Strain Relief Devices

Strain relief devices for energy chains®

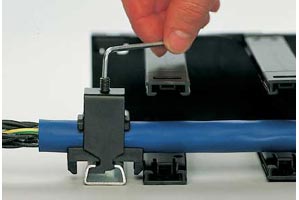

KMA connection element with integrated C profile and Chainfix

igus® Chainfix reduces the overall height due to optimum housing height

Long-term durability for dynamic applications due to improved press-fit elements

Suitability for integration in the KMA connection element

Space-saving and time-saving assembly

Possibility of delivery for complete systems with cables and assembled strain relief device

Improved foot for facilitated installation on the C profile

Easy installation of the strap clip due to improved foot

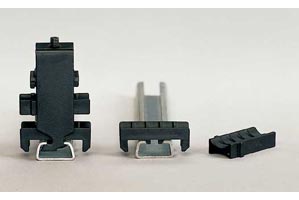

Characteristic features of the igus® chainfix strap clips

Optimized height due to newly developed housing

Improved foot for facilitated installation on the C profile

Good visual effects due to black housing body and black threaded setscrews

Easy to assemble due to setscrews that are screwed using an Allen key

Reduced overall height due to setscrew and optimum housing height

Characteristic features of the igus® press-fit elements

Long supporting surface improves the stability of the strap clip

High inherent rigidity increases the operating safety

Integrated ribs prevent the cable from detaching itself from the strain relief device

New pressure trough, mating trough and press trough with ribs for better long-term durability

Overall height

When the energy chains® glide along on themselves in the case of long distances of travel, the screw heads of the strain relief device at the fixed point of the chain must possess a separating distance of at least 10 mm to the top edge of the energy chains®. Our newly developed clip housing with setscrews reduce the overall height by as much as 15 mm compared with conventional strap clips.

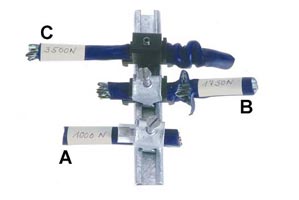

Three times higher tensile strength than with standard-type strap clips

We tested three different strain relief devices

a. A. Standard-type strap clip made of hot-galvanized steel, double trough and press trough made of impact-resistant plastic (Art.no. CF14.1.Z, standard elements)

B. Strap clip as described above, double trough and press trough made of igumid G (Art.No. CFY14.1)

C. Strap clip "Chainfix", mating trough and press trough made of igumid G (Art. no. CFX14.1)

Three times higher tensile strength than with standard-type strap clips

Standard-type strap clip

igus® Chainfix strap clip

igus® Chainfix stainless-steel strap clip

At 1,000 N, the strain relief device A is pulled out of the strap clip by the cable. The inclined position results in the immediate destruction of the screws and strap clip.

From 1,000 N onwards, the strain relief device B moves into an inclined position (10°). At 1,750 N, the cable is squeezed to such an extent that the jacket "peels off".

At 1,750 N, the strap clip of the chainfix strain relief device moves into a position inclined by 5°. From 2,500 N onwards, the cable starts to jam up behind the strap clip and then becomes useless from 3,500 N onwards.

The tensile strength of the strap clip Chainfix developed by igus® is three times higher than the tensile strength of standard-type strain relief devices.

Your contact

Theo Diehl +49 6162 6808 Your requirements?

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!