energy chains® for microassembly

Several million work cycles per year with extreme precision in the micrometre range and five years of maintenance-free operation: the Häcker Automation GmbH develops and manufactures micro-assembling machines which satisfy the most demanding requirements, and in the process uses preassembled cables and energy chains® from igus®.

Anyone who already has a new European passport has a product in the wallet which was most likely made with a machine of Häcker Automation GmbH in Schwarzhausen/Thuringia: the 18-axis machine glues a wafer-thin transponder wire that ensures the machine readability on a substrate, fully automatically and at a speed of about 5 m/s.

Those who still travel with the old passport might rely while driving on one or more highly sensitive components that are produced on a Häcker machine: many sensors, e.g. for electronic braking and stabilisation systems (ABS, ESP, etc.), are produced on machines from Schwarzhausen.

Core competence: assembling, dosing and handling in the micrometre range. The examples show Häcker's good repute when it comes to the assembly of sophisticated miniaturised components. Although there are exceptions, such as the assembly of roof windows, for which Häcker has also developed automation solutions, the core competence of the company founded eleven years ago by Gerrit Häcker however lies clearly in the production of highly integrated manufacturing in the micrometre range.

Here the machines achieve impressive accuracies. For example, they reliably mold – supported by a 3D image processing with two camera systems – single bond wires with an accuracy under 20 µm. These accuracies are achieved even in 3D mounting with microcomponents. Gerrit Häcker: "We have developed a modular system for the individual work steps such as gluing, dispensing and placement, which we combine individually. There are 35 different systems available for the assembly process."

Here the highest quality requirements apply. An ESP system in the vehicle, for example, obtains information from twelve or fourteen sensors that must operate with extremely high reliability: failures should not arise here. The machines that Häcker builds for this task produce around 15 million sensors per year with an error rate of well below 1 ppm (parts per million). At the same time, customers expect a very high availability of the machines that run three shifts continuously throughout the year – and they expect flexibility. Even small quantities can be manufactured economically and quickly, without the quality being affected. Gerrit Häcker: "Our machines need to produce the highest quality even with a small lot size and frequent process changeovers."

In complex machinery – the 18-axis machine for the passport production is a good example – such requirements can only be met if one collaborates with selected partners even for the supplied components such as the drives and uses absolutely high-quality components.

This also applies to the energy and data cables that are routed to the gripping, fitting and dispensing units via the x, y and z axis. Häcker pursued, inter alia, the development goal of being able to operate the machine for five years free of maintenance. Jens Beyer, technician in charge of cable assembly at Häcker Automation GmbH: "Our machines complete 5-7 million cycles per year in single shift operation, it can be up to 20 million in 24-hour operation." This means: all moving components including cables must be developed for the extreme application of 100 million motion cycles without maintenance or even replacement.

Häcker found a match for this demanding requirement profile in the igus® cable range, after using other cables that were prone to failure and did not meet the high standards. There is a reason why things are different with the igus® cables. The signal and energy cables of the chainflex® series were specifically designed for use in energy chains® and are characterised by extremely long life with constant stressing through the energy supply movements. New conductor materials as well as special jacket materials are used for them – with the result that the cables when used in energy chains® last many times longer than conventional cables. The dreaded "corkscrewing" followed by core breakage is already avoided by the basic structure of the chainflex® cables – a system that igus® discovered in 1989 and continuously developed since then.

Another design detail: the protective jacket – which the user can choose from seven different materials – is executed with "gusset filling". This means: the jacket envelops not just the cores (then the necessary support for the stranded cores would be missing), but the jacket material is also injected between the core stranding powdered with talc. This ensures that the core stranding does not open by the movement, but can be guided back and forth like in a channel.

These details show: in highly stressed energy chains®, cables that were particularly developed for this application should be used. Häcker uses, inter alia, chainflex® cables of the Series CF 2, CF 10, CF 11, CF 27 and CFPE as a protective conductor and views the selection as excellent, because actually no failures have occurred so far despite the high demands and the millions of movements.

Häcker poses high demands even on energy supply systems: they have to run with low friction and free of vibration at high and low speeds. The compactness also plays a role: the assembly operations are mostly done in a work area of 500 x 500 mm, and a precept of Häcker designers is not to "give away" any installation space for the energy chain®. The energy chains® are also partially integrated in the compact drive and function modules.

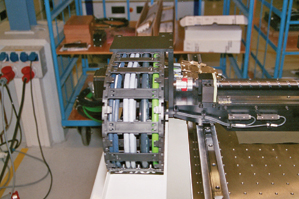

This is a demanding criterion for an energy chain® that moves at a speed of up to 5 m/s and an acceleration up to 40 m/s² with each motion sequence. Jens Beyer: "We also place high demands on the wear behaviour of the chain, since our machines are working mostly in a clean room." Under these conditions, the energy supply chains in the igus® E6 Series prove themselves, which Häcker uses for the linear guiding of the x, y and z axis. These chains are characterised by a very quiet, low-vibration operation – an essential prerequisite in microassembly. And they are extremely durable.

However, it is not just the chain itself which guarantees a long service life of the energy supply system. Detailed work is also always called for here, which igus® and Häcker completed together.

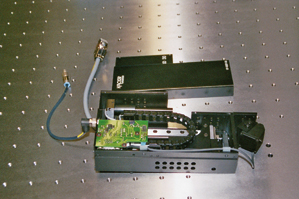

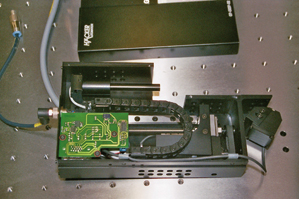

High performance and compact installation space: Häcker develops and manufactures machines for the microassembly of, for instance, sensors and electronic components.

View of the work table of a machine undergoing assembly – energy chains® for the x, y, and z axis are clearly seen.

The energy chains® are also partially integrated in the separate drive and function modules.

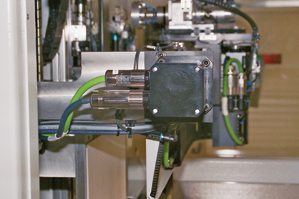

Controlled movement: the arrangement of the cables in the energy chain® requires a lot of detailed work.

Teamwork with excellent results. From left to right: Gerrit Häcker, Managing Director Häcker Automation GmbH, Yve Kirsch, Sales Engineer igus® and Jens Beyer, Technician Häcker Automation GmbH

The energy chains® of the E2 Micro type Series are used even for short strokes.

The fastening of the chain and cables must also be structurally solved optimally in order to meet the high demands on availability and durability.

Jens Beyer: "The cables must be guided optimally in the chain – especially when the chain is tightly packed. The bending radii are to be considered just like the interior separation and an effective strain relief. The cables should not show any movement in the chain, but they mustn’t be fastened. Here, much detailed engineering is necessary, to which igus® extended excellent support." With success: even energy chain systems® with the smallest unroll range of only 50 mm, which, for example, are used in the movement system for the dispensing stroke, achieve the extremely long service life required by Häcker.

This is moreover remarkable since the cables and the energy supply systems are highly stressed due to the high speeds. But the design work that igus® has done for Häcker ensures the high availability for long periods. Thereby, compelling solutions have also been developed for specific requirements – for example, after laboratory tests igus® can provide an energy chain® compatible PE cable with a 1.5 mm2 cross section for the energy chain systems® for Häcker.

Chain fastening is included in the detailed work, which has been structurally integrated in the energy supply system, and the selection of cables. The high lifetime requirements make it necessary that only tested components are mounted. This applies to both the energy chain® and the cables that are obtained from igus®, assembled as readycable®. Then the assembly staff in Schwarzhausen need not perform the finishing work and can immediately connect the complete cable set including plug connectors. This saves time, and that counts for Häcker: only a throughput time of ten days is estimated for the construction of a machine.

More information

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!