A customer is constructing a solar energy system, where its moving solar panels follow the sun. To identify a suitable pillow block bearing for the pivoting movement of bearing points, the application was reproduced on the universal test bench in the igus® test laboratory.

The goal of the test series was to determine for the customer the most wear-resistant pairing of shaft and iglidur® material.

The test was carried out under the following test parameters:

Shaft material: V2A steel and galvanised steel

Bearing: igubal® pillow block bearing with spherical balls made of iglidur® W300, J, and J4

Load: 5 MPa

Pivoting angle: +/- 75°

Cycles: 30,000

Speed: 10 cycles/min

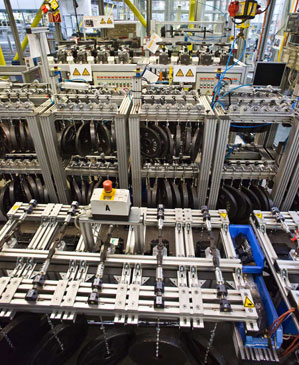

igubal® pillow block bearing ESTM

igubal® pillow block bearing ESTM