... innovative machine elements from igus®

3D printer manufacturer uses ready-to-install system solution

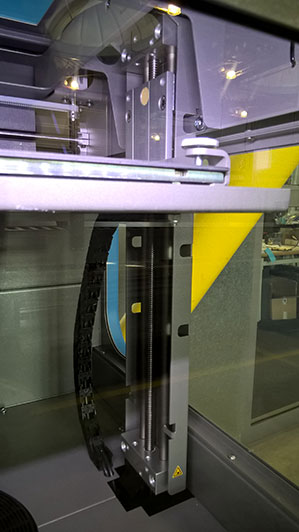

Whether in rapid prototyping or mass production - the 3D technology offers fascinating opportunities.In addition, the igus® energy chains ensure the safe guidance of the connecting cables in the computer-controlled printing process. Due to their low installation height and narrow bending radii, the micro chain series for dynamic applications are especially suitable for tight installation spaces in 3D printers in every direction of movement. Like the linear plain bearings, the micro chain series also have a very low weight. The chainflex® control and motor cables guided therein are especially designed for continuously moving applications and prevent cable failures and thus guarantee a long service life for the 3D printer. Combined with motorised drylin® linear axes, which include motor flanges, couplings and drylin® E stepper and DC motors, igus® can supply a completely ready-to-mount operating unit from a single source. [EVO-tech GmbH]

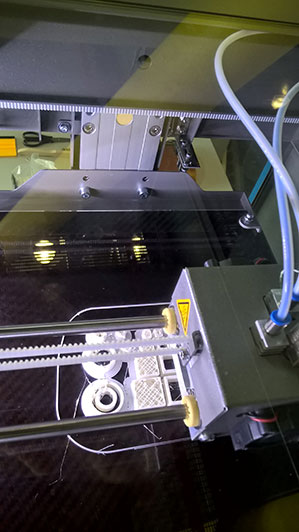

In addition to the quiet operation, the quality of the objects produced is important for professional use. For example, lubricants can contaminate the raw material or the printed product. Made from high-performance polymers, the plain bearings from igus® dispense with lubrication due to the fully integrated solid lubricants. The risk of contamination is thus avoided. The dry operation also makes 3D printers maintenance-free and increase their operational reliability. For the moving components in 3D printers, factors such as acceleration and positioning accuracy play a role in the reproduction of the product detail. The smooth-running drylin® linear plain bearings and lead screw units can be used in both slow and high accelerations regardless of the travel path.

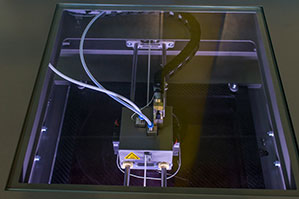

igus® uses the Evolizer for the 3D printing service.

(from l to r) Tom Krause (igus®), Markus Kaltenbrunner (EVO-tech GmbH), Michael Hornung (igus®)

Durable and smooth-running e-chainsystems®

Ready-to-install drylin® SLW linear module for the height adjustment of the z-axis

Lubrication-free and low vibration drylin® R round shaft guides