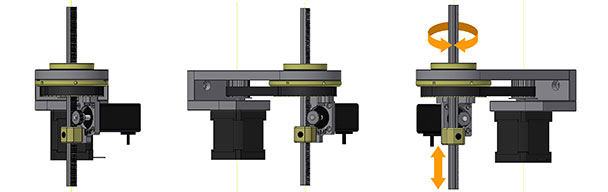

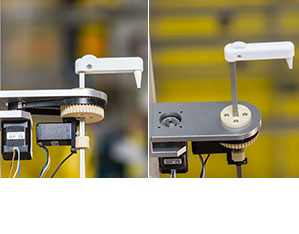

The new compact drylin® lift/swivel unit is based on a rack and pinion drive with coated aluminium 4-edge profile and a round table element with integrated toothing for holding the belt. The mounting of the two directions of movement is done with bearing elements made of iglidur® high-performance polymers, which are completely free of lubricants and maintenance. The combination of plastic and aluminium ensures an extremely easy construction and can be configured, ready for installation, with the drylin® E stepper motor technology.

The new lubrication-free drylin® lift/swivel unit for laboratory and analysis technology*

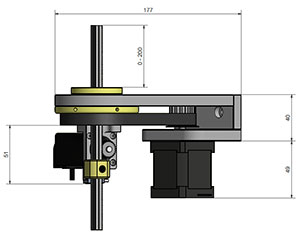

drylin® lift/swivel unit for laboratory and analysis technology (design study)

lift/swivel unit details

Weight savings and greater dynamics through plastic and aluminium

Lubricant-free and maintenance-free operation

Compact construction, modular design

4-edge profile with hollow chamber suitable for supply cables and media

Supplied ready to install with NEMA stepper motors

Very low noise and affordable prices

Application areas for the lift/swivel units are pipetting and analysis machines in medical technology, or in the bio-chemistry, or in the handling of lightweight components. Wherever samples are analysed and evaluated, the new drylin® lift/swivel unit offers a lubricant-free and cost-effective alternative to conventional systems with recirculating ball bearings.

Preliminary technical data:

Max. axial load: 300 gr.

Max. speed

Linear: 0.5 m/s

Pivoting: 0.4 m/s

Max. stroke length: 200 mm

Max. pivot angle ∞ (depending on the energy supply system)

Recommended alignment of boom arm: 90° to the toothing

Toothing HTD-5M, toothed belt Neoprene 9 mm width

Transmission ratio 3:8

Scope of delivery:

Lift/swivel unit, mounted on plain bearings made of iglidur® J, 4-edge gear rack made of hard anodised aluminium. Flange fixtures in anodised aluminium, NEMA11/17 stepper motors mounted

Optional: Stepper motor with encoder, freely positionable initiators

Lift/swivel unit in action: presented for the first time at the Compamed fair in Düsseldorf from 12 to 14/11/2014

*Study as of November 2014, expected to be available from April 2015, technical changes are reserved, boom arm not included in delivery.

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!