Bicycle shock absorber with combined bearing shaft

With rear wheel bicycle suspension systems, a shock absorber, similar to that found on automobiles, is fitted between the unsprung rear wheel assembly and the sprung main bicycle frame, thus isolating the rider from road vibrations. Bicycle shock absorbers are generally comprised of a cylindrical metal shaft that slides linearly inside a cylindrical metal outer shock body. In order to function safely, effectively and still be durable, special low friction bearings are fitted between the oscillating shaft and the outer shock body. These bearings allow the shaft to slide smoothly without wearing out the shaft surface and the bearings also keep the shaft aligned correctly within the outer shock body. Similar low friction bearings are fitted to the end of the shaft and to the end of the outer shock body where the shaft and outer shock body are fixed to the bicycle frame. During normal operation, these end bearings, or bushings as they are commonly referred to, allow the shaft and outer shock body to oscillate rotationally and in a single plane relative to the bicycle frame without excessive wear of the shaft and outer shock body. The problem with traditional shock absorber design is that the many parts required to make them both lightweight and durable have a relatively high manufacturing cost. Karbon Kinetics realised a novel solution to making a lightweight and low manufacturing cost bicycle shock absorber would be to reduce the number of parts by combining the low-friction bearings, end bushing bearings, and the sliding shaft into one part.

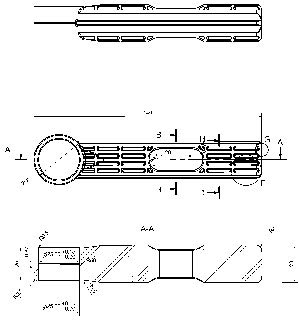

The resultant inventive combined bearing shaft is manufactured in a single part from the igus® iglidur® RN56 polymer, which exhibits both high strength and low-friction properties. The design and geometry of the combined bearing shaft have a largely cylindrical design made possible by a webbed construction and making it suitable for igus® to injection mould at low cost. The outer shock body of the invention exhibits a unique, low cost manufacturing clam shell design of a left and right side fastened together around a metal tube. The benefit of this novel clam shell outer body design is a more visually appealing shape, whilst still offering low manufacturing cost and safe, functional operation. It also enables the efficient transmission of load forces from the combined bearing shaft to the spring member contained in the metal tube and to the outer shock body fixed to the bicycle frame. Further to this, the nature of the design enables the combined bearing shaft and outer body to be separated. This can be a benefit when the shock absorber is fitted to foldable or demountable bicycle frame designs. An additional novel and inventive feature of the combined bearing shaft and outer clam shell body is the benefit of being able to lock the separable parts together by inserting a pin, such as that found on a standard bicycle lock, through a uniquely positioned hole in the combined bearing shaft and a corresponding hole in the outer clam shell body.

Richard Thorpe

Managing Director

Karbon Kinetics