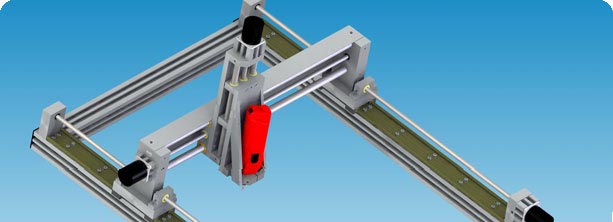

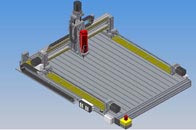

The two students, Markus Fey and Joachim Schrott, have almost completed their four-year advanced study at the technical college for automation technology at Mainz. Their advanced course ends with their final practical work. The assignment of the Mainz technical college was to design and implement a CNC-controlled three-axis machine in portal design.

DryLin® R

3Trapezoidal leadscrew nut

8Guide rod

16DryLin® R

19Guide rod

24Rail

25DryLin® W