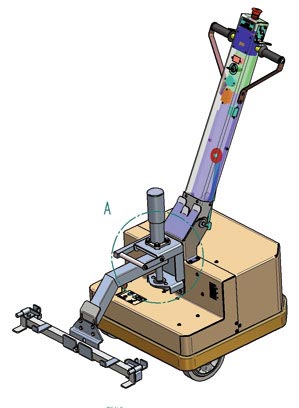

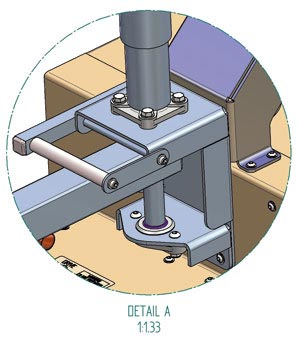

Pulling arm of an electric tug

The electric tug is used for various applications, but mainly supermarket pallet moving. The arm’s vertical and rotational movements allow the tug and pallet to maneovre. The tug is subject to high loads and must run smoothly. The original design used fixed oil filled sintered bushes. The ratio of the arm pivot length to the bearing spacing was close to 2:1 and the bearings were sticking. The sinterered bearings were substituted with spherical flange bearings from igus®. These eliminated the need for precise bearing alignment, which was difficult to achieve due to the nature of the assembly. The igubal® bearings enable smooth running, have a high load capacity and there is relatively small force required to move the arm.

Paul Japheth

Project Engineer

Denis Ferranti Group / Dalynn Designs