drylin® productfinder

Productfinder for leadscrew modules, toothed belt axes and tube adjustments.

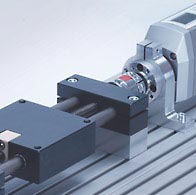

The drylin® product portfolio provides lubricant-free linear axles that are driven either by trapezoidal thread, steep thread or toothed belt. The user can choose a suitable individual solution from lightweight solid plastic units up to massive stainless steel solutions. In all systems, the stroke length is freely selectable and the drive implemented either via hand wheel or motor.

Main body made of stainless steel, aluminum, zinc or plastic

2Lubrication-free through polymer bearings and polymer nuts

33 shaft materials

4Carriages made of anodized aluminum or solid polymer

58 trapezoidal thread pitches 4 steep thread pitches

6Spindle machining according to drawings or spindle pin Steel, stainless steel or aluminum spindles

Position indicator, clamping and hand wheels available

| Glider material: | iglidur® J |

| Shaft materials: | Alu, hard andonized

Cf53 stainless steel |

| Spindle material: | Steel

Stainless steel Aluminum, hard-anodized |

For format adjustments

In extreme environments

When a cost-effective, ready-to-install solution is desired

When corrosion resistance is required

When it should be low noise

When high loads should move highly dynamically

When positioning accuracy < 0.1 mm is necessary

If high running performance is required in continuous operation

Productfinder for leadscrew modules, toothed belt axes and tube adjustments.

SHT – the standard

SHT – the standardSolid design

Three different installation sizes

Various materials for shaft and spindle

Maintenance-free and corrosion-resistant

TR 10 x 2, TR 18 x 4, TR 24 x 5

SHT-PL "Preload"

SHT-PL "Preload"Prestressed trapezoidal nut, preload force: 50 N

Manually and continuously adjustable radial clearance

Tapered off spindle end enables operation by hand wheel or motor

SHTC Compact

SHTC CompactHigh flexibility

Ideal for 2 carriages

Maintenance-free, self lubricating

Adjustable bearing clearance

SHTS High speed

SHTS High speedPitch 10 x 12, 10 x 50, 18 x 100

Steep-threaded spindle

High-Speed-solution

Maintenance-free, self lubricating

SHT lift table with quick release

SHT lift table with quick releaseAluminum version

For fast format adjustments

Brake by interlocking included

Freely selectable stroke lengths

Lubricant- and maintenance-free

High precision independent of load

Self-adjusting

Quiet

Resistant to corrosion

SHT-BB leadscrew module with ball-bearing mounted spindle

SHT-BB leadscrew module with ball-bearing mounted spindleHigher RPMs, increased precision

Belt drive permits radial loads

Constant torque

Reduced axial clearance

SHT – HTX high temperature

SHT – HTX high temperaturehigh temperature til +180°C

Shaft and spindle made of stainless steel

Bearing material iglidur® X

Carriage and traverses made of anodised aluminum

SHTC - HYD Hygienic Design

SHTC - HYD Hygienic DesignEasy-to-rinse solution

Bolted connections are easily accessible and generously designed for clearances

Materials: Plastic and VA stainless steel

SHTP mini - small and low-priced

SHTP mini - small and low-pricedMiniature version

Very low weight

Very low priced

Corrossion-resistant

Carriages and shaft end supports

made of high-performance polymers SHTP - Economical

SHTP - EconomicalSolid polymer design

Low weight

Low priced

Corrossion-resistant

SHTP leadscrew module with quick release

SHTP leadscrew module with quick releaselighter solid polymer model

For fast format adjustments

Brake by interlocking included

Freely selectable stroke lengths

SLW - The compact one

SLW - The compact oneFlat and compact

High torsional stability (stiffening)

Completely supported

Hard anodized aluminium rail

SLWE – PL - preload

SLWE – PL - preloadFlat and compact

High torsional stability (stiffening)

Completely supported

Hard anodized aluminium rail

SLWE-BB ball-bearing

SLWE-BB ball-bearingLower drive force

Minimized clearance up to 1500 rev/min (according to length and load)

Quiet operation – reduced vibration of the overall system

SLWS - compact with steep thread

SLWS - compact with steep threadPitch 8 x 15 mm

Flat and compact

High torsional stability (stiffening)

Hard anodized aluminium rail

SAW – linear modul

SAW – linear modulTrapezoidal or high helix spindle

Threaded drive spindle with ball bearing

Rail extrusion with high profile form factor, extremely torsion resistant

SLW-ES – stainless steel version

SLW-ES – stainless steel version Stainless steel version with corrosion-resistant steel components (1.42305, 1.4408 or 1.4571)

Bearing material selectable

drylin® W profile rail as a protective mechanism

Available with pitch 10x2, 10x12 or 10x50

Compact design

3 carriage lengths

Different lead screw pitches can be combined

Separate manual adjustment of carriages

Lubrication-free linear guide drylin® W

Operation either manual or motorised

Space-saving sensor integrated in the carriage

Operation without mains supply

Integrated magnetic tape

Lubricant-free operation

Extensive accessories available

Small (installation height from 22 mm), light and flat

for manual operation with hand wheel

Small (installation height from 22 mm), light and flat

motorized operation

SLW - cross slide

SLW - cross slideLow cost cross slide solution for manual adjustments

lubricant-free and corrosion resistant

Maximum stroke length in XY tables 300 mm

SLW - cross slide - stainless steel

SLW - cross slide - stainless steelFor manual adjustments

Flat and compact

All construction materials: VA and V4A stainless steel

Resistant to chemicals and corrosion

SHT/SHT-PL - cross slide

SHT/SHT-PL - cross slideHigh precision, extreme stiffening and precise alignment through CNC production

Available as standard and preload version

Mounting of upper unit with right or left alignment possible

Ready-to-connect SAW for step motor

Ready-to-connect SAW for step motorFor your step motor

Type NEMA-23

Threaded drive spindle, ball-bearing mounted

Pitches 2 mm, 3 mm, 12 mm or 50 mm per rotation

Compact design, low weight, high stability

Fast and easy coupling of your motor with the maintenance-free DryLin® linear units. Spacer, motor flange and coupling form a construction kit for the easy installation of your NEMA23.

Cursor

Cursor Plastic analog display for the adjustment and direct reading of the carriage position.

Spindle clamp

Spindle clamp Shaft clamping flange to be mounted on the cursor for a clamping of the threaded spindle.

Hand wheel

Hand wheelHand wheel to be mounted at the end of the threaded spindle. Various types of handles available.

V-drive

V-driveThe DryLin® SHT-WT angular drives offer maximum flexibility in positioning.

Bracket kit

Bracket kitDryLin® SHT-WS is the new angle kit for the SHT linear sliding tables range.

Smart solution for long stroke lengths of the SLW linear modules

drylin® E - product overview

drylin® E - product overviewThe consistant development of the toolbox and system concept of the lubrication-free drylin® drive technology.

High dirt-resistance

Cost-effective and reliable

Modular design, permits simple installation

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!