iglidur® - Maintenance-free flange bearing

With this design it is possible to use the iglidur® high-performance bearings where housing bores with no precise tolerances are possible.

When you want a screw flanged bearing

When a clip bearing solution is not satisfactory as a sheet metal feedthrough

When there is a housing with very rough tolerances

When the tight fit of a press-fit bearing is not sufficient as an axial securing

When an additional angle compensation is required

igubal® flange bearing

When a screw connection is not possible

iglidur® clip bearing

When a large guide length is necessary

iglidur® G

With this design it is possible to use the iglidur® high-performance bearings where housing bores with no precise tolerances are possible. The design enables high loads with minimum demand on the precision of the housing. iglidur® maintenance-free flange bearings are available in four materials - iglidur® G, iglidur® J, iglidur® X and iglidur® A180. Thus, with this design, a very wide range of applications - from the universal bearing through the highest wear resistance or temperature resistance (up to +250°C) up to FDA-compliant bearing solutions - can be covered.

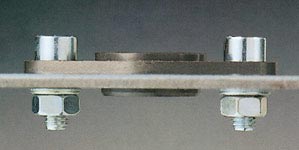

Dependent on the stressing capacities, various mounting types are used. For low radial loads, it is enough to mount the iglidur® flange bearing with just two screws on a surface. For higher radial loads, it is advisable to support the iglidur® flange bearing in a bore on the reinforced side in the load direction. Large tolerances are permitted for this bore, as it is only to additionally support the iglidur® flange bearing. In order to support still higher radial loads, the iglidur® flange bearing can be press-fitted with the longer side in an H tolerance bore. The additional screw connection secures the firm seating of the bearing in the housing. For the mounting of the iglidur® maintenance-free flange bearing, no special tools or devices are necessary. The alignment of the bearing in multiple mounted shafts is easily possible at the installation.

Available materials: iglidur® G, iglidur® A180, iglidur® J and iglidur® X

The mounting of the iglidur® flange bearing: Simple and safe

|

Part No.: |

|

| d1 [mm]: | |

| Part No. | iglidur® material | d1* | d2** | d3 | d4 | d5 | d6 | d7 (+/- 0,2) | b1 | b2 | b3 | R | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

GFL-10 GFL-10 |

G | 10 | 12 | 30 | 14 | 15 | 4.5 | 22 | 6 | 2 | 1 | 4 | 3.34 USD |  |

GFL-12 GFL-12 |

G | 12 | 14 | 36 | 16 | 18 | 4.5 | 26 | 6 | 2 | 1 | 4.5 | 3.77 USD |  |

GFL-14 GFL-14 |

G | 14 | 16 | 42 | 18 | 21 | 5.5 | 30 | 6 | 2 | 1 | 5 | 4.01 USD |  |

GFL-16 GFL-16 |

G | 16 | 18 | 48 | 20 | 24 | 5.5 | 34 | 6 | 2 | 1 | 5.5 | 4.13 USD |  |

GFL-18 GFL-18 |

G | 18 | 20 | 54 | 22 | 27 | 6.5 | 39 | 6 | 2 | 1 | 7 | 4.37 USD |  |

GFL-20 GFL-20 |

G | 20 | 23 | 60 | 26 | 30 | 6.5 | 44 | 10 | 3 | 2 | 7 | 4.62 USD |  |

GFL-25 GFL-25 |

G | 25 | 28 | 75 | 30 | 35 | 6.5 | 55 | 10 | 3 | 2 | 8.5 | 5.83 USD |  |

GFL-30 GFL-30 |

G | 30 | 34 | 90 | 36 | 40 | 8.5 | 66 | 10 | 3 | 2 | 10 | 10.51 USD |  |

GFL-35 GFL-35 |

G | 35 | 39 | 95 | 41 | 55 | 8.5 | 77 | 10 | 3 | 2 | 12 | Upon request |  |

A180FL-10 A180FL-10 |

A180 | 10 | 12 | 30 | 14 | 15 | 4.5 | 22 | 6 | 2 | 1 | 4 | Upon request |  |

A180FL-12 A180FL-12 |

A180 | 12 | 14 | 36 | 16 | 18 | 4.5 | 26 | 6 | 2 | 1 | 4.5 | Upon request |  |

A180FL-16 A180FL-16 |

A180 | 16 | 18 | 48 | 20 | 24 | 5.5 | 34 | 6 | 2 | 1 | 5.5 | Upon request |  |

A180FL-20 A180FL-20 |

A180 | 20 | 23 | 60 | 26 | 30 | 6.5 | 44 | 10 | 3 | 2 | 7 | Upon request |  |

A180FL-25 A180FL-25 |

A180 | 25 | 28 | 75 | 30 | 35 | 6.5 | 55 | 10 | 3 | 2 | 8.5 | Upon request |  |

A180FL-30 A180FL-30 |

A180 | 30 | 34 | 90 | 36 | 40 | 8.5 | 66 | 10 | 3 | 2 | 10 | Upon request |  |

A180FL-35 A180FL-35 |

A180 | 35 | 39 | 95 | 41 | 55 | 8.5 | 77 | 10 | 3 | 2 | 12 | Upon request |  |

JFL-10 JFL-10 |

J | 10 | 12 | 30 | 14 | 15 | 4.5 | 22 | 6 | 2 | 1 | 4 | Upon request |  |

JFL-14 JFL-14 |

J | 14 | 16 | 42 | 18 | 21 | 5.5 | 30 | 6 | 2 | 1 | 5 | Upon request |  |

JFL-16 JFL-16 |

J | 16 | 18 | 48 | 20 | 24 | 5.5 | 34 | 6 | 2 | 1 | 5.5 | Upon request |  |

JFL-20 JFL-20 |

J | 20 | 23 | 60 | 26 | 30 | 6.5 | 44 | 10 | 3 | 2 | 7 | Upon request |  |

JFL-25 JFL-25 |

J | 25 | 28 | 75 | 30 | 35 | 6.5 | 55 | 10 | 3 | 2 | 8.5 | Upon request |  |

JFL-30 JFL-30 |

J | 30 | 34 | 90 | 36 | 40 | 8.5 | 66 | 10 | 3 | 2 | 10 | Upon request |  |

JFL-35 JFL-35 |

J | 35 | 39 | 95 | 41 | 55 | 8.5 | 77 | 10 | 3 | 2 | 12 | Upon request |  |

XFL-10 XFL-10 |

X | 10 | 12 | 30 | 14 | 15 | 4.5 | 22 | 6 | 2 | 1 | 4 | Upon request |  |

XFL-12 XFL-12 |

X | 12 | 14 | 36 | 16 | 18 | 4.5 | 26 | 6 | 2 | 1 | 4.5 | Upon request |  |

XFL-16 XFL-16 |

X | 16 | 18 | 48 | 20 | 24 | 5.5 | 34 | 6 | 2 | 1 | 5.5 | Upon request |  |

XFL-20 XFL-20 |

X | 20 | 23 | 60 | 26 | 30 | 6.5 | 44 | 10 | 3 | 2 | 7 | Upon request |  |

XFL-25 XFL-25 |

X | 25 | 28 | 75 | 30 | 35 | 6.5 | 55 | 10 | 3 | 2 | 8.5 | Upon request |  |

XFL-30 XFL-30 |

X | 30 | 34 | 90 | 36 | 40 | 8.5 | 66 | 10 | 3 | 2 | 10 | Upon request |  |

XFL-35 XFL-35 |

X | 35 | 39 | 95 | 41 | 55 | 8.5 | 77 | 10 | 3 | 2 | 12 | Upon request |  |

| More about selected part: | ||||||||||||||

3D-CAD Sample request

Sample request PDF

PDF Quote request

Quote request Price list

Price list myCatalog

myCatalog

|

||||||||||||||

**Press-fit in housing bore with H7 tolerance

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!