The bearing for a rotating motion (counter partner made from fibreglass reinforced PP rotates at 100 RPM) in 50°C hot water and cleaning media developed problems after only 25% of the expected service life. Wear in the form of small fragments results in shortening of the bushing. Because of the high chemical resistance of the material, the customer excluded the cleaning media as the cause.

The igus® test lab used original parts from the customer to create a realistic copy of the application, and started testing with various materials.

The results were clear after only a few days: Only the combination of vibrations and chemicals results in bearing damage. By concurrently testing several other iglidur® plain bearings, iglidur® J emerged as the suitable bearing material.

Customer-specific test by the dry-tech® lab finds the cause and solution for bearing failure

Conclusion:

Several iglidur® alternatives were tested concurrently during the customer-specific test. iglidur® J was ultimately recommended as the price-performance winner for this application.

Do you wish to test a custom application?

We will gladly test your specific application as well. Simply use the contact form!

More information:

iglidur® J - Material data

iglidur® J - The fast- and slow-motion specialist

dry -tech® test laboratory

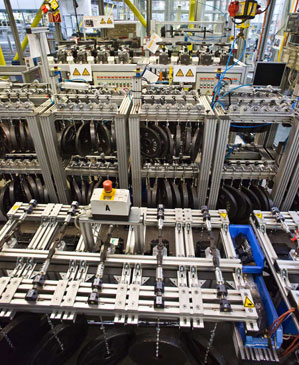

In the dry-tech® test laboratory, over 135 trillion test movements are executed every year

More than 100,000 products available! Delivery and Customer Service Mon-Fri from 8am-8pm and Sat from 8am-12pm!