igubal® spherical bearings

igubal® pillow block bearings are self-aligning bearing elements completely made from plastics. The split and self-aligning pillow block bearings are easy to assemble, adjust to all angular variances, and in many cases were already able to replace special housings. The igubal® user utilizes all advantages of the employed high performance plastics. They have excellent vibration dampening properties, and are technically applicable in dry operation. They are insensitive to dirt, can operate in liquids and even in chemicals and are completely resistant to corrosion. The weight of igubal® parts is up to 80 % lower than for comparable competitive parts made from steel. Additional savings are obtained for costs incurred during the procurement and maintenance phases. igubal® products are extremely competitive because of the reduced maintenance and repair costs, and due to the faster assembly and disassembly of the split design. Moreover, installation space can be reduced due to the smaller dimensions. igubal® self adjusting spherical bearing consist of fibre-reinforced plastic housings for high stability, and spherical balls made from tribo-optimised high-performance polymers for reduced wear and long service life. Type series igubal® gives developers access to a complete system of self-adjusting bearing elements: rod end bearings, clevis joints, flange bearings, spherical bearings and pillow block bearings.

1... Part weight

lower moving loads

Because all igubal® spherical bearings are made from polymers, the part weight is up to 80% lower than for a comparable metallic bearing. Accordingly, e.g. less mass needs to be moved, resulting in reduced energy consumption.

igus® tested

Application example

A novel external load system for helicopters required a low weight, high reliability with simultaneous weather resistance and freedom from maintenance. Therewith rescue operations such as a flood evacuation are possible.

2... Outdoor use

Corrosion-resistantDetails of working principle

The corrosion resistance of the igubal® bearing elements make them particularly suitable for outdoor use. igubal® bearing element can also be used without any problems in tough environments. Even under extreme dirt accumulations, the igubal® bearing elements manage without sealing. The same applies for fine dust or rough dirt.

igus® tested

Application example

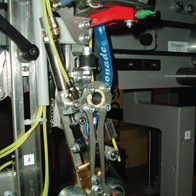

The rod end bearings remain maintenance-free even when the environment is stressed by fine dust or abrasive pollutants. There is no danger of fretting or jamming, and the integrated solid lubricants provide for low friction with extreme abrasion resistance.

3... Vibration-damping

reduces vibrationsDetails of working principle

The use of special plastics as the housing material and also for the bearing spherical ball make igubal® spherical bearings an ideal component when increased vibration damping is required. Longer service lives can frequently be achieved by using igubal® spherical bearings, particularly on applications with high-frequency oscillations and vibrations.

Application example

Endurance test of one year with 97 million cycles at 15,000 cycles per hour Operating time of approximately 6,500 hrs. Inner diameter after the test: 6.0 light - 6.1 jams Load between 50-90 N Steel failed after approximately 50 million cycles

4... Shaft diameter

16mm …. 50mmDetails of working principle

igubal® spherical bearings are available for shaft diameters from 2mm to 50mm as standard components from stock.

igus® tested

Application example

In these pool covers (above-ground facilities) ball bearings were used in the past. Depending on the size of the swimming pool cover, igus® igubal® flange bearings of the EFSM series are now used.

5... Lubricant- and maintenance-free

No maintenance requiredDetails of working principle

By avoiding lubricants and oils, there is no risk of gumming, or the formation of a paste-like mixture. The lubricant incorporated into the tribologically optimised plain bearing materials also ensures uniform lubrication for the entire service life.

igus® tested

Application example

In the packaging plant for profiles, around 50 tribo-optimized polymer bearings prove their strength in the most varied positions. These are flange bearings and pillow block bearings for pivoting and rotating movements as well as various rod end bearings which absorb traction and pressure. About 50 spherical bearings of the "igubal®" type series are mounted on each packaging unit.

6... Splitted design

Easy assembly and disassemblyDetails of working principle

igubal® pillow block bearings are available from installation size 16mm to 50mm in a fully split design. The split of the spherical ball and the housing facilitate easy assembly and disassembly.

Application example

"igubal®" rod end bearing as connecting elements for the coupling bars which connect the solar module with the mounting frame.

7... Compact design

Low space requirementsDetails of working principle

By using a plastic plain bearing spherical ball in a housing adjusted for this purpose, all igubal® pillow block bearings have a very compact design. This facilitates the use of fully capable bearings, even in minimum installation spaces, as well as assembly and disassembly in confined situations.

Application example

To achieve the best flying conditions, all components must be lightweight and at the same time as durable as possible. Accordingly, developers have in many cases decided to use igus® products, such as igubal® spherical bearings and igus® energy chains to supply the motor with electrical power.

8... Electrotechnical data

Use in aggressive environmentsDetails of working principle

Both the iglidur® W300 bearing ball and the igumid G housing are resistant against weak alkalis, weak acids as well as against fuels and all types of lubricants. A selection of various materials is available for more demanding needs, such as resistance to chemicals.

Application example

Because the entire robot weight was to be limited to 2 kilogrammes, plastics were the primary choice for this application, including the e-chain® and a host of igus® spherical bearings.

9... Design

High load capacityDetails of working principle

The load carrying capacity of the maintenance-free igubal® bearing elements is very high at normal ambient temperatures. igubal® bearing elements take up high forces and at the same time weigh only a fifth of the common metallic bearing housing. The excellent dampening properties arise as the plastic material of the two-piece bearing can absorb vibrations in contrast to steel.

igus® tested

Application example

Maintenance-free igubal® pedestal bearings are used in theatre seats; they are noiseless and operate reliably even at high loads. In a racing simulator, complex movements can be simulated. Here Teflon bearings were replaced with plastic bearings to significantly increase the service life and reduce the intrinsic noise.

10... calculated online

Service life / wear calculationDetails of working principle

The igubal® expert system allows users to verify the suitability of igubal® bearing elements for their special application. In addition to using various igubal® bearing elements, users can also select from load types (radial/axial and/or static, cyclic, and dynamic).

igus® tested

Entering the application parameters gives you the expected service life for igubal® spherical bearings.

Application example

The igubal® product finder shows you the right spherical bearing solution especially for your application with just a few clicks. To do so, enter some details about the product you want and other factors relevant for you. As a result you will get the best solutions for your application.

11... types of motions

rotating, linear, and oscillatingDetails of working principle

Because the bearing elements are configured as plain bearings, it is possible to use igubal® for oscillating and rotating motions, as well as linear motions in axial direction.

igus® tested

Application example

This machine is used for the improved recycling of domestic waste. It opens refuse bags and roughly pre-sorts the contents. Each machine contains 69 igubal® fl ange bearings, which were chosen on account of their corrosion resistance, lubricant freedom and space-saving design.

12... Spherical design

Fits directly and space-savingDetails of working principle

Because of their spherical design, igubal® spherical bearings are ideally equipped to compensate for shaft misalignments, tilts and bends. In addition, potentially occurring edge loads are almost fully avoided because of the self-adjusting feature. The spherical ball easily accommodates the use with oscillating motions.

igus® tested

Application example

"We were able to realize the application head in the framework preset by data and specifications (requirements, costs) only by the application of the plastic bearings and spherical bearings marked on the drawing. ”

Tilo Lechner / Ludger Pauls, KHS Kisters, Kleve

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!