

relatively low number of cycles (420,000) resulted in the total

failure of test item “A“, which, according to the competitor’s

catalogue, should have functioned safely for at least 4.0

million cycles. The actual service life achieved deviates from

that indicated in the catalogue by a factor of ten.

On the other hand test item “B“, the CFBUS.001, is still undergoing

testing without any faulty data transmissions.

So far, it has accomplished more than 14.0 million cycles.