3D Printing machine

Cheaper printing

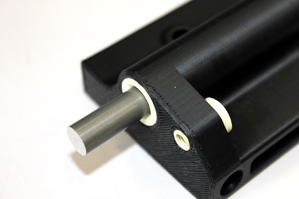

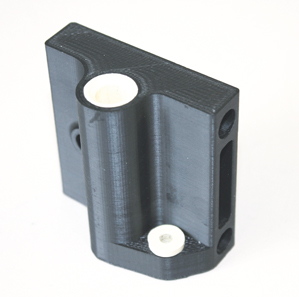

This idea could significantly reduce the purchasing price of 3D printers for private use. Usually, the guides in this printers use linear ball bearings or bronze plain bearings. This is impractical, since the bearings have to be lubricated regularly to work perfectly. Since the printer components are printed in 3D, the idea was born at Bern University of Applied Sciences to print the plain bearings directly where they are required. Innovative igus® Tribo-Filament was used for this purpose. It is up to 50 times more wear-resistant than conventional 3D printing materials. The result: more favourable production costs plus greater rigidity and precision of the printer thanks to the direct integration of plain bearings in the components.

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!