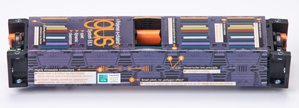

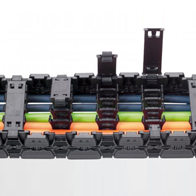

igus® energy chain systems® E6.1 - quiet, clean, fast and stable

System E6.1 is frequently the top choice when e-chains® are needed for cleanrooms, maximum dynamics, or low noise level. The easy accessibility and the high stability for this category render the E6.1 family as a specialist for highly demanding tasks.

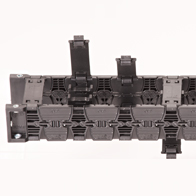

1... Double lock

High retention forces, easy to open... high holding force

... can be quickly opened with screwdriver

Proven and extremely secure snap-open system. You loosen the crossbar by two simple lever movements. The crossbars thus reliably hold even with thick filling and can still be easily opened.

igus® tested

The max. holding force of each crossbar is verified using practical pull-out test. This can also take place under the influence of oil or other liquids.

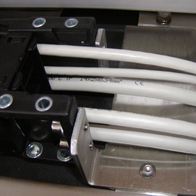

Application example

High accelerations at no vibration and abrasion, and reliable cable seating

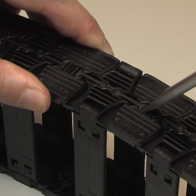

2... Notching on the opening crossbars

For notched separators on applications rotated sidewaysDetails of working principle

The notching in the opening crossbars permits the use of notched separators. These remain reliably in their position even on applications traveling on the side. Cables cannot be crimped.

igus® tested

We conduct long-term tests on all chainflex® cables for wear, and therefore service life, in continuously moving operation. We also test customer-specific cables in order to predict the system service life.

Application example

Numerous chainflex® cables neatly laid and mounted turned 90° in an E6 e-chain®. The interaction of energy chain® material and jacket material is a decisive factor for the service life.

3... Opening crossbars, open from left or right side

For quick insertion of the cables from both sides... easily accessible from above or below

... also pivoting on Series E61.29

Details of working principle

Crossbars on the E61.29 e-chain® are easy to pivot open and completely removable. This helps the easy insertion of cables. The crossbars on other E6.1 Series can be opened from left and right and are removable.

igus® tested

New snap-open mechanism, Series E61.29 optionally snaps open on left or right sides

Application example

Drastically reduce assembly time. Quick insertion of cables and hoses saves valuable assembly time and therefore money.

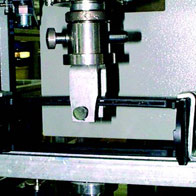

4...Plastic-Metal mounting brackets

Flexible and reliable connection in any direction... Fastening in any direction

... Optionally retrofitted with integrated C rail for installing a strain relief

Details of working principle

Fastening options in any direction – above, below, or front face. Pressed-in steel bushings for a reliable fit. Optimum connection to the e-chain® due to the same shape and material.

igus® tested

Circumferential mounting brackets, optionally with matching strain relief. Flexible mounting options and reliable connection in any direction

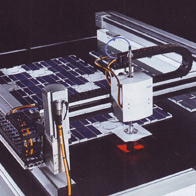

Application example

Mounted on the front-face with customer pre-assembled angle brackets on this large-scale plotter

5.1... Heavy-duty fastener

For long-lasting, reliable force absorptionDetails of working principle

A highly-flexible fastener made from the special purpose material, igumid TE, ensures a reliable, long-lasting connection between E6.1 chain links. The special-purpose material is extremely flexible and is suited for a nearly unlimited number of bending cycles.

igus® tested

Expert opinion: Suitability testing of

igus® energy chains of type E6.29.

for use in pick and place machinery

Expert opinion by the Electrical Energy Technology Institute confirmed that the fasteners reliably last for 1.8 bn cycles. As many as 3.8 bn cycles can be expected.

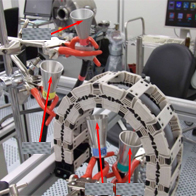

Application example

Machines CD s leeves in a fraction of a second: Tool open, gripper on. Tool closed. All in 0.25 seconds, speed 8 m/s, acceleration: 78.5 m/s2

5.2... Heavy-duty fastener

For low abrasion valuesDetails of working principle

The fasteners between the chain links replace the classic pin/bore connection This drastically reduces abrasion. Applications in rooms with high cleanroom classes become possible.

igus® tested

e-chainssystems® E6.1, certified according to DIN EN ISO Class 1, by the Fraunhofer IPA Institute. About 82% of all chainflex® catalogue cables are certified according to ISO Class 1 or Class 2 IPA . (847 chainflex® cables with tested outer jacket material available from stock)

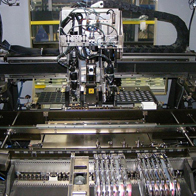

Application example

Micro-processor technology demands an absolutely dust-free environment. In addition to executing pick and place cycles at extreme speeds, this represents a considerable challenge for energy supply systems, which the igus® E6 e-chainsystem® masters in stride.

6... Inner/outer link design

For straight run and high parallelism and high stability... alternating inner and outer links ensure very straight tracking

... accurate parallelism of the e-chain® bands support the long service life

Details of working principle

The alternating inner and outer link mechanism has an enormous advantage. The outside dimensions of both sides are exactly the same size and absolutely parallel.

igus® tested

Inner/outer link design in all E6.1 e-chains®.

Application example

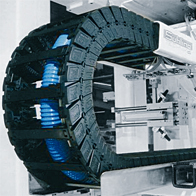

High-speed camera travel requires high stability and smooth e-chain® travel

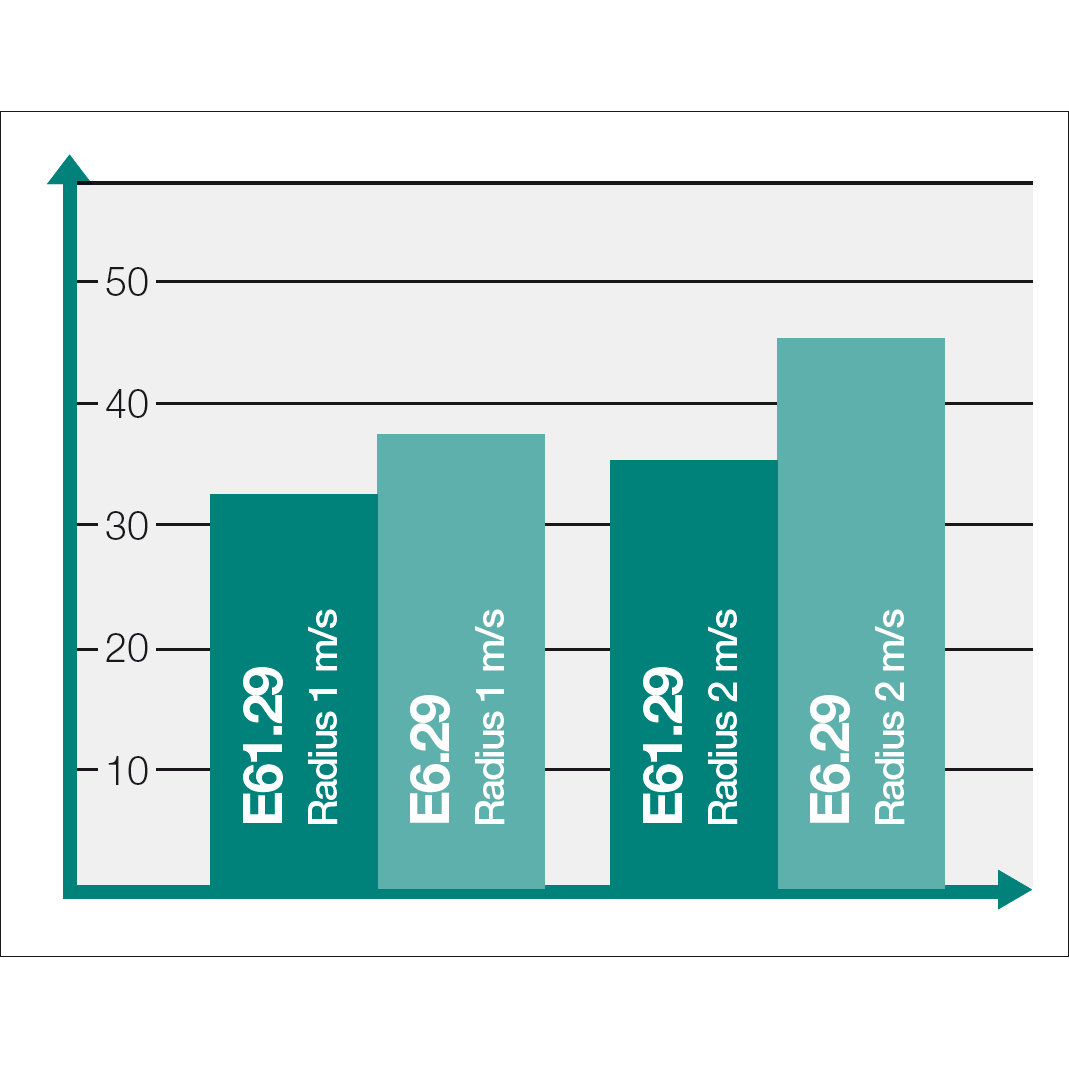

7... Small pitch, quiet run

Low-vibration and very low-noise operation, as low as 33 dB(A)Details of working principle

The "polygon effect" describes that many small elements create a rounder shape than few large ones. The particularly small pitch of the E6.1 ensures very "round" tracking behaviour. This reduces vibration to a minimum and enables maximum precision. At the same time, the rolling noise is significantly reduced.

igus® tested

Series E61.29 was subjected to a sound measurement by the igus® lab with the result that the already good values of the E6.29 were improved by an additional 3 dB(A)

Application example

System E6 is particularly well-suited for plotters and printers, since the quiet and low-vibration operation and cleanroom compatibility guarantee a clean print image.

8... Cable-friendly interior separation

Rounded contours for an increased service-life... nearly halve the cable wear

... less parts, more possibilities

Details of working principle

Smooth, cable-friendly and rounded contour provides for a long service life of the cables and hoses. In addition, a better and more cable-friendly interior separation can now be implemented with less standardized components.

igus® tested

With the new rounded separators, the wear of the cables could be almost halved.

Application example

Here the rounded plastic crossbars assist in increasing the service life of cables

9... opens along the inner and outer radius

For quick insertion of the cables from both sides... easily accessible from above and below

... also pivoting on Series E61.29

Details of working principle

The e-chain® E6.1 has opening crossbars that can be removed along the inner radius as well as the outer radius. This simplifies access to, and the insertion of cables and hoses into the e-chain®.

igus® tested

New snap-open mechanism, Series E61.29 optionally snaps open on left or right sides

Application example

Drastically reduce assembly time. Quick insertion of cables and hoses saves valuable assembly time and therefore money.

10... Cable-friendly plastic crossbars

For even higher service life of the cables through rounded design... Cables have the longest durability with plastic crossbars

... no plastic deformation with external impact force

Details of working principle

Smooth, cable-friendly inner contour and rounded crossbars provide for a long service life of the cables and hoses. The combination of the tribo-optimized plastic of the crossbars with the jacket material of the used cables proves to be the best matching pair for the service life of cables in tests.

igus® tested

Cable wear in plastic crossbars: Jacket materials of different materials show the best wear results in plastic crossbars. Moreover, compared to aluminum crossbars, these are not subject to plastic deformation with external impact force.

Application example

Cable-compatible inner separation and opening crossbars guarantee a long service life for cables and the entire system for this large-scale plotter.

11... Few parts, made from one material

Assembled quickly, high dynamics, and uniform material expansionDetails of working principle

The use of plastic in all components of the energy chain guarantees that the material exhibits uniform behaviour in response to temperature variations. This ensures consistently high precision and dynamics.

igus® tested

Few components for fast assembly. Even tight and uniform tolerances are standard, since all components are made from the same material

Application example

Large-scale printers have extreme demands on constant precision. Vibrations in the energy supply system that can occur due to non-uniform material expansion must be avoided.

12... 1,030 chainflex® cables from stock

from 1 m, no cutting costs, no minimum quantities …

chainflex® works or your money back

Details of working principle

Flexible cables in energy chains or robots need special characteristics to last through many cycles, high speeds and accelerations, as well as demanding environmental conditions. Yet another requirement is that EMV safety standards, as well as NFPA 79, UL, CSA, VDE, Inter- and Profibus standards are met. The igus® chainflex® product range covers energy-chain friendly control cables, servo cables, motor cables, as well as robot cables and also bus cables, data cables, encoder cables and fiber optic cables

igus® tested

All chainflex® cables are always tested in practice. This means in the e-chain® or in motion, such as here in the igus® climate chamber at -40°C.

Application example

Available as a matching cable for cleanroom applications (more than 800 cables with Class 1 or 2 IPA certification) or for reliable functionality in any direction. Machines and plants must be reliably supplied with media, energy, and signals in each individual working position, which requires high durability and reliability of the cables.

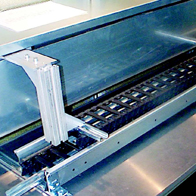

13... Few components, modular design

Can be separated and joined at any locationDetails of working principle

All igus® e-chains® can be assembled and disassembled by hand or with a simple slotted screwdriver. This facilitates chain link replacement at any time and at any position of the e-chain®, and the ability to shorten and extend the e-chain®.

igus® tested

The straightforward design and the fact that a simple screw driver is sufficient for assembly renders igus® e-chain® assembly particularly easy and fast.

Application example

Tests are set up and adjusted with speed and ease. Here is an abrasion test that tests wear on long travels.

14... Small springs on the fasteners

Dampens stop dog contact noiseDetails of working principle

Small tabs on the fasteners between the E6.1 chain links ensure that the contact noise of the links is dampened. This dramatically reduces the noise profile in the e-chain® radius. In combination with the small pitch, this accomplishes the low noise generated by the E6.1.

igus® tested

Study by the Machine Tools Laboratory and Business Operations (WZL) at RWTH Aachen on "Vibration Tests in Energy Supply Chains". Results: The "E6" energy supply system made by igus® GmbH, Cologne, is characterised by extreme low vibration and smooth operation.

Application example

Low-vibration and quiet operation is particularly important on camera applications Vibrations in the image and distracting audio noises must be prevented.

15... Without pretension

With a simple turn of the inner link...solve a no-camber configuration with the same e-chain®

...no (thermal) post-processing, available from stock

Details of working principle

Due to simple turning of the inner links, an e-chain® with pretension can be quickly turned into an NC version. NC versions are needed for special applications, e.g. in suspended applications and confined spaces.

igus® tested

Special products, e.g. for storage and retrieval units, are also tested here, for instance the guidelok slimline F system that prevents the e-chains® from swinging out in storage and retrieval units.

Application example

e-chains® without camber are used in suspended applications, as shown at trade fairs with the guidelok slimline F.

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!