Compactly built and 3D-movable

Energy supply for robotic systems in automotive welding and assembly lines.

Harsh operating conditions, little space – with high acceleration forces and number of cycles that affect the energy supply. In the past, it led to expensive downtimes of the handling robot, accruing to a six-digit sum per year. No wonder that MA Automotive Deutschland GmbH changed over to compactly built, three-dimensionally moving "triflex® RS" energy chain systems®. Since then, the plant availability has increased significantly.

"Three pressing and eight structural work lines as well as a hundred robots are in use," Steffen Modes, head of structural work maintenance at MA Automotive Deutschland in Treuen, Saxony, describes the highly complex machinery. The company belongs to CLN Holding (including MA Automotive), the largest steel service centre in Italy based in Turin. The Group has 34 locations in Europe and two production sites overseas.

Since the factory opened in 2004, the location in Vogtland focuses on the production of individual, structural and outer body panels made of steel and aluminium with about 185 employees. "We see ourselves as a quality partner to our customers in the domestic and international automotive industry," Steffen Modes explains the philosophy of the supplier company.

Fully automated robotic systems rule the automotive welding and assembly lines. In one area, a robot is responsible for the handling of rear lids. Here, unforeseen plant shutdowns happened repeatedly in the past, as the factory hose assembly mounted on the robot could not withstand the tight conditions and circumstances on site. It stuck, got caught and tore off time and again. "On average, the entire system was shut down for 657 minutes in a year. This meant we incurred costs of EUR 100,000 a year. It was not sustainable over time," says Steffen Modes," so we strengthened the search for the remedy.

The robot uses a total of eight different stations in the plant. It picks up the separate items very accurately in the devices, leads it to other devices, before it finally de-stacks the rear lids in two tank towers. "By placement, we are talking of collision values of up to 3 cm," illustrates Modes the extremely limited space on site. The key requirements for energy supply are constituted accordingly. The energy chain system® must have a very high tensile strength and the lowest possible dead weight. At a high acceleration from 0 to 2 m/s, it also needs to withstand very high forces. In addition, most adverse environmental conditions apply, such as extremely high welding dust.

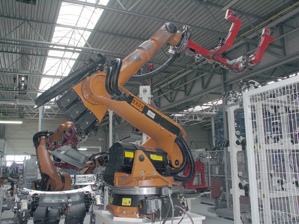

Energy supply systems from igus® GmbH from Cologne, Germany have been in use since spring 2008. The project uses the triflex® RS system, a compact universal module in which energy chains are guided in a space-saving way parallel to and close to the robot arm. It can be installed easily and quickly on all existing mounting points on the robot, regardless of whether it is on the side or on top. Thanks to its very low installation height and slender chain guidance, the triflex® RS allows for all robot movements to be performed reliably even in the tightest installation spaces.

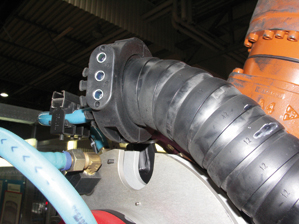

The grease-free energy chain system® has an integrated retaining spring. By the use of the fibre rods plugged into the fibre rod modules, a directed pretension is automatically generated. "These pull-back mechanisms are similar to those of a fishing rod and keep the energy chain® always under tension," explains Yve Kirsch, technical sales consultant in the igus® office in Thuringia. "In this way, the chain is always guided close to the robot head even in complex three-dimensional movements to prevent loops and cable stress. " Getting caught on tools, tool carriers or other interfering edges cannot happen.

"In total, there were four robotic problems, in all of which we had to contend with extremely tight spaces," says Steffen Modes. "They were all by and by retrofitted with the "triflex® R" sets from igus® and today we have no more trouble. The earlier plant downtimes are a thing of the past, all the robots run completely trouble-free for the last 18 months. " The investment was earned back within a short time. Since the retrofit, 1,380,000 cycles have already been completed.

Resistant to impact and abrasion, rugged and dirt-repellent The four robots of the automotive supplier are equipped with the "triflex® R" energy chain®, in the enclosed version "triflex® TRC70". The energy supply system ensures high flexibility in complex movements even in the 6th axis. Each chain link can be twisted in the longitudinal axis by about +/- 10°. This supports the guiding of cables around difficult geometric shapes.

High tensile strength absorption takes place through the so-called "trailer principle" (similar to the "ball and socket" mechanism). Socket and ball form an extremely flexible connection after snapping in place, combining the smooth movement in all three axes with optimum traction, and thus guaranteeing a high tensile strength. A torsion of the longitudinal axis up to +/- 380° per metre is possible. Both in the radius and in the torsional motion, the "triflex® R" energy chain offers an ideal bending radius for cables due to its integrated stop system. Finally, the universal mobility of the entire system also enables a fast teach-in.

Another point is the excellent mechanical properties of the energy chain. Resistant to impact and abrasion, sturdy and dirt-repellent, it resists the ubiquitous welding dust in the harsh environment. Setup times are minimised by a simple connection and matching accessories, in this case, such as strain relief systems and clamps.

"We had the first energy supply system installed by igus®," Steffen Modes looks back. "For this, there was a time window of up to eight hours a day, after which the robot had to walk again. Everything worked so smoothly that we carried out the retrofit of the other three robots ourselves.

In times of tight budgets, the head of maintenance surely had to first write a detailed request to get the funds approved for conversion. The economic figures also quickly gave a clear, very firm recommendation in favour of the conversion. "With an annual standstill of about eleven hours – which is equivalent to the cost of more than one shift! – The management became convinced very quickly," said Modes. At an appointment on site, the igus® energy chain systems® sales representative, Yve Kirsch, showed the system. Then they jointly sought the best implementation technically and economically. The past few months show that it was found: from day one since the installation, the multidimensionally movable energy supply system has stood the test with the new universal module.

Compact on the robot: Multidimensionally movable "triflex® R" energy supply system with compact universal module. 200 rear lids are processed in MA Automotive Deutschland per shift.

The collision values while handling the rear lids are sometimes a maximum of 3 cm.

The energy chain system® has an integrated retaining spring. Thus a directed pretension is always automatically built up so that no loops and cable stress occur on the robot head during fast movements.

The universal module "triflex® RS" can be directly mounted on all existing mounting points of the robot. Thus all 3D movements are safely and compactly implemented even in a very small space.

Support for dynamic applications: The energy chains® mounting bracket with strain relief.

Resistant to impact and abrasion: Protectors offer additional protection in extreme robotic movements.

Steffen Modes of MA Automotive Deutschland (left), Yve Kirsch of igus® office in Thuringia. Since the retrofit, the head of maintenance Steffen Modes has been saving downtime costs in six digits every year.

More information

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!