Short linear stroke against various shafts

The wear of iglidur® bearings in short linear strokes is to be tested. Among others, this involves analysing very short linear motions of 5 mm at high frequency, such as occur in actuators and in solenoid engineering. The intent of the test series is to determine the most wear-resistant iglidur® plain bearing material on various shafts for short linear stroke motions. An additional objective of the testing: wear rates for the service life calculation in the Internet (iglidur® expert).

The wear characteristics vary from iglidur® material to iglidur® material on different shaft/counter partners during the testing. The results show that iglidur® materials operate with lower wear on hard-anodised aluminium versus mild steel (St37). It is worth noting that each shaft material has a matching iglidur® material that optimises wear, and vice-versa.

Wear results are available for all iglidur® materials against various shaft materials. The chart only shows an excerpt. Please contact us if you are interested in the results of other pairings.

We will gladly test your specific application as well. Simply use the contact form on the back!

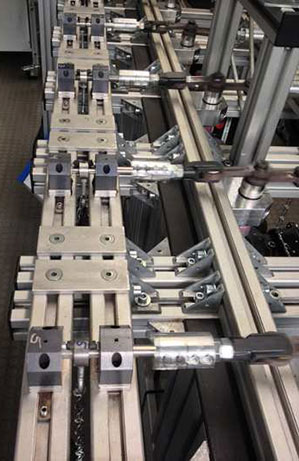

dry-tech® test lab

igus® develops polymer materials that solve new bearing tribology application problems. Base-polymers, solid lubricants and reinforcements are combined in such a manner that the desired bearing properties are attained. These are validated in lab-tests based on practical experience in order to optimize the materials.

These tests validate the bearing system consisting of shaft, bearing and ambient conditions.

In the dry-tech® test laboratory about 135 trillion test movements are conducted every year.

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!