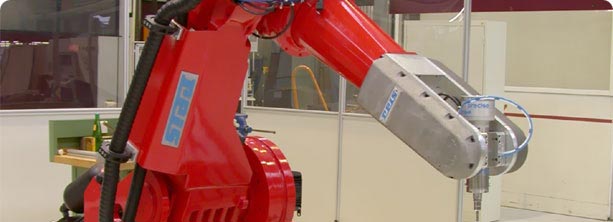

Surface works on large, difficult to access workpieces are often executed by tedious manual work. The project ADVOCUT (aided by the German Federal Ministry for Education and Research) wants to change that. In future, easy milling tasks should operate fully automatically. ADVOCUT is designed for the serial application, for instance in the spare parts production. Thus companies can organize processes that are intensive with regard to costs, personnel and time in an essentially economical way and save time and money on a long term.

Emphasis of the research and development works of the student team is the maximization of accuracy. "No easy enterprise," declares Michael Kulok, staff of the Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen at the TU Darmstadt. He is however convinced that an efficiently operating machine will be developed before the end of the project in September 2006.