What is speedigus®?

At igus, we have the aim of helping our customers reduce costs while bringing technical benefits to their products and machines. We call this "plastics for longer life."

Sometimes our customers require custom parts or services, and for many years this has been an important part of the igus® support

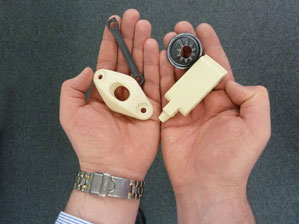

Now, with speedigus®, we combine custom parts with speed, using the benefits of igus® tribo-plastics.

speedigus® custom parts can be manufactured in three distinct ways: