DryLin® T linear guide systems always require a minimum clearance between carriage and rail. They are supplied with pre-adjusted clearance ready for installation. For special requirements, please state whether you require an especially narrow or an especially broad clearance. The bearing clearance of the carriages can also be adjusted later if necessary. This should be done without additional load.

DryLin® T - Clearance adjustment

Lateral guide:

- reduce clearance, + increase clearance

Vertical guide left

Vertical guide right

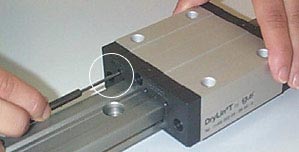

After removing the protective cover, loosen the locknuts. Width across flats:

SW 5 for TW-01-15 and TW-01-20

SW 7 for TW-01-25 and TW-01-30

Reset the bearing clearance for the 3 guide points with an Allen wrench. Width across flats:

1.5 mm for TW-01-15 and TW-01-20

1.5 mm for TW-01-25 and TW-01-30

After the adjustment, check the clearance of the carriages. If it is adequate, tighten the locknuts and attach protective cover.

In case the clearance has been set too close so that the carriage seizes, it is not enough to reset only the Allen screws. After screwing them back, additionally operate the reset button on the opposite side of the screws to release the gliding elements again. Use a pin of the following size for this purpose:

1.5 mm for TW-01-20 and TW-01-15

3.0 mm for TW-01-25

3.0 mm for TW-01-30

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!