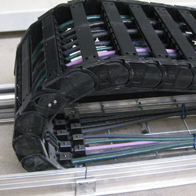

igus® e-chainsystem® P4 - profile rol e-chain®

Safe, quite, abrasion-proof and energy efficient on very long travels up to 800 m and more. Profile rol e-chains® for very high fill weights and speeds. Increase efficiency and reduce energy consumption with the P4 e-chainsystem®.

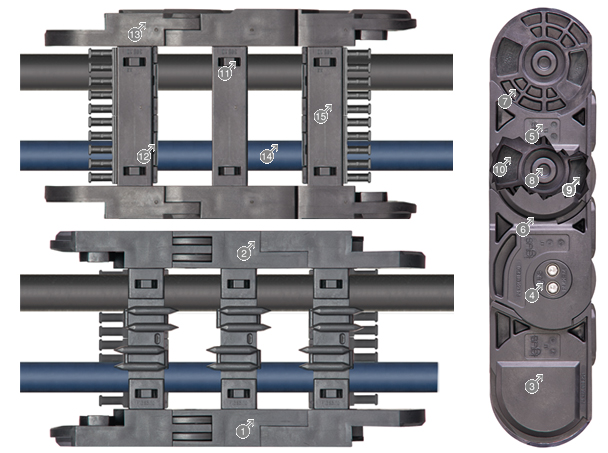

1… Special, split plastic roller

Tribo-optimised, split plastic rollers for all P4 systemsbecause the upper run and lower run are offset, plastic rollers do not roll on top of each other, but instead glide

past each other

… large, level glide surface

"In comparison to standard igus® roller e-chains®: reduced noise, low-vibration operation"

Because the upper and lower run are offset, plastic rollers do not roll on top of each other, but instead glide past each other. Rollers glide on a smooth, level surface for the entire length of the travel path.

igus® tested

Noise and vibration measurement Optimised wear and abrasion. Long service life, improved operating characteristics, reduced noise, damping. "Captive" roller integrated into the side plate.

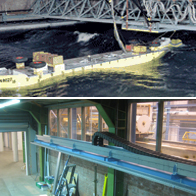

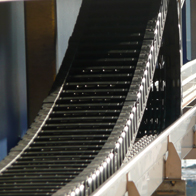

Application example

Cable guide for the trolley drive (130 m) on a container crane with a P4.56R roller chain. Quiet and reliable System P4 at 2.5 m/s travel speed and acceleration of 0.5 m/s². The P4 chain guides various igus® chainflex® cables of type CF300, CF330 single core, CF34 power cable, CF9 control cable and fibre-optic cables CFLG.

2... Comb-like autoglide crossbars

System P4 is securely guided by comb-like autoglide crossbars, even at high speeds and high fill weights (up to 30 kg/m)...Travel speeds up to 10 m/s possible

...accelerations of 50 m/s² and more

Details of working principle

autoglide crossbars provide the needed offset between the upper and lower run, so that the rollers can glide past each other.

igus® tested

Even speeds up to 10 m/s and more are tested on the long-term at the igus® laboratory.

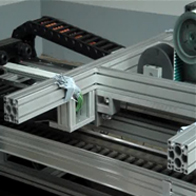

Application example

The P4 roller e-chain® P4.42R stands up to high accelerations (17 m/s²) and speeds (6 m/s) in continuous use on this handling gantry.

3... Wear allowance

For high speeds and guide troughs... lateral wear pads provide for a long service life

Details of working principle

Guide troughs invariably result in lateral contact. The wear allowances ensure a long service life for System P4 even at high speeds.

igus® tested

Abrasion tests at the igus® laboratory. The service life of the e-chains® is tested in endurance tests.

Application example

Cable test rig in a lab. System P4.42R traveling in glide mode at 5 m/s on a 42 m travel with 2.5 kg/m additional load.

4… Same pitch

The pitch for chain links with and without rollers is the same… quiet rolling motion of the e-chain®

… reduced polygon effect

Details of working principle

igus® tested

The uniform pitch of the chain links with and without achieves a quiet rolling motion of the e-chain®.

Application example

Smallest chain from System P4, P4.32. In operation, gliding roller, reverse travel, on 40 m of travel. The chain operates at a speed of 3.5 m/s, at an acceleration of 2 m/s².

5... Few parts, made from one material

Quickly assembled, high dynamics & and no differing material expansion… Accelerations up to 784 m/s²

… same materials

Details of working principle

Few parts and all made from one material - important in high accelerations, as smallest possible clearance/few parts. Same material is optimal in material expansion/shrinking due to temperature differences

igus® tested

Even speeds up to 10 m/s and more are tested on the long-term at the igus® laboratory.

Application example

Test plant for optimising ship drives. A gantry pulls ship models at up to 4 m/s. To prevent influencing the sensitive measurement instruments, a low-vibration e-chain® (System P4.80R) is important even at high accelerations and speeds.

6… Tongue-and-groove design

For torsion rigidity due to "interlocking feature " and highly dynamic, gliding applications…ideal for fast, long travels

... ideal for side-mounted applications or high torsion forces

Details of working principle

The interlocking feature of the chain links ensures very high torsion stability of the e-chain® and prevents links from spreading apart under push/pull forces.

igus® tested

Even speeds up to 10 m/s and more are tested on the long-term at the igus® laboratory.

Application example

System P4 is particularly suited for fast and long travels in confined space applications, such as aisle travel in automated storage and retrieval systems or freezer warehouses. igus® also offers matching chainflex® cables from stock for such highly dynamic applications.

7... Special contour of the links

Smooth-running due to soft unrolling... silent unrolling of the e-chain®, improved installation

Details of working principle

The contour provides for a better unrolling of the e-chain® and for a simpler and secure installation.

igus® tested

The contour of the chain links reduces the polygon effect and thus rolls smoothly. Even the "zigzag" installation type is thereby positively supported.

Application example

Smooth-running due to soft unrolling

8... Large pin/hole connection

High push/pull forces and less wear through precise tolerances...Travels over 800 m possible

...accelerations of 50 m/s² and more

"30% greater pull forces possible when compared to the heavy-duty igus® roller e-chain®."

Details of working principle

More than two stop dogs cannot be, or can barely be synchronized. The rectangular geometry facilitates significantly better force distribution than on a rounded stop dog (formula for surface pressure, p=F/A). The entire P4 family is equipped with dual rectangular stop dogs.

igus® tested

We test every energy supply system with a "tweak testing machine" at the igus® laboratory for compressive/breaking strength to provide reliable specifications on max. additional load and unsupported length

More than 30% tensile strength

Application example

Cable guide for the trolley drive (118,5 m) on a container crane with a P4.56R roller chain. Quiet and reliable System P4 in continuous use at travel speeds of 240 m/min. The P4.56R has an additional load of 2.6 kg/m and is harnessed with the following igus® chainflex® cables, CF330 1x25mm² single core, CF9 12G2.5mm² control cable, CFLG.12G fibre-optic cable and CF11 data cable.

9… noise brake

Dampens noise of the stop dog and rolling… System P4 - noise level of 75 dB at 6 m/s

… many series certified by TÜV Rheinland

"In comparison to the standard igus® roller e-chain®: operating noise reduced by approx. 6 dB(A) due to

improved roller and chain-link geometry"

Details of working principle

Simple principle, but extremely effective. A wedge-shaped contour in the e-chain® stop dog dampens the stop dog noise of the e-chain®.

igus® tested

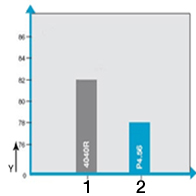

Y= dB(A)

1) 1. profile rol e-chains® from 1999, lab test, v = 2 m/s

2) Outdoor test, v = 6 m/s

respectively 1 m of measurement clearance

Application example

P4 noise measurement in the igus® lab on long travel at a clearance of 1 m to the application.

10...vertical, rectangular stop dogs, large pins

For maximum force absorption and force distribution Therefore allowing higher push/pull forces and loads on long travels (up to 800 m)… push/pull forces possible up to 6500 N

… max. additional loads possible up to 30 kg/m

Details of working principle

More than two stop dogs cannot be, or can barely be synchronized. The rectangular geometry facilitates significantly better force distribution than on a rounded stop dog (formula for surface pressure, p=F/A). The entire P4 family is equipped with dual rectangular stop dogs.

igus® tested

By shifting the stop dogs, the force is guided through three points, namely the two stop dogs and the large pin, instead of absorbing the force centrally. This reduces the load of the individual elements, pins und stop dogs, effectively to 1/3.

Application example

We test every energy supply system with a "tweak testing machine" at the igus® laboratory for compressive/breaking strength to provide reliable specifications on max. additional load and unsupported length. A 1,320 km long test run was completed in an outdoor test at a travel of 120 m and a speed of 6 m/s.

11... Cable-friendly plastic crossbars

For even higher service life of the cables through rounded design… cables will last the longest with plastic opening crossbars

… no plastic deformation from externally applied force

Details of working principle

Smooth, cable-friendly inner contour and rounded crossbars provide for a long service life of the cables and hoses. The interaction of the tribo-optimised plastics of the opening crossbars with the jacket material of the installed cables results in the best service life pairing of tested cables.

igus® tested

Jacket materials of different materials show the best wear results in plastic crossbars. Moreover, compared to aluminum crossbars, these are not subject to plastic deformation with external impact force.

Application example

12... Cable friendly interior separation

For higher service life due to rounded base... nearly halve the cable wear

... less parts, more possibilities

Details of working principle

Smooth, cable-friendly and rounded contour provides for a long service life of the cables and hoses. In addition, a better and more cable-friendly interior separation can now be implemented with less standardized components.

igus® tested

With the new rounded separators, the wear of the cables could be almost halved.

Test 3748Separator 301 compared to new version 45.1

The matching pair of plastic and jacket material also turns out to be the best here.

Application example

In this case, the rounded plastic opening crossbars help to extend the cable service life.

13… wear pads

For a long service life on long travels… 10,000 km and more running performance guaranteed

… for long travels and extended service life

"In comparison to the standard igus® roller e-chain®: 20% more glide surface"

Details of working principle

igus® tested

Every e-chain® achieves at least 10,000 km running performance on long travel - often much more. This is a "promise" that we've been fulfilling since years.

Application example

System P4 in use on the power supply system for a container stacker. The P4.56R travels at 3.3 m/s and an acceleration of 0.3 m/s², across a distance of 112 m. The system guides 3 igus CFCRANE 1x50mm² mid-voltage cables, one CF330 1x120mm² single core, one CF10 7G1.5 and a CFLG.12G fibre-optic cable.

14... 1030 chainflex® cables from stock

The modularity of igus® systems facilitates convenient extending, shortening, expanding, and replacing....from 1 m, no cutting costs, no minimum quantities

… chainflex® works or your money back

Details of working principle

Flexible cables in energy chains® or robots need special characteristics to last through many cycles, high speeds and accelerations, as well as demanding environmental conditions. Yet another requirement is that EMV safety standards, as well as NFPA 79, UL, CSA, VDE, Inter- and Profibus standards are met. The igus® chainflex® product range extends from energy chain compatible control cables, servo cables, motor cables, as well as robot cables, bus cables, data cables, encoder cables and fiber-optic cables.

igus® tested

All chainflex® cables are always tested in practice. This means in the e-chain® or in motion, such as here in the igus® climate chamber at -40°C.

Application example

Since 15 years in long travel distances with a high number of cycles, the Chainflex® cables are added with braiding in bundles, abrasion-resistant, gusset-filling pressure extruded outer jacket They are able to meet even the most demanding needs.

15… Double lock

Guaranteed high holding strength in simple, but secure opening mechanism… max. holding strength up to 2700 N

… can be quickly opened with screwdriver

Details of working principle

Proven and extremely secure snap-open system. You loosen the crossbar by two simple lever movements. The crossbars thus reliably hold even with thick filling and can still be easily opened.

igus® tested

The max. retention force on each opening crossbar is tested in rip-off tests under real-world conditions. This can also take place under the influence of oil or other liquids.

Test 3577Pull-out strength Cross bars: > 2700 N

Application example

P4.80 profile roller chain on long travel with three extension links and high filling. The opening crossbars reliably retain the cable package in the chain.

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!